Lithium Ion Battery Assembly Machine Boosts Production Efficiency

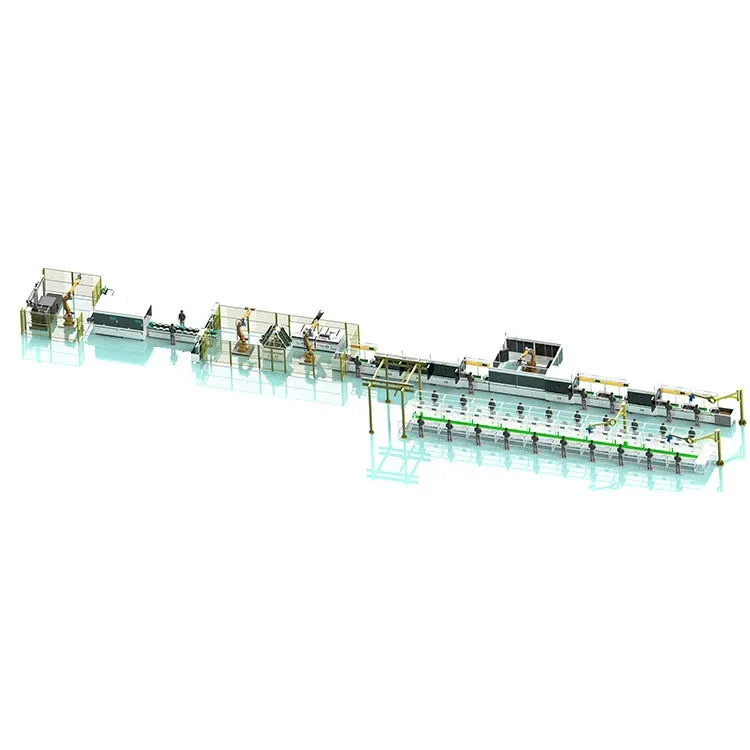

In the fast-paced landscape of lithium battery manufacturing, optimizing production efficiency is key to staying competitive. Xingtai Shuoding Trading Co., Ltd., a prominent name among battery assembly line manufacturers, offers advanced lithium ion battery assembly machine solutions that revolutionize production processes. Complemented by our high-performance lithium battery welding machine systems, we provide comprehensive solutions that streamline operations, reduce downtime, and enhance output quality. Our commitment to innovation and reliability makes us a trusted partner for manufacturers seeking to maximize efficiency in their lithium battery production lines.

Xingtai Shuoding Trading Co., Ltd.’s Expertise in Lithium Ion Battery Assembly Machines

Xingtai Shuoding Trading Co., Ltd. has established itself as a leading provider of lithium ion battery assembly machine solutions. With years of industry experience, our team of engineers designs machines that combine precision, speed, and durability. We understand the unique challenges of lithium battery production, from cell handling to final assembly, and our lithium ion battery assembly machine models are engineered to address these needs effectively. As one of the trusted battery assembly line manufacturers, we integrate our assembly machines with advanced technologies to ensure seamless production flow and optimal efficiency.

The Role of Lithium Battery Welding Machines in Efficient Assembly Lines

- Ourlithium battery welding machine systems play a crucial role in enhancing the efficiency of lithium battery assembly lines.

- These machines are designed to deliver precise and reliable welds, minimizing rework and ensuring consistent quality.

- By integrating lithium battery welding machinetechnology with our lithium ion battery assembly machine systems, we create a synchronized production process.

- The automated welding stations reduce manual intervention, speed up cycle times, and improve overall throughput.

- This integration allows manufacturers to achieve higher production volumes while maintaining strict quality standards.

Advanced Features of Lithium Ion Battery Assembly Machines for Efficiency

- Xingtai Shuoding Trading Co., Ltd.’s lithium ion battery assembly machineis equipped with advanced features to drive production efficiency.

- The machines feature high-speed robotic arms for precise cell handling and placement, reducing the time needed for each assembly step.

- Intelligent vision systems ensure accurate component alignment, eliminating errors that could slow down production.

- Additionally, our assembly machines have modular structures, allowing easy reconfiguration to accommodate different battery types or production requirements.

- These features, combined with intuitive control interfaces, enable operators to maximize productivity with minimal training.

Lithium Ion Battery Assembly Machine FAQS

How does the lithium ion battery assembly machine improve production speed?

Xingtai Shuoding Trading Co., Ltd.’s lithium ion battery assembly machine improves production speed through advanced automation and optimized workflows. The machines feature high-speed robotic components that can handle and assemble battery cells at rapid rates. Automated material handling systems ensure a continuous supply of components, eliminating delays. The integration of lithium battery welding machine systems within the assembly line further speeds up the process by automating the welding stage, allowing for a seamless and efficient production flow from start to finish.

Can the lithium battery welding machine be integrated into existing assembly lines?

Yes, our lithium battery welding machine is designed for easy integration into existing assembly lines. As experienced battery assembly line manufacturers, we offer flexible welding solutions that can be adapted to various production setups. Our team assesses the existing line’s requirements and designs a welding module that fits seamlessly, whether it’s a standalone welding station or a fully integrated system. This integration allows manufacturers to upgrade their production lines without a complete overhaul, enhancing efficiency while minimizing disruption.

What maintenance is required to keep the lithium ion battery assembly machine efficient?

Maintaining the efficiency of our lithium ion battery assembly machine is straightforward. Regular cleaning of components to remove debris and dust is essential to prevent malfunctions. Periodic lubrication of moving parts ensures smooth operation and reduces wear. Our machines also feature diagnostic systems that alert operators to potential issues, allowing for proactive maintenance. As battery assembly line manufacturers, we provide comprehensive maintenance guidelines and offer technical support to ensure that the assembly machines and lithium battery welding machine systems continue to operate at peak efficiency.

How do customized assembly lines from battery assembly line manufacturers enhance efficiency?

Customized assembly lines from Xingtai Shuoding Trading Co., Ltd. enhance efficiency by aligning perfectly with a manufacturer’s specific production needs. We analyze the production process, product specifications, and output goals to design a line that minimizes bottlenecks. Custom features such as specialized handling systems for unique battery types or integrated quality control checkpoints ensure that every step is optimized. This tailored approach allows manufacturers to achieve higher production rates with fewer errors, making the assembly line more efficient and cost-effective.

Are there safety features included in the lithium ion battery assembly machine?

Yes, safety is a priority in our lithium ion battery assembly machine systems. Our machines include emergency stop mechanisms, safety interlocks, and protective enclosures to prevent accidents. Sensors monitor the production process to detect anomalies and automatically adjust or stop operations if a safety issue is identified. As responsible battery assembly line manufacturers, we ensure that all our equipment meets international safety standards, providing a secure working environment for operators while maintaining high production efficiency.

බෙදාගන්න

-

Lithium Battery Welding Machine | High-Precision, Fast, Safeපුවත්Nov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-Noiseපුවත්Nov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping Supplyපුවත්Nov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & Preciseපුවත්Nov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, Versatileපුවත්Nov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-Speedපුවත්Nov.10,2025