Wholesale Anode Calendering Solutions for Efficient Battery Production and Performance Enhancement

Understanding the Wholesale Anode Calender A Key Component in Battery Production

In the rapidly evolving landscape of energy storage technologies, the demand for efficient and high-quality battery components is at an all-time high. Among these components, the anode plays a crucial role, especially in lithium-ion batteries, which are widely used in electric vehicles, smartphones, and renewable energy storage systems. One vital process in the production of battery anodes is calendering, and understanding the wholesale anode calender is essential for manufacturers looking to enhance their production efficiency and product quality.

What is Calendering?

Calendering is a mechanical process that involves passing materials through a series of rollers to achieve desired thickness, density, and uniformity. In the context of battery production, calendering refers to the process of compacting and shaping the anode material, which is often composed of graphite or other conductive materials. This process not only improves the structural integrity of the anode but also enhances its electrochemical performance.

The Importance of Anode Calendering

1. Uniform Thickness One of the primary goals of anode calendering is to achieve a uniform thickness across the anode sheet. Irregularities in thickness can lead to uneven charge distribution during battery operation, resulting in reduced efficiency and shorter lifespan. A wholesale anode calender ensures that each batch of anodes meets specific thickness parameters, critical for performance consistency.

2. Increased Density The calendering process increases the density of the anode material. Higher density translates to more active material per unit area, which boosts the energy capacity of the battery. Manufacturers are increasingly focusing on optimizing the density of their anodes as battery energy requirements grow.

3. Enhanced Mechanical Properties The calendering process also improves the mechanical properties of the anode. A well-calendared anode exhibits better adhesion to the current collector and increased resistance to cracking and delamination during battery cycling. This is essential for ensuring the longevity and reliability of batteries, especially in high-performance applications.

4. Scalability and Consistency For manufacturers operating on a wholesale level, consistency in production is critical. High-quality calendering equipment ensures that large quantities of anodes can be produced with minimal variation from batch to batch. This scalability is crucial for meeting the demands of large-scale battery production, such as those required for electric vehicles and grid storage.

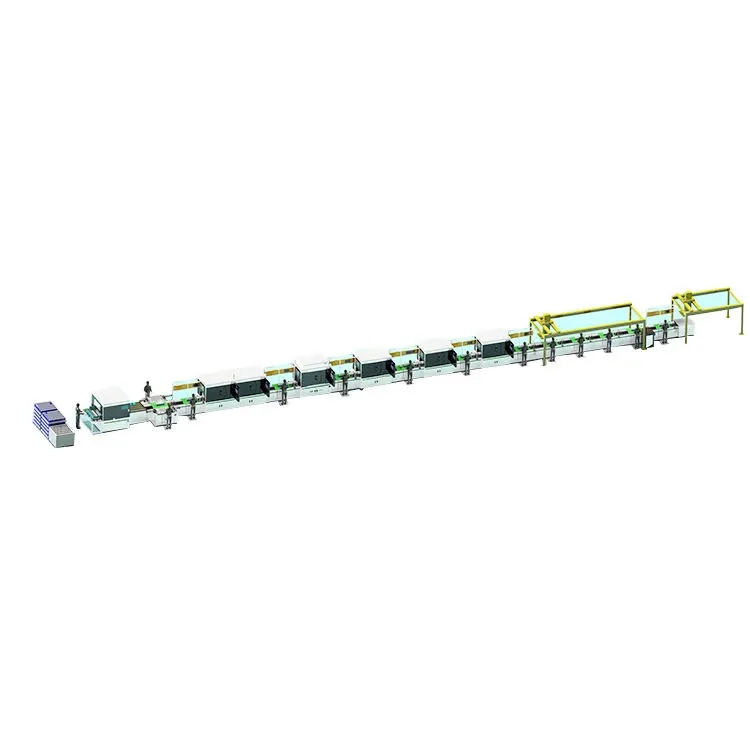

wholesale anode calender

Choosing the Right Wholesale Anode Calender

When selecting a wholesale anode calender, several factors must be considered to ensure that it meets production needs effectively

1. Roller Material and Design The choice of roller material and design can significantly impact the quality of the calendering process. Harder materials resist wear and maintain their shape, while precise designs ensure uniform pressure across the material.

2. Temperature Control Some anode materials may require specific temperature settings during calendering to achieve optimal performance. Advanced calenders incorporate heating elements to facilitate this process, making it crucial for manufacturers to choose equipment that allows for temperature adjustment.

3. Automation Features In today’s manufacturing environment, automation plays a vital role in improving efficiency and reducing labor costs. Anodes with automated calendering systems can improve production rates and minimize human error.

4. Maintenance and Support Investing in a calendering system also requires consideration of ongoing maintenance and technical support. Manufacturers should look for suppliers who offer comprehensive service packages, ensuring that production downtime is minimized.

Conclusion

The wholesale anode calender is a fundamental element in the production of high-quality battery anodes. By understanding the importance of calendering, manufacturers can enhance their product performance and reliability. As the demand for better and more efficient energy storage solutions continues to rise, investing in advanced calendering technology will play a vital role in staying competitive within the market. Through careful selection and implementation of anode calendering processes, manufacturers can ensure that they produce superior anodes that meet the needs of modern energy storage applications.

Share

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025