French Door Rubber Seal: Weatherproof, Energy-Saving, Durable.

Understanding Advanced Sealing Solutions for Architectural & Industrial Applications

In modern construction and industrial environments, the integrity of sealing solutions is paramount for operational efficiency, energy conservation, and safety. A critical component in various architectural and specialized door systems is the french door rubber seal, a precision-engineered component designed to provide superior insulation against air, water, dust, and noise. These seals are not merely passive elements but active contributors to a building's thermal performance, acoustic comfort, and long-term structural resilience. From residential French doors requiring enhanced energy efficiency to heavy-duty industrial applications demanding robust environmental protection, the selection and implementation of the correct rubber seal are crucial.

This article delves into the technical intricacies, manufacturing processes, application versatility, and key advantages of high-performance rubber seals, with a particular focus on the innovative E type sealing strip. We will explore industry trends driving demand, detailed technical specifications, diverse application scenarios, and the critical factors that underpin reliable sealing performance.

Industry Trends and Market Dynamics for Advanced Sealing Components

The global market for sealing solutions is experiencing sustained growth, driven by increasing regulatory pressures for energy efficiency, stringent environmental standards, and the escalating demand for durable, low-maintenance building materials. Key trends include:

- Sustainable Materials: A shift towards eco-friendly and recyclable materials for seals, balancing performance with environmental responsibility.

- Enhanced Performance: Demand for seals with extended service life, superior UV resistance, extreme temperature tolerance, and improved compression set resistance.

- Smart Building Integration: Future integration of sensors within sealing systems to monitor performance, detect leaks, and provide predictive maintenance data.

- Customization: Growing need for tailor-made solutions to meet specific aesthetic and functional requirements of complex architectural designs and specialized industrial doors, such as those requiring a robust french door rubber seal bottom or specialized glazing rubber seal strip.

- Digital Prototyping: Utilization of advanced simulation and 3D printing for rapid prototyping and testing of seal designs, optimizing performance before mass production.

These trends highlight a market moving towards more sophisticated, application-specific, and sustainable sealing technologies, where the performance of a french door rubber seal is critical to meeting modern construction and industrial demands.

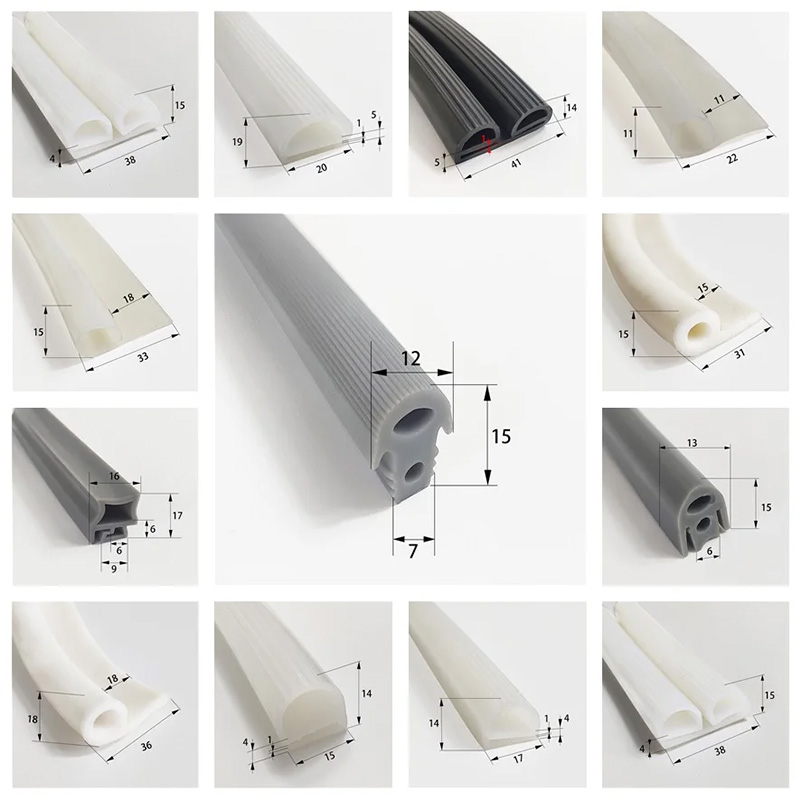

Fig 1: Specialized E type sealing strip for advanced sealing requirements.

Technical Specifications and Material Excellence of E Type Sealing Strips

The E type sealing strip, a prime example of advanced sealing technology, is engineered to deliver exceptional performance across a spectrum of demanding applications. Its unique profile and material composition are crucial for creating an effective barrier.

Core Materials and Properties:

- EPDM (Ethylene Propylene Diene Monomer): Widely used for its excellent resistance to ozone, UV radiation, weathering, and aging. EPDM maintains flexibility at low temperatures and performs well in high-temperature environments, making it ideal for outdoor applications and providing a long service life for a french door rubber seal.

- Silicone Rubber: Offers superior temperature resistance (both high and low extremes), excellent flexibility, and chemical inertness. It is often chosen for applications requiring hygiene (e.g., food processing, medical) or extreme thermal stability.

- PVC (Polyvinyl Chloride): Used for specific profiles due to its good weather resistance and cost-effectiveness, although typically not for the most extreme conditions.

- TPE (Thermoplastic Elastomer): Provides good flexibility, durability, and can be easily colored, offering design versatility.

Key Technical Parameters:

| Parameter | Specification | Testing Standard |

|---|---|---|

| Material Hardness | 60-70 Shore A | ASTM D2240 |

| Tensile Strength | ≥ 8 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Compression Set (70°C, 22h) | ≤ 25% | ASTM D395B |

| Operating Temperature Range | -40°C to +120°C | Internal Testing |

| Ozone Resistance | Excellent (No cracking after 100h, 50pphm) | ASTM D1149 |

| Water Absorption (70°C, 24h) | ≤ 5% | ASTM D570 |

These specifications ensure that the E type sealing strip provides a long-lasting, reliable seal, contributing to reduced energy consumption and improved indoor environmental quality.

Fig 2: Cross-sectional view illustrating the E type sealing strip's design for optimal compression.

Manufacturing Process Flow of High-Performance Rubber Seals

The production of a high-quality french door rubber seal, such as the E type sealing strip, involves a meticulous, multi-stage manufacturing process designed to ensure material integrity, dimensional accuracy, and consistent performance. This process typically utilizes extrusion or compression molding techniques, adhering to stringent quality control standards like ISO 9001 and often specialized certifications for target industries.

Schematic Process Steps:

1. Material Selection & Compounding

Precise selection of raw polymers (EPDM, Silicone, etc.), reinforcing fillers, curatives, and additives. These are meticulously blended in internal mixers to create a homogeneous compound with desired properties (e.g., specific hardness, color, UV resistance).

2. Extrusion / Molding

Extrusion: Compounded material is fed into an extruder, heated, and forced through a die to create the continuous E-profile. This is suitable for long, uniform seals.

Molding: For complex shapes or short runs, compression or injection molding may be used, where material is pressed into a mold cavity.

3. Curing / Vulcanization

The extruded or molded profile undergoes a curing (vulcanization) process, typically in a hot air oven, salt bath, or microwave system. This cross-links the polymer chains, transforming the material from a plastic state to a durable, elastic rubber, significantly enhancing its physical properties and resilience.

4. Finishing & Cutting

Post-curing, the continuous profile is cooled, cut to specified lengths, and may undergo secondary processes like corner molding, splicing, or adhesive application to create a complete sealing system for specific door types, including a specialized french door rubber seal bottom.

5. Quality Control & Testing

Rigorous testing is performed at various stages:

- ‣ Dimensional checks (calipers, laser scanners)

- ‣ Material property tests (hardness, tensile strength, compression set, specific gravity) per ASTM/ISO standards.

- ‣ Environmental aging tests (UV, ozone, temperature cycling).

- ‣ Functional testing (sealing efficiency, acoustic performance).

This controlled manufacturing environment ensures that each french door rubber seal meets the highest standards of quality and performance, contributing to a typical service life exceeding 10-15 years under normal conditions, depending on the material and application specifics.

Fig 3: Quality control inspection of extruded rubber profiles for dimensional accuracy.

Versatile Application Scenarios Across Diverse Industries

The adaptability and robust performance of advanced rubber seals extend their utility far beyond conventional applications. The E type sealing strip, due to its optimized design and material properties, finds critical roles in various sectors:

Target Industries:

- Architectural & Construction: Essential for sealing windows, doors, and curtain walls in commercial and residential buildings. This includes the primary use as a french door rubber seal, ensuring thermal insulation, acoustic dampening, and weather protection. Also crucial for glazing rubber seal strip applications in storefronts and large glass installations.

- Automotive & Transportation: Used in vehicle doors, trunks, and windows for noise reduction, weather sealing, and vibration dampening. Specialized seals are also found in recreational vehicles and trailers, such as a high-performance horse trailer rubber door seal, protecting against dust, water, and varying temperatures during transit.

- Industrial & Manufacturing: Applied in machine enclosures, control cabinets, and access panels to protect sensitive electronics and machinery from dust, moisture, and chemical exposure. This segment also includes robust solutions like hangar door rubber seals and other heavy duty rubber door seals for large industrial openings, where extreme durability and resistance to harsh environments are non-negotiable.

- Marine: Sealing hatches, doors, and portholes on boats and ships, requiring excellent resistance to saltwater, UV, and extreme weather.

- HVAC Systems: Used in air handling units and ductwork to prevent air leakage and improve energy efficiency.

- Petrochemical & Water Supply & Drainage: Specialized chemical-resistant seals are vital in these sectors for process equipment and pipelines, preventing leaks and ensuring environmental safety.

Advantages in Typical Application Scenarios:

- Energy Saving: By preventing air infiltration and exfiltration, E type seals significantly reduce heating and cooling costs in buildings. For instance, a well-sealed French door can reduce air leakage by up to 15-20%, directly impacting HVAC load.

- Corrosion Resistance: EPDM and silicone materials offer excellent resistance to harsh chemicals, acids, alkalis, and ozone, ensuring longevity in industrial and outdoor environments where metal components might corrode.

- Acoustic Insulation: The dense and flexible structure of the seal provides superior sound dampening, creating quieter interior spaces, particularly important for residential applications and offices.

- Weather Protection: Unmatched resistance to rain, snow, wind, and UV radiation, maintaining sealing integrity through extreme weather cycles.

- Dust and Pest Control: Forms a tight barrier preventing ingress of dust, dirt, and pests, maintaining cleanliness and hygiene.

Technical Advantages and Performance Excellence

The design and material science behind the E type french door rubber seal contribute to a suite of technical advantages that set it apart in the market:

- Optimized Compression Profile: The 'E' shape is engineered to provide an optimal balance of compression and rebound, ensuring a consistent seal over time without excessive force required to close the door. This design accommodates minor variations in door/frame tolerances.

- Low Compression Set: High-quality EPDM or silicone exhibits a low compression set, meaning it retains its original shape and sealing capability even after prolonged compression. This is critical for long-term sealing performance and preventing air gaps.

- Exceptional Durability: With superior resistance to abrasion, tearing, and flexing fatigue, these seals withstand millions of door cycles without degradation. This directly translates to reduced maintenance costs and extended operational life.

- Wide Temperature Range Stability: Maintains elasticity and sealing efficacy across extreme temperatures, from sub-zero winters to scorching summers, preventing hardening or softening that could compromise the seal.

- Chemical Inertness: Resistant to many common cleaning agents, mild acids, and alkalis, ensuring the seal's integrity is not compromised by routine maintenance or exposure to industrial environments.

- UV and Ozone Resistance: Crucial for outdoor and sun-exposed applications, preventing material degradation (cracking, hardening) caused by UV radiation and atmospheric ozone.

- Ease of Installation: Designed for efficient installation, often featuring integrated adhesive backing or specific channel-fitting designs, reducing labor time and complexity.

Fig 4: Illustration of EPDM rubber's resilience under various environmental stressors.

Vendor Comparison and Customized Solutions

Selecting the right supplier for critical sealing components like the E type french door rubber seal involves evaluating more than just price. Factors such as manufacturing expertise, material quality, certification, and customization capabilities are paramount.

Key Differentiators in Vendor Selection:

| Criterion | Standard/Premium Vendor | Commodity Vendor |

|---|---|---|

| Material Quality & Consistency | Uses virgin polymers, rigorous QA, traceable batches, ISO/ASTM compliance. | May use recycled content, less stringent QA, inconsistent material properties. |

| Manufacturing Process Control | Advanced extrusion/molding, precise curing, tight dimensional tolerances (e.g., +/- 0.2mm). | Basic processes, wider tolerances (e.g., +/- 0.5mm), potential for defects. |

| Certifications & Compliance | ISO 9001, RoHS, REACH, sometimes industry-specific (e.g., UL, FDA for specific applications). | Minimal or no formal certifications. |

| R&D & Customization | In-house R&D, design assistance, custom tooling, rapid prototyping for bespoke solutions. | Limited customization, only standard profiles. |

| Technical Support & Expertise | Experienced engineers, application-specific advice, post-sales support, long-term partnerships. | Basic transactional support, limited technical depth. |

Tailored Customized Solutions:

Recognizing that every project presents unique challenges, leading manufacturers offer extensive customization capabilities for their sealing strips. This can include:

- Custom Profiles: Designing entirely new cross-sectional shapes to perfectly fit unconventional door frames or specialized industrial enclosures. This is crucial for applications demanding a unique heavy duty rubber door seal profile.

- Material Blends: Developing specific rubber compounds to meet unique performance requirements, such as enhanced chemical resistance, flame retardancy, or ultra-low temperature flexibility.

- Color Matching: Producing seals in specific colors to match architectural aesthetics or comply with safety coding.

- Integrated Components: Incorporating metal inserts, fabric reinforcements, or adhesive backing during the extrusion process for enhanced functionality or ease of installation.

- Precision Cutting & Splicing: Providing seals cut to exact lengths, with mitered corners or custom-molded frames for seamless integration, particularly for complex French door systems.

These customized solutions ensure optimal performance and integration, delivering significant long-term value and project success.

Fig 5: Various custom rubber seal profiles demonstrating manufacturing versatility.

Application Case Studies & Customer Experience

Real-world applications demonstrate the tangible benefits of high-quality sealing solutions. Our E type sealing strips have been deployed in numerous demanding projects, showcasing their reliability and effectiveness.

Case Study 1: High-Performance Residential Development

- Challenge: A luxury residential complex in a cold climate required French doors with superior thermal insulation and acoustic performance to meet stringent energy codes and occupant comfort expectations. Standard seals were failing to meet the U-factor and STC ratings.

- Solution: Customized EPDM E type french door rubber seal profiles were developed with an enhanced multi-chamber design. The seals were installed on over 300 French doors and windows throughout the complex.

- Outcome: Post-installation blower door tests showed a 25% reduction in air infiltration compared to initial designs. Acoustic measurements confirmed a 5dB improvement in sound reduction, significantly enhancing occupant satisfaction. The client reported a noticeable decrease in energy consumption during the first winter season, affirming the long-term ROI.

Case Study 2: Industrial Hangar Door Upgrade

- Challenge: A large aircraft hangar required an upgrade to its enormous sliding doors. Existing seals were degraded by extreme weather exposure (high winds, heavy rain, UV) and frequent operation, leading to significant energy loss and internal dust accumulation. A heavy-duty, long-lasting hangar door rubber seal was needed.

- Solution: A custom, heavy-duty EPDM profile, designed for large gap filling and extreme compression, was manufactured. This solution specifically addressed the need for robust heavy duty rubber door seals capable of withstanding industrial stresses.

- Outcome: The new seals provided a weather-tight and dust-proof enclosure. Energy audits showed a 10-12% reduction in heating costs for the hangar. The robust design has shown no signs of degradation after five years of continuous operation in harsh conditions, far exceeding the lifespan of previous seals.

Customer Feedback:

"The E type sealing strips were a game-changer for our new office complex. We achieved excellent thermal performance and a noticeable reduction in external noise, contributing directly to a more productive work environment. The customization support was invaluable."

Frequently Asked Questions (FAQ)

Q: What is the expected service life of your E type french door rubber seal?

A: Our EPDM and silicone E type sealing strips are designed for a service life of 10-15 years, and often longer, under normal operating conditions. This is supported by accelerated aging tests and real-world performance data.

Q: Can these seals be used in extreme temperatures?

A: Yes, EPDM compounds offer a working temperature range of -40°C to +120°C, while silicone can withstand even greater extremes, typically from -60°C to +200°C, making them suitable for most challenging environments.

Q: Are your seals resistant to UV and ozone?

A: Absolutely. EPDM, in particular, is renowned for its excellent resistance to UV radiation and ozone, making our seals ideal for outdoor and sun-exposed applications without degradation.

Q: Do you offer custom profiles or colors?

A: Yes, we specialize in customized solutions. We can develop unique profiles and custom color matches to meet specific aesthetic or functional project requirements. Our engineering team can assist from design to production.

Q: What are your lead times for orders?

A: Standard profiles typically have a lead time of 2-4 weeks, depending on order volume and current production schedule. Custom orders may require 6-8 weeks for tooling and initial production. Please contact our sales team for precise lead time estimates for your specific requirements.

Commitment to Quality: Warranty & Customer Support

Our commitment extends beyond delivering high-performance sealing solutions. We stand behind the quality and durability of our E type sealing strips with comprehensive warranty and dedicated customer support.

Warranty Commitment:

We offer a standard 5-year limited warranty on all EPDM and silicone E type sealing strips against manufacturing defects and premature material degradation under normal use and recommended installation procedures. This warranty underscores our confidence in the quality of our manufacturing processes and the resilience of our materials. Extended warranty options may be available for specific project scales or custom applications.

Dedicated Customer Support:

Our B2B clients benefit from an experienced and responsive customer support team. From initial consultation and technical specifications to post-installation assistance, we provide end-to-end support:

- Technical Consultation: Expert advice on material selection, profile design, and application-specific challenges.

- Order Fulfillment: Efficient processing of orders, clear communication on lead times, and reliable logistics to ensure on-time delivery.

- After-Sales Support: Assistance with installation queries, troubleshooting, and handling any warranty-related concerns promptly and professionally.

- Documentation: Provision of comprehensive product data sheets, material safety data sheets (MSDS), and compliance certificates (e.g., ISO, ASTM test reports).

We are committed to building long-term partnerships based on trust, quality, and exceptional service.

Conclusion

The E type sealing strip represents the pinnacle of modern sealing technology, offering unparalleled performance, durability, and versatility. As a critical component, the french door rubber seal plays a pivotal role in enhancing energy efficiency, ensuring environmental protection, and delivering long-term value across a multitude of industries. By leveraging advanced materials, precise manufacturing processes, and a commitment to continuous innovation, these seals meet and exceed the rigorous demands of today's architectural and industrial landscapes. Investing in high-quality, expertly engineered sealing solutions is not just a choice for performance but a strategic decision for sustainability and operational excellence.

References

- ASTM International. (n.d.). Standard Test Methods for Rubber Property—Tear Resistance (Angle Tear Test). Retrieved from astm.org

- ISO (International Organization for Standardization). (n.d.). ISO 9001: Quality management systems – Requirements. Retrieved from iso.org

- Rubber Manufacturers Association. (n.d.). Rubber Handbook: Properties of Elastomers. Retrieved from rma.org

- U.S. Department of Energy. (n.d.). Energy-Efficient Windows & Doors. Retrieved from energy.gov

- Sealing Technology Magazine. (Various Issues). Advances in Elastomer Technology for Sealing Applications.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025