jan . 20 , 2025 01:47

Back to list

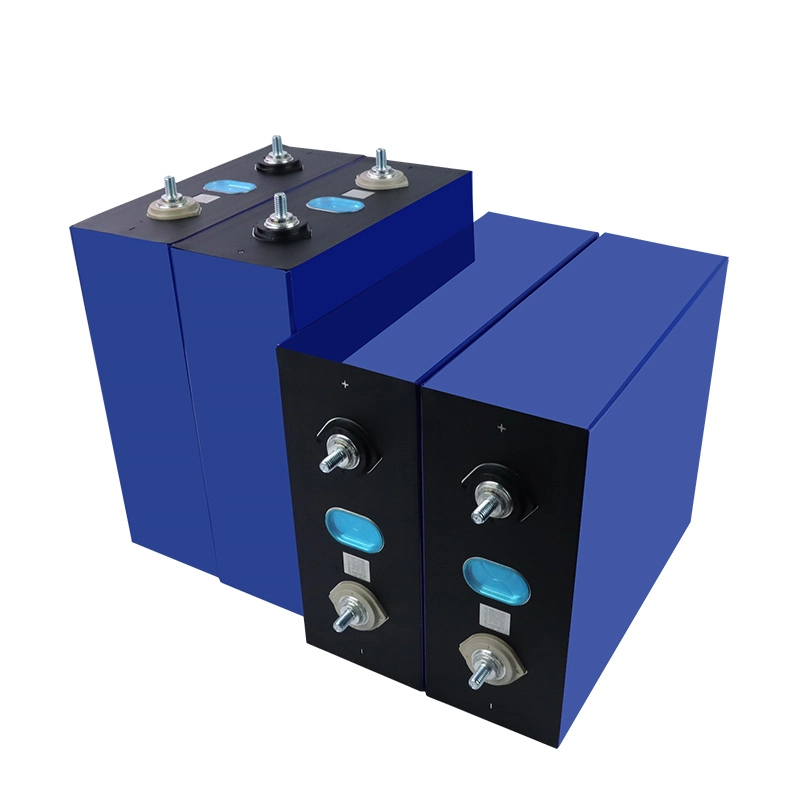

lithium ion battery pack assembly line

An efficient battery assembly line is pivotal to the production of high-performance batteries that power everything from everyday gadgets to electric vehicles and renewable energy storage systems. Establishing such a line involves far more than simply piecing together components; it is an intricate process that requires a blend of advanced technology, skilled labor, and precise quality control to ensure the production of reliable, long-lasting batteries.

Authoritativeness in the industry emerges from both innovation and proven reliability. By fostering partnerships with leading material suppliers, researchers, and technology developers, businesses can remain at the forefront of battery innovations. These collaborations can lead to breakthroughs in energy densities or charging speeds, keeping the company competitive and authoritative in a rapidly evolving market. Trustworthiness, the bedrock of customer loyalty, is reinforced through transparency and commitment to sustainability. Environmentally conscious practices, such as recycling programs for battery materials and reducing carbon footprints, are increasingly important to consumers. Clearly communicating these efforts through certifications and sustainability reports can enhance brand image and customer trust. Moreover, providing warranties and responsive customer service fortifies consumer confidence in the products. In conclusion, excelling in the battery assembly line sector calls for a harmonious blend of technological innovation, skilled labor, quality control, and sustainability efforts. By consistently pushing the boundaries of what is possible and maintaining a steadfast commitment to quality and ethics, companies can not only lead the battery manufacturing market but also contribute meaningfully to a more sustainable future.

Authoritativeness in the industry emerges from both innovation and proven reliability. By fostering partnerships with leading material suppliers, researchers, and technology developers, businesses can remain at the forefront of battery innovations. These collaborations can lead to breakthroughs in energy densities or charging speeds, keeping the company competitive and authoritative in a rapidly evolving market. Trustworthiness, the bedrock of customer loyalty, is reinforced through transparency and commitment to sustainability. Environmentally conscious practices, such as recycling programs for battery materials and reducing carbon footprints, are increasingly important to consumers. Clearly communicating these efforts through certifications and sustainability reports can enhance brand image and customer trust. Moreover, providing warranties and responsive customer service fortifies consumer confidence in the products. In conclusion, excelling in the battery assembly line sector calls for a harmonious blend of technological innovation, skilled labor, quality control, and sustainability efforts. By consistently pushing the boundaries of what is possible and maintaining a steadfast commitment to quality and ethics, companies can not only lead the battery manufacturing market but also contribute meaningfully to a more sustainable future.

Share

Previous:

Latest news

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025