Lithium Cell Machinery: High-Speed, Precise, Turnkey Lines

Lithium Cell Machinery is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of specialized electronic and electrical machinery equipment. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Lithium Cell Machinery Overview

- Benefits & Use Cases of Lithium Cell Machinery in Manufacturing of specialized electronic and electrical machinery equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Lithium Cell Machinery from XINGTAI SHUODING TRADING CO.,LTD

Lithium Cell Machinery Overview

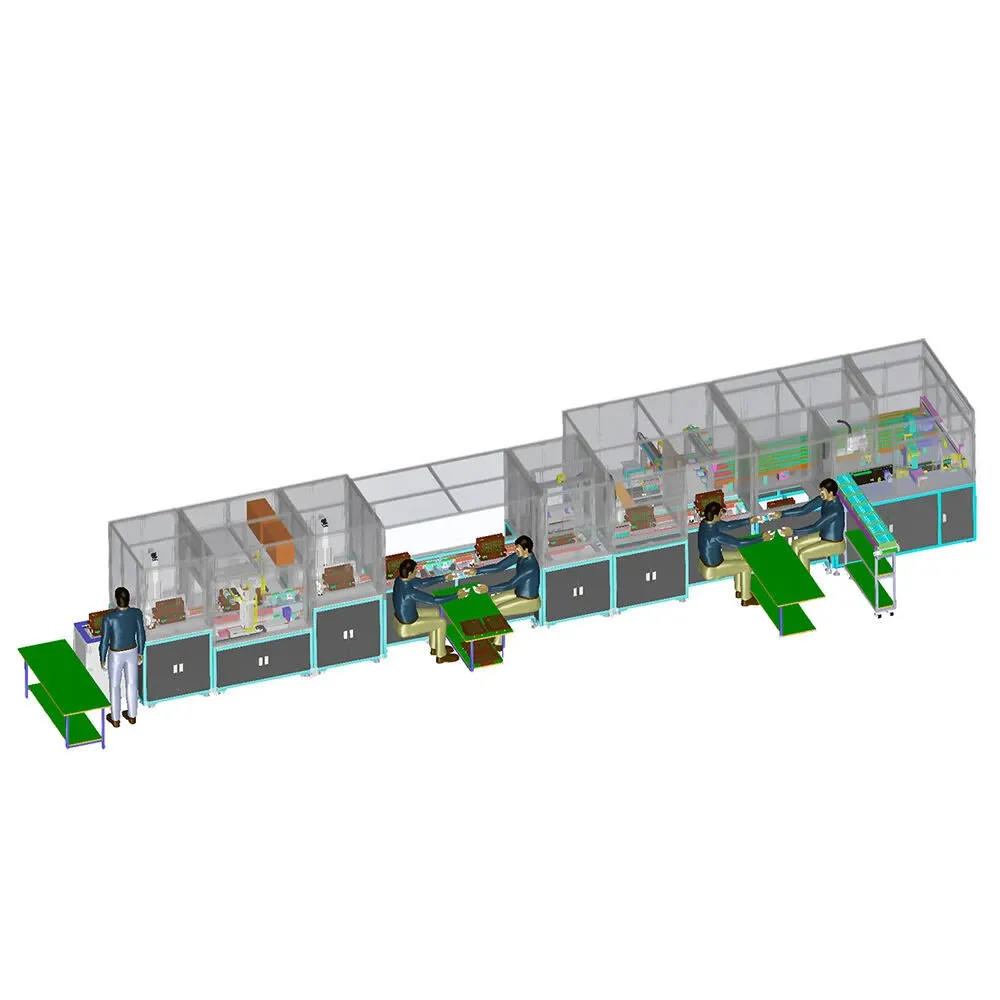

Lithium Cell Machinery refers to the integrated automation, testing, and handling systems that assemble and validate lithium-ion cells, modules, and battery packs. In the Special Equipment Manufacturing Industry—especially within Manufacturing of specialized electronic and electrical machinery equipment—these systems underpin high-volume, high-yield production. Typical stations across a lithium ion battery assembly line include cell sorting and grading, precision tab and busbar laser welding, module stacking, pack assembly, BMS integration, end-of-line functional testing, and full traceability through an MES. When paired with machine vision and robotics, a modern lithium ion battery assembly machine delivers consistent quality while protecting sensitive components from ESD and contamination.

XINGTAI SHUODING TRADING CO.,LTD provides lithium ion battery production equipment designed for demanding 24/7 environments. Systems are modular to scale from pilot lines to fully automated pack lines and can integrate with ERP/MES via common industrial protocols. Precision fixturing, CCD alignment, and closed-loop process control help maintain dimensional accuracy and weld integrity. For B2B decision makers evaluating battery assembly line manufacturers, the ability to tailor recipe-driven processes, enforce quality gates, and simplify changeovers is essential—and these are core strengths of XINGTAI SHUODING’s engineering approach.

Benefits & Use Cases of Lithium Cell Machinery in Manufacturing of specialized electronic and electrical machinery equipment

Across e-mobility, stationary ESS, power tools, and industrial electronics, Lithium Cell Machinery enables repeatable assembly with high throughput and robust compliance. A typical lithium ion battery assembly line combines automated material handling with safety-critical checks: IR and insulation tests, DCIR measurement, leak and pressure tests, and pack-level end-of-line validation. For manufacturers producing multiple chemistries or formats (cylindrical, prismatic, pouch), recipe management and quick-change tooling minimize downtime while meeting precise torque, weld, and alignment specifications. Vision-guided robots, servo-driven conveyors, and digital work instructions ensure consistent assembly quality from cell loading to final pack sealing.

XINGTAI SHUODING TRADING CO.,LTD differentiates its lithium ion battery production equipment with modular cells-to-pack architectures, traceability-first software, and maintainability by design. Competitive advantages include laser welding process control, integrated FOD/ESD prevention, barcode/RFID genealogy, and SPC dashboards for real-time decision making. Whether you are scaling a pilot line or standardizing global capacity, partnering with battery assembly line manufacturers that offer lifecycle support—FAT/SAT, documentation, training, and remote diagnostics—reduces risk. XINGTAI SHUODING’s systems are engineered to streamline commissioning, support multi-variant production, and align with quality frameworks common to specialized electronic and electrical machinery equipment.

Cost, Maintenance & User Experience

Total cost of ownership for Lithium Cell Machinery spans beyond the initial CapEx to include OEE, consumables, utilities, changeover time, and serviceability. Designing for maintainability—standardized spare parts, easy-access panels, and clear PM schedules—cuts downtime and safeguards ROI. For many B2B producers, the fastest returns come from higher yield and fewer quality escapes. User-centric HMIs, guided troubleshooting, and recipe-driven setups reduce operator error, while integrated safety (light curtains, interlocks, E-Stop zones) keeps production compliant and predictable. Energy efficiency features—smart vacuum control, air-leak minimization, and servo optimization—further reduce operating costs over the equipment’s lifecycle.

XINGTAI SHUODING TRADING CO.,LTD emphasizes reliability and lifecycle support across its lithium ion battery assembly machine portfolio. Customers in the Special Equipment Manufacturing Industry value factory acceptance testing (FAT), site acceptance testing (SAT), operator and maintenance training, and responsive after-sales service. Condition monitoring options and data logging help plan predictive maintenance and correlate process parameters with quality KPIs. The result is a smoother ramp, fewer unplanned stops, and a clearer path to ROI for lines ranging from prototype to fully automated mass production.

Sustainability & Market Trends in manufacturing

Battery manufacturing is evolving under tighter sustainability targets and regulatory frameworks, including expanding requirements for traceability, responsible sourcing, and end-of-life stewardship. OEMs and Tier suppliers are prioritizing energy-efficient lines, comprehensive genealogy, and data transparency to support carbon footprint reporting and future battery passport initiatives. At the process level, dry-room compatibility, fume capture for laser processes, and solvent-safe materials handling support both safety and environmental goals. As gigafactory investments rise and formats diversify—LFP growth, emerging LMFP and solid-state R&D—flexible automation becomes the strategic hedge against technology shifts and demand volatility.

XINGTAI SHUODING TRADING CO.,LTD positions its Lithium Cell Machinery as forward-looking and eco-conscious. Designs emphasize energy-saving drives, compressed-air optimization, and modular cells-to-pack lines that can be reconfigured rather than replaced. Built-in traceability supports responsible sourcing and quality records, while remote diagnostics can reduce travel-related emissions for service. For manufacturers benchmarking lithium ion battery production equipment, choosing partners that invest in greener operations, recyclable packaging, and long-lived platforms helps align operations with corporate ESG commitments and evolving regulations—without compromising throughput or quality.

Conclusion on Lithium Cell Machinery from XINGTAI SHUODING TRADING CO.,LTD

Lithium Cell Machinery underpins modern, data-driven battery production—connecting precision processes with dependable automation and end-to-end traceability. For organizations in the Special Equipment Manufacturing Industry and Manufacturing of specialized electronic and electrical machinery equipment, XINGTAI SHUODING TRADING CO.,LTD delivers scalable, maintainable solutions that help accelerate time-to-volume while protecting quality and cost targets. If you are evaluating a lithium ion battery assembly line or seeking a trusted battery assembly line manufacturer, partner with a team that understands both technology and operations.

- Contact us: email: sdtrading0927@126.com

- Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025