Manufacturers of High-Quality Dust-Proof Sealing Strips for Various Applications

The Importance of Dust-Proofing Sealing Strips in Modern Manufacturing

In today's fast-paced manufacturing environment, ensuring the integrity and longevity of machinery and products has become a top priority. Among the various components that play a role in this, dust-proofing sealing strips have emerged as a critical factor. These strips are designed to create an effective barrier against dust, dirt, and other contaminants, thereby enhancing the performance and durability of equipment. In this article, we will explore the significance of dust-proofing sealing strips, their manufacturing processes, and the benefits they offer to factories.

Understanding Dust-Proofing Sealing Strips

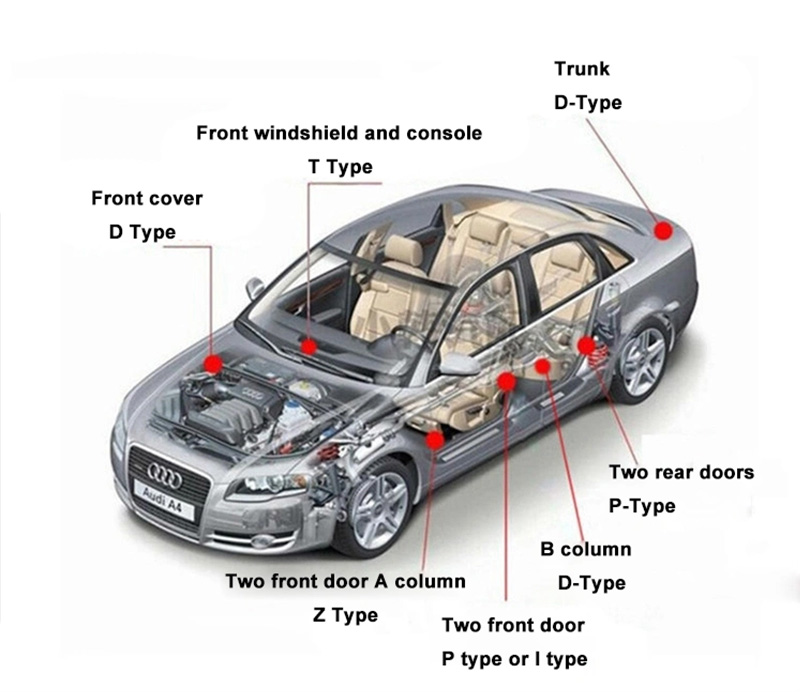

Dust-proofing sealing strips are typically made from flexible materials such as rubber, silicone, or foam. They are specifically engineered to fit snugly around doors, windows, machinery, and various other openings. The primary function of these strips is to seal gaps that could allow dust and debris to infiltrate sensitive areas. By preventing the entry of contaminants, dust-proofing sealing strips help maintain a clean and safe working environment, which is essential for optimal manufacturing processes.

Manufacturing Processes for Sealing Strips

The production of dust-proofing sealing strips involves several key steps. First, manufacturers select high-quality raw materials that are durable and capable of withstanding harsh conditions. Once the materials are chosen, they undergo a compounding process where additives are mixed to enhance properties such as flexibility, resilience, and UV resistance.

Next, the raw materials are molded into strips using various techniques, including extrusion and compression molding. Extrusion involves forcing the heated material through a die to create a continuous strip, while compression molding utilizes molds to shape the material into specific designs. Quality control is critical during this phase, as manufacturers must ensure that the sealing strips meet stringent industry standards and specifications.

dust-proofing sealing strip factories

After molding, the strips are subjected to rigorous testing to evaluate their effectiveness in dust-proofing. This testing often includes assessing the strips' resistance to wear and tear, temperature fluctuations, and exposure to chemicals. Only after passing these tests do the sealing strips go into production for widespread distribution.

Benefits of Dust-Proofing Sealing Strips

The advantages of incorporating dust-proofing sealing strips in manufacturing facilities are manifold. Firstly, these strips significantly reduce the amount of dust and debris that can accumulate inside machinery and production areas. This reduction leads to less frequent maintenance and repairs, thereby saving factories both time and money.

Additionally, a dust-free environment contributes to higher product quality. When dust and contaminants are kept at bay, the risk of defects in the final product decreases. This is particularly crucial in industries such as electronics, pharmaceuticals, and food processing, where cleanliness is paramount.

Moreover, dust-proofing sealing strips also enhance worker safety. By preventing the entry of potentially hazardous particles, factories can create a healthier work environment for their employees. This not only boosts morale but also reduces the likelihood of workplace accidents related to poor visibility or equipment malfunction.

Conclusion

In conclusion, dust-proofing sealing strips are an integral part of modern manufacturing that cannot be overlooked. Their role in protecting machinery, maintaining product quality, and ensuring worker safety is invaluable. As factories continue to seek efficiency and excellence in production, investing in high-quality dust-proofing sealing strips is a step towards achieving those goals. Given their importance, it is vital for manufacturers to partner with reputable suppliers who can deliver durable and effective sealing solutions tailored to their specific needs.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025