Essential Guide to Flexible and Soft Rubber Sealing Strips

A pa'u fa'amau fa'amau is a versatile and vital component used in a variety of industries to ensure tight seals and prevent leakage of gases, liquids, or dust. Whether it’s used in automotive, construction, or appliance industries, rubber sealing strips play a critical role in enhancing performance, durability, and energy efficiency. In this article, we will explore the different types of rubber sealing strips, including flexible rubber sealing strips and soft rubber sealing strips, their applications, and how to choose the right product for your needs.

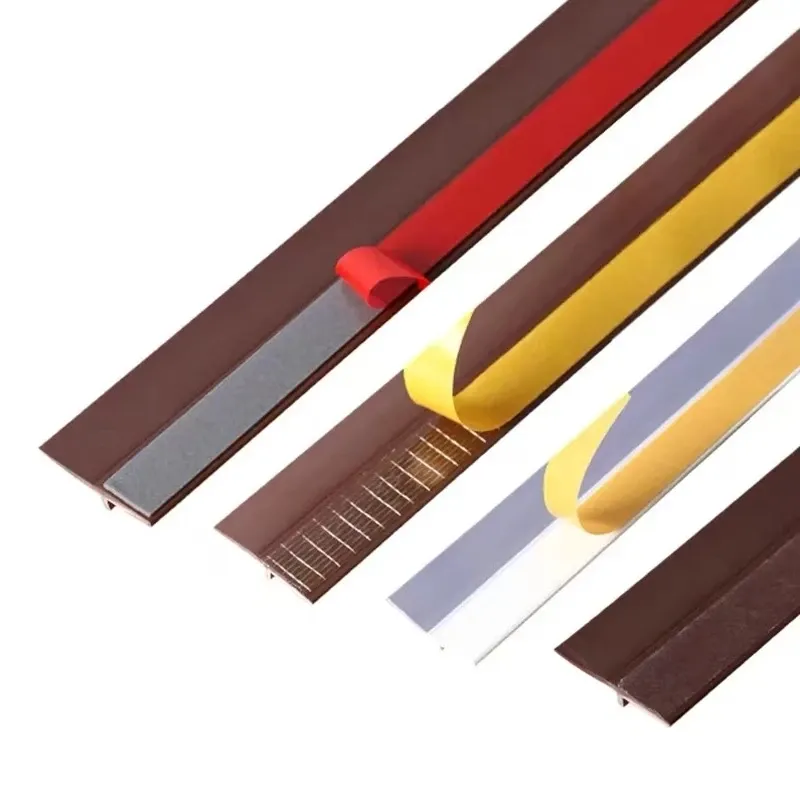

What is a Rubber Sealing Strip?

A pa'u fa'amau fa'amau is a flexible, rubber-based material used to create seals around doors, windows, machinery, and other equipment. The strip’s primary function is to prevent the unwanted entry of air, water, dust, or sound while ensuring that the enclosed environment remains sealed. Rubber sealing strips can be manufactured from various types of rubber, including EPDM (ethylene propylene diene monomer), neoprene, silicone, and nitrile, each offering distinct properties such as resistance to temperature, chemicals, and UV rays.

These sealing strips come in various forms, such as solid, hollow, and sponge types, depending on the application and required flexibility. They are also available in a range of sizes and profiles, making them adaptable to different sealing needs.

Types of Rubber Sealing Strips

Flexible Rubber Sealing Strips:

- Description: Flexible rubber sealing strips are made from highly elastic rubber materials, which allow them to bend and adapt to various surfaces and gaps. These strips are commonly used in environments where high flexibility is required, and they can provide a secure seal without compromising on movement or flexibility.

- Applications: Flexible rubber sealing strips are ideal for doors, windows, and automotive parts that require adaptability. These strips are widely used in areas with shifting or changing dimensions, such as around hatchbacks, sliding doors, and movable windows.

- Advantages:

- High elasticity and adaptability.

- Excellent resistance to weathering, ozone, and UV rays.

- Provides strong insulation against dust, water, and noise.

Soft Rubber Sealing Strips:

- Description: Soft rubber sealing stripsare made from softer and more pliable rubber compounds. These strips are used when a softer, gentler seal is required, often to prevent surface damage or where there is a need for a more cushion-like seal.

- Applications: Soft rubber sealing strips are used in applications where you need to prevent contact damage or where there is a need to protect delicate surfaces. They are commonly found in appliances, automotive door seals, or as weather stripping around windows and doors.

- Advantages:

- Softer and more pliable for gentle sealing.

- Provides excellent noise reduction and thermal insulation.

- Ideal for sealing delicate or sensitive surfaces without causing damage.

Sponge Rubber Sealing Strips:

- Description: Sponge rubber sealing strips contain air pockets within the rubber, giving them a spongy texture. This type of seal is perfect for applications requiring compression and flexibility.

- Applications: Sponge rubber sealing strips are used in machinery, electrical enclosures, and doors that require a flexible, compressible seal to prevent dust, air, and water ingress.

- Advantages:

- Provides an excellent cushion and compression resistance.

- Great for irregular gaps and surfaces.

- Good for sealing high-pressure environments.

Solid Rubber Sealing Strips:

- Description: Solid rubber sealing strips are made from solid rubber without air pockets, providing a dense, durable, and strong seal. These strips are used when a tight and robust seal is required.

- Applications: Solid rubber seals are used in heavy-duty applications, such as industrial machinery, equipment, and doors exposed to harsh weather conditions or extreme pressure.

- Advantages:

- Provides a strong, tight seal.

- Highly durable and resistant to wear and tear.

- Ideal for high-stress applications.

Materials Used in Rubber Sealing Strips

The performance of a pa'u fa'amau fa'amau is largely determined by the type of rubber used in its manufacturing. Different types of rubber have unique properties that make them suitable for various applications. Below are some commonly used materials for rubber sealing strips:

EPDM (Ethylene Propylene Diene Monomer):

- Meatotino: EPDM is highly resistant to weathering, UV radiation, ozone, and extreme temperatures. It also performs well in outdoor and automotive applications.

- Applications: Frequently used for weatherstripping in cars, buildings, and windows.

Neoprene:

- Meatotino: Neoprene is known for its excellent resistance to oils, chemicals, and water, making it ideal for industrial and marine environments.

- Applications: Commonly used in industrial sealing, plumbing, and automotive applications.

Silicone Rubber:

- Meatotino: Silicone is known for its high-temperature resistance and durability. It remains flexible at both high and low temperatures, making it ideal for sealing applications in extreme conditions.

- Applications: Commonly used in food-grade sealing, medical devices, and high-temperature industrial applications.

Nitrile Rubber:

- Meatotino: Nitrile rubber is highly resistant to oils, fuels, and solvents, making it ideal for automotive and machinery applications.

- Applications: Often used for seals in automotive engines, fuel systems, and hydraulic equipment.

Polyurethane Rubber:

- Meatotino: Polyurethane rubber offers superior wear resistance and is highly durable under mechanical stress.

- Applications: Used in automotive and heavy machinery seals that require long-lasting durability.

Benefits of Using Rubber Sealing Strips

Enhanced Insulation: Rubber sealing strips offer superior thermal insulation, helping to maintain temperature control in buildings, refrigeration units, and automotive applications.

Noise Reduction: Rubber sealing strips can significantly reduce noise levels, making them ideal for use in windows, doors, and machinery.

Water and Dust Protection: One of the primary functions of rubber sealing strips is to protect against the intrusion of water, dust, and air, preventing damage to equipment and creating more energy-efficient systems.

Flexibility: Rubber sealing strips are flexible, allowing them to conform to irregular surfaces, making them versatile for various sealing needs.

Durability: Rubber is known for its resilience and long-lasting performance, making sealing strips durable and cost-effective over time.

Applications of Rubber Sealing Strips

Automotive Industry: Rubber sealing strips are widely used in cars, trucks, and buses to seal doors, windows, sunroofs, and trunks. These seals help prevent water leakage, reduce noise, and improve overall insulation.

Construction: Rubber sealing strips are used in doors, windows, and roofs in the construction industry. They provide a barrier against drafts, water leaks, and noise, helping to improve energy efficiency.

Appliances: Rubber sealing strips are found in household appliances, such as refrigerators, dishwashers, and washing machines, to ensure energy efficiency and prevent leaks.

Industrial Equipment: Rubber seals are used in machinery, equipment, and enclosures to keep out dust, moisture, and other contaminants, ensuring proper function and longevity.

Marine Industry: Sealing strips are used to prevent water leakage in boats, ships, and marine containers. They help keep the interiors dry and secure.

Electronics: Rubber sealing strips are used in electronic enclosures to prevent dust and moisture from damaging sensitive components.

How to Choose the Right Rubber Sealing Strip

When choosing a pa'u fa'amau fa'amau, consider the following factors:

Mea: Choose a material based on the specific requirements of your application, such as resistance to chemicals, weather, temperature, or moisture.

Profile and Size: The size and shape of the sealing strip must fit the gap or space it is intended to seal. Measure the dimensions carefully before purchasing.

Durability: Consider the operating conditions (temperature range, pressure, and exposure to chemicals) to determine the required durability of the rubber seal.

Compression: Make sure the rubber sealing strip can compress to form a tight seal without losing flexibility or performance.

Customization: Some applications may require custom rubber seals. Look for manufacturers that offer customizable sealing strips to suit your specific needs.

Rubber sealing strips are indispensable in many industries due to their flexibility, durability, and efficiency in preventing leaks, dust, water, and noise. Whether you need a flexible rubber sealing strip for a movable component or a soft rubber sealing strip for delicate surfaces, there’s a sealing solution for every need. By understanding the various types of rubber sealing strips, their applications, and how to choose the right material, you can ensure a more efficient and long-lasting sealing solution for your specific requirements.

Faasoa

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeTala FouNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseTala FouNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyTala FouNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseTala FouNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileTala FouNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedTala FouNov.10,2025