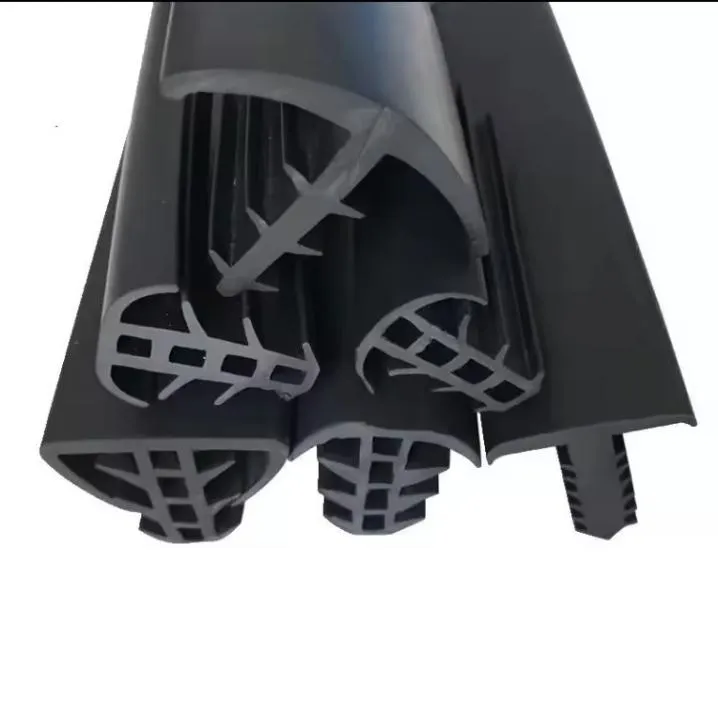

rubber seal production for door bottom manufacturers and suppliers in the industry

The Importance of Rubber Seal Bottoms for Doors A Look at Manufacturing

In today’s fast-paced world, the importance of energy efficiency and sustainability is at the forefront of architectural design and construction. One often overlooked component that plays a pivotal role in enhancing thermal insulation and reducing energy consumption is the rubber seal at the bottom of doors. As the demand for effective sealing solutions grows, the manufacturing of rubber seal bottoms has evolved into a specialized industry, with numerous factories focusing on producing high-quality products.

What is a Rubber Seal Bottom for Doors?

A rubber seal bottom for doors, commonly referred to as a door sweep or weatherstrip, is a strip of flexible material designed to fit along the bottom edge of a door. Its primary function is to prevent air leaks, water intrusion, and the entry of dust and insects, thus creating a more comfortable and energy-efficient indoor environment.

Benefits of Rubber Seal Bottoms

1. Energy Efficiency The most significant advantage of installing rubber seals at the bottom of doors is improved energy efficiency. By minimizing drafts and ensuring a tighter seal, rubber seals help to maintain the desired indoor temperature. This results in reduced reliance on heating and cooling systems, leading to lower energy bills.

2. Noise Reduction Apart from energy savings, rubber seal bottoms also play an essential role in soundproofing. They help dampen the sound that travels through gaps underneath doors, making living and working environments quieter and more peaceful.

3. Weather Resistance Rubber seals are designed to withstand various weather conditions. They provide a barrier against rain, snow, and wind, protecting the interior of buildings from potential water damage and the effects of extreme weather.

4. Enhanced Aesthetics Rubber seals come in various colors and styles, allowing them to blend seamlessly with different door designs. This aesthetic flexibility ensures that functionality does not compromise the overall look of the door.

The Manufacturing Process

rubber seal bottom of door factories

The production of rubber seal bottoms involves several key steps, ensuring that the final product meets industry standards for durability and effectiveness.

1. Material Selection Quality rubber is essential for manufacturing durable door seals. Manufacturers often use materials such as EPDM (Ethylene Propylene Diene Monomer), which possess excellent weather-resistance capabilities and flexibility.

2. Molding The selected rubber is then processed through a molding technique, often using compression or extrusion methods. This allows manufacturers to create seals that are custom-fit for various door sizes and styles.

3. Quality Control After molding, each batch of rubber seals undergoes rigorous quality control tests. This process includes checking for durability, flexibility, and insulation properties to ensure that the product complies with safety and performance standards.

4. Packaging and Distribution Once approved, the rubber seals are packaged and prepared for distribution. Manufacturers often collaborate with retailers, contractors, and construction companies to ensure that their products reach the end-users efficiently.

The Future of Rubber Seal Manufacturing

As environmental concerns continue to rise, the rubber seal industry is poised for growth. Manufacturers are increasingly focusing on sustainable practices, utilizing recyclable materials, and adopting eco-friendly production methods. Advances in technology, such as the use of precision molding and automated quality control systems, are enhancing production efficiency while maintaining high quality.

Additionally, as smart home technology gains popularity, there may be opportunities for integrating advanced sealing systems that can further optimize energy efficiency. For instance, seals that can automatically adjust based on the weather or the home’s needs could become a reality.

Conclusion

Rubber seal bottoms for doors may seem like a small component in the grand design of a building, but their impact is significant. They play a crucial role in enhancing energy efficiency, reducing noise, and improving overall indoor comfort. As manufacturing processes evolve and environmental considerations take center stage, the importance of high-quality rubber seals will only increase. For builders, architects, and homeowners, investing in these products promises not just immediate benefits but also a long-term contribution to sustainability and comfort.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025