o rings rubber seals manufacturers

The Importance of O-Rings and Rubber Seals in Various Industries

O-rings and rubber seals are integral components in many industrial applications, providing critical sealing solutions that prevent leaks and maintain the integrity of systems. These versatile elements are used in a wide range of industries, including automotive, aerospace, manufacturing, and oil and gas. This article explores the significance of O-rings and rubber seals, the manufacturing process, and the factors to consider when choosing a manufacturer.

Understanding O-Rings and Rubber Seals

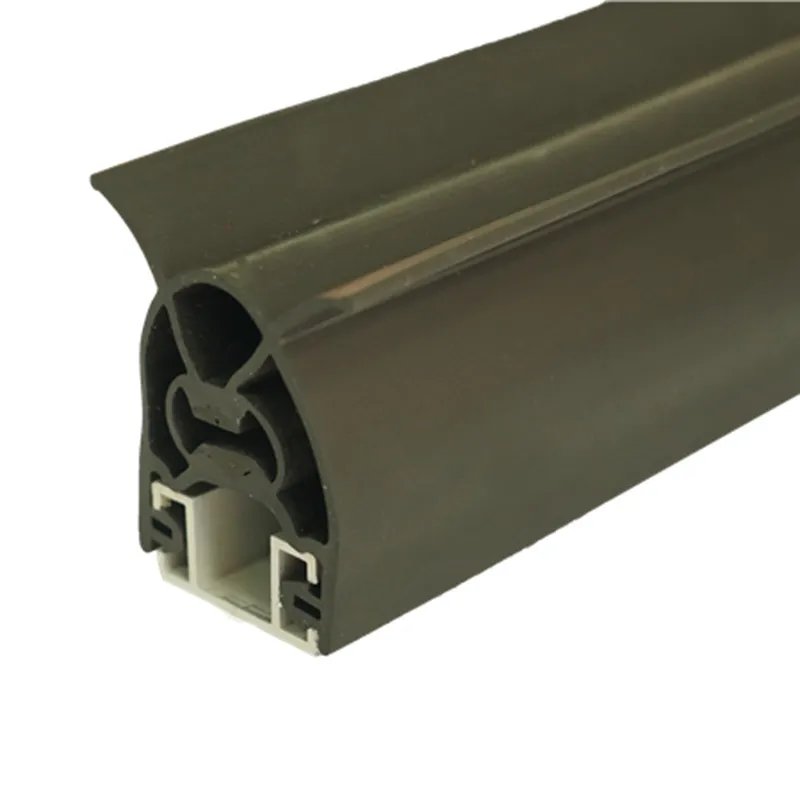

O-rings are circular rings made from elastic materials that can fit into a groove to create a seal. They are designed to prevent the passage of fluids or gas between mating surfaces. Rubber seals, on the other hand, can come in various shapes and sizes, including flat gaskets and custom-tapered designs. Both components are essential for ensuring the efficiency and safety of machinery, devices, and various applications.

Applications Across Industries

1. Automotive Industry O-rings are widely used in automotive applications, including engine components, fuel systems, and hydraulic systems. They help maintain pressure and prevent leaks, which is crucial for optimal engine performance and safety.

2. Aerospace The aerospace sector demands high-performance seals that can withstand extreme temperatures, pressures, and harsh chemicals. O-rings are used in fuel systems, landing gear, and engines to ensure reliability and safety in flight.

3. Manufacturing In manufacturing processes, rubber seals can be found in hydraulic cylinders, pumps, and various machinery components. Their ability to provide a tight seal under pressure is essential for efficient operation and preventing contamination.

4. Oil and Gas O-rings and rubber seals play a critical role in the oil and gas industry, where sealing solutions must withstand high pressures and corrosive environments. They are used in drilling equipment, pipelines, and valves, ensuring that operations run smoothly and safely.

Manufacturing Process

The manufacturing of O-rings and rubber seals involves several steps

o rings rubber seals manufacturers

2. Molding The selected rubber compound is placed into molds specifically designed for the desired shape and size of the O-ring or seal. Compression molding, transfer molding, and injection molding are common techniques.

3. Curing The molded parts undergo a curing process, known as vulcanization, where heat and pressure are applied to create cross-links in the rubber, enhancing its strength and elasticity.

4. Quality Control After curing, O-rings and rubber seals are inspected for defects, precision, and performance. Testing for compression set, tensile strength, and leakage is common to ensure that they meet industry standards.

Choosing the Right Manufacturer

When selecting a manufacturer for O-rings and rubber seals, several factors should be considered

- Experience and Expertise Look for manufacturers with a proven track record in producing high-quality sealing solutions for your specific industry.

- Material Options Ensure the manufacturer offers a wide range of materials to meet your needs, especially if your applications require specialized compounds.

- Customization Capabilities Many applications require custom shapes and sizes. Opt for manufacturers that provide tailored solutions to fit your specific requirements.

- Certifications Check if the manufacturer complies with industry standards and certifications, such as ISO, which ensures product quality and reliability.

- Customer Support Good customer service is crucial, especially if you need assistance with product selection or technical queries.

In conclusion, O-rings and rubber seals are vital components across various industries. Understanding their applications, manufacturing processes, and the criteria for selecting a manufacturer can help businesses make informed decisions, ensuring they choose the right sealing solutions for their needs. Whether for automotive, aerospace, or industrial applications, the right O-rings and rubber seals can enhance performance, efficiency, and safety in operations.

Share

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025