Expert Cylindrical Cell Manufacturing: Precision & Quality

The Imperative of Advanced cylindrical cell manufacturing

The global energy landscape is undergoing a profound transformation, driven by the escalating demand for high-performance, reliable, and cost-effective energy storage solutions. At the forefront of this revolution are cylindrical lithium-ion cells, renowned for their robust structure, excellent energy density, and proven safety records. The efficacy and competitiveness of these cells are intrinsically linked to the sophistication of their production processes. As a pivotal component in electric vehicles (EVs), renewable energy storage systems (ESS), and advanced portable electronics, the precision and efficiency of cylindrical cell manufacturing are paramount.

Modern battery manufacturing demands a holistic approach, encompassing cutting-edge materials science, sophisticated engineering, and highly automated production lines. Our focus here is to delve into the intricate aspects of this manufacturing domain, highlighting the technical specifications, application advantages, and the crucial role of advanced automation in meeting today's rigorous industry demands for cell types such as 18650, 21700, 26650, and 32650.

Industry Trends Shaping Cylindrical Cell Manufacturing

The battery industry is dynamic, with continuous innovation driving significant trends in cylindrical cell manufacturing. Key trends include:

- Increased Automation and Robotics: To achieve higher throughput, lower labor costs, and enhanced precision, manufacturers are heavily investing in fully automated production lines, integrating advanced robotics for material handling, cell assembly, and quality control.

- Digitalization and Industry 4.0: The adoption of IoT sensors, real-time data analytics, and Artificial Intelligence (AI) for predictive maintenance, process optimization, and yield improvement is becoming standard. This enables a 'smart factory' approach to cylindrical cell manufacturing process.

- Sustainable Manufacturing Practices: Growing environmental concerns are pushing for greener manufacturing, including energy-efficient processes, waste reduction, and solvent recovery systems, alongside efforts for circular economy models through recycling.

- Advanced Materials Integration: Research and development into new electrode materials (e.g., silicon-anode, solid-state electrolytes) and separator technologies are promising higher energy densities, faster charging capabilities, and improved safety profiles for future cylindrical cells.

- Scalability and Modularity: Production lines are designed to be highly scalable and modular, allowing manufacturers to quickly adapt to changing market demands, introduce new cell formats, or expand capacity with minimal disruption.

These trends underscore the importance of flexible, efficient, and technologically advanced production solutions for maintaining a competitive edge in the global battery market.

The Cylindrical Cell Manufacturing Process: A Detailed Overview

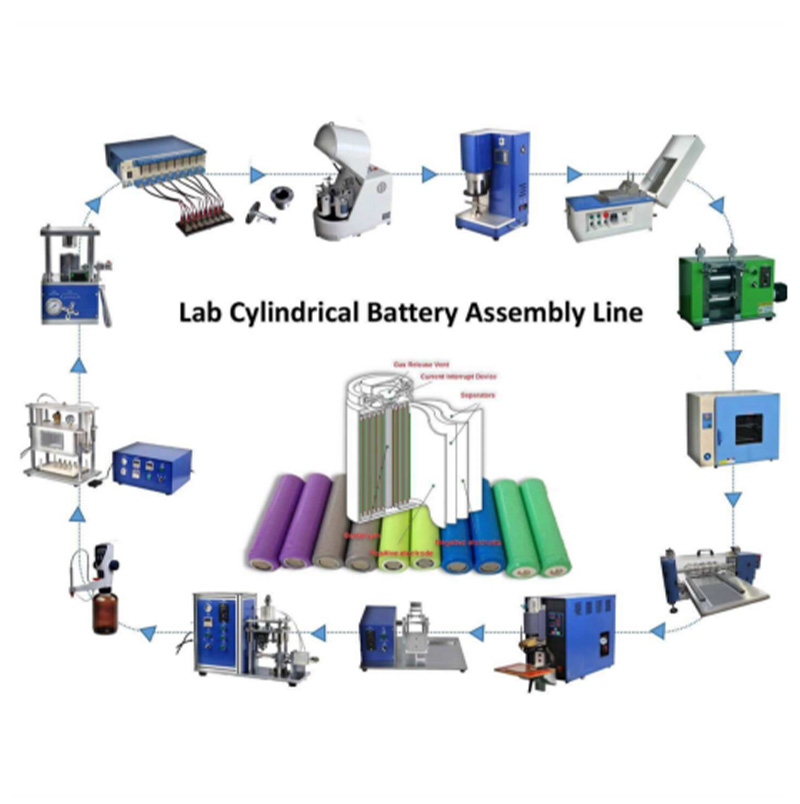

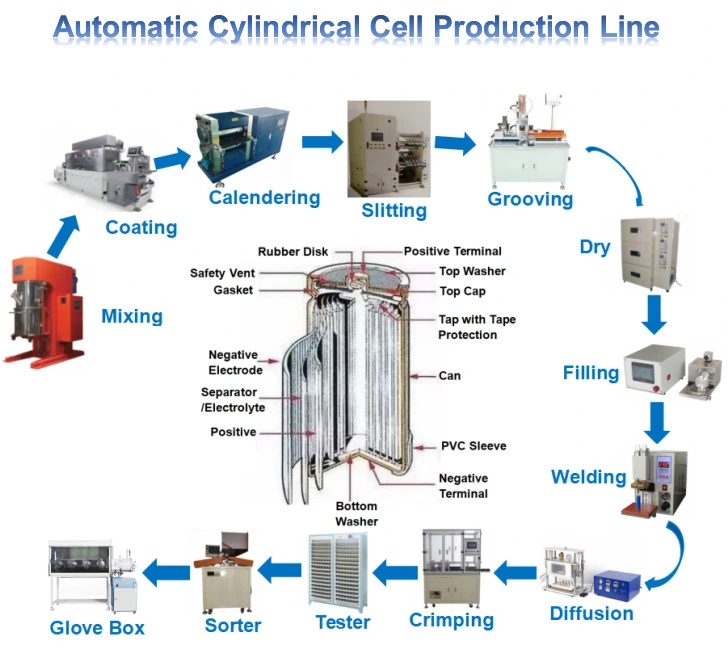

The cylindrical cell manufacturing process is a multi-stage, highly intricate sequence that demands extreme precision and cleanliness. It begins with raw material preparation and culminates in the testing and sorting of finished cells. Below is a detailed breakdown:

1. Electrode Preparation

- Slurry Mixing: Active materials (e.g., NMC, LFP for cathode; graphite, silicon-carbon for anode), conductive additives, and binders are meticulously mixed with a solvent to form a homogeneous slurry. This stage is critical for electrochemical performance.

- Coating and Drying: The anode and cathode slurries are precisely coated onto thin metal foils (copper for anode, aluminum for cathode) using advanced coating machines. These coated foils then pass through drying ovens to remove solvents, ensuring uniform adhesion and preventing defects.

- Calendering: The dried electrodes are compressed using high-precision rollers to achieve the desired thickness and porosity. This process, known as calendering, significantly impacts the cell's energy density and power capability.

- Slitting: The wide electrode rolls are then slit into narrower strips of precise width, suitable for the subsequent winding or stacking process.

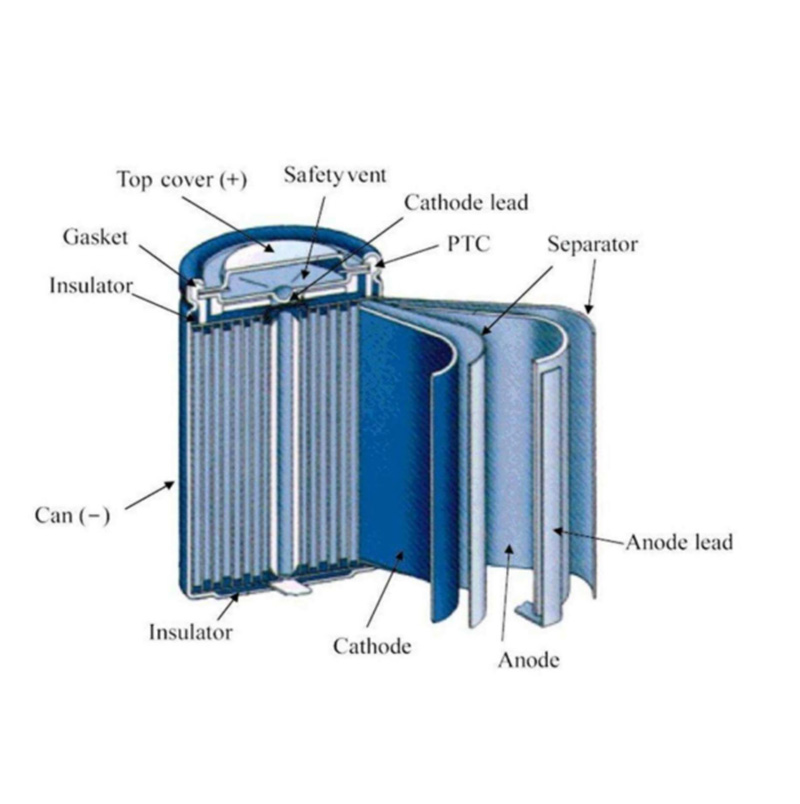

2. Cell Assembly (Jelly Roll Formation)

- Winding: This is a core part of cylindrical cell assembly. The slit anode, separator, and cathode foils are precisely wound together into a compact cylindrical structure, often called a 'jelly roll.' High-speed, high-accuracy winding machines are essential here to prevent misalignments or wrinkles that could lead to short circuits or reduced performance.

- Tab Welding: Current collector tabs (typically nickel for anode, aluminum for cathode) are welded to the respective electrode foils of the jelly roll. Laser welding or ultrasonic welding ensures robust electrical connections.

- Jelly Roll Insertion: The completed jelly roll is carefully inserted into a metal can (typically steel or aluminum).

3. Electrolyte Filling and Sealing

- Electrolyte Injection: A precisely measured amount of liquid electrolyte is injected into the cell can under vacuum conditions to ensure complete impregnation of the separator and electrodes. The electrolyte facilitates ion transfer between electrodes.

- Sealing: The cell is hermetically sealed using a cap assembly, often involving crimping and laser welding. This prevents electrolyte leakage and protects the cell from external contaminants, ensuring a long service life and stability.

4. Formation and Aging

- Formation Cycling: The newly assembled cells undergo initial charge and discharge cycles under controlled conditions. This process, known as formation, forms the Solid Electrolyte Interphase (SEI) layer on the anode, which is crucial for long-term cell stability and performance.

- Aging: After formation, cells are aged for a period (typically days) at elevated temperatures. This step allows for the stabilization of the SEI layer and helps identify any latent defects, ensuring only high-quality cells proceed to the next stage.

5. Testing and Sorting

- Electrical Testing: Each cell undergoes rigorous electrical tests, including Open Circuit Voltage (OCV), Internal Resistance (ACIR), capacity, self-discharge rate, and impedance measurements. These tests adhere to stringent standards, often including ISO and relevant industry benchmarks for battery safety and performance.

- Sorting: Based on the test results, cells are precisely sorted into different grades (e.g., A-grade, B-grade) according to their performance characteristics, ensuring consistent quality for various applications.

- Inspection and Packaging: Final visual inspections confirm cosmetic quality, followed by packaging for shipment.

Schematic representation of key stages in cylindrical cell production.

Technical Specifications and Parameters of Advanced Production Lines

A state-of-the-art cylindrical cell manufacturing line, such as those designed for 18650, 21700, 26650, and 32650 cells, is characterized by its high throughput, precision, and integration. Key technical parameters define the capability and efficiency of such a line:

Key Production Line Parameters

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Throughput (Cells/Minute) | Rate of finished cells produced per minute. | Up to 200-400 cells/min (per line module) |

| Automation Level | Degree of automated processes, from material feeding to final sorting. | Semi-automatic to Fully Automatic (Level 4-5) |

| Production Yield | Percentage of good cells produced relative to total input. | > 98% (Post-formation and sorting) |

| Precision (μm) | Accuracy of electrode alignment, coating thickness, winding tension. | ± 5-10 μm (Coating), ± 20-50 μm (Winding) |

| Cleanroom Class | Required environmental cleanliness for critical processes. | ISO Class 7 (Class 10,000) or higher |

| Footprint (m²) | Space required for the entire production line. | Varies (e.g., 500-2000 m² for full line) |

| Power Consumption (kW) | Total power demand of the integrated system. | 100-500 kW (depending on scale) |

| Supported Cell Sizes | Range of cylindrical cell diameters and heights accommodated. | 18650, 21700, 26650, 32650, etc. |

These parameters are crucial for potential investors and battery manufacturers to assess the suitability and return on investment of a given production line. Achieving high values across these metrics often signifies a highly optimized and advanced system capable of meeting stringent market demands.

High-precision winding module in a modern cylindrical cell production line.

Technical Advantages of Advanced Cylindrical Cell Manufacturing Lines

Investing in an advanced production line for cylindrical cell manufacturing offers numerous technical and operational advantages:

- Superior Cell Quality and Consistency: Automated systems minimize human error, leading to tighter tolerances, consistent electrode coating, and precise cell assembly, which translates to uniform cell performance and extended service life. Adherence to standards like ISO 9001 ensures a robust quality management system throughout the entire production cycle.

- Enhanced Production Efficiency and Throughput: High-speed robotics and integrated process controls drastically reduce cycle times and increase overall output, allowing manufacturers to meet surging market demand effectively.

- Optimized Resource Utilization: Advanced lines feature energy-efficient components, precise material dispensing, and reduced waste generation. For instance, optimized drying processes and solvent recovery systems contribute to significant energy savings and reduced environmental impact.

- Improved Safety Protocols: Automated handling of hazardous materials and reduced human intervention in critical, high-energy processes enhance worker safety, minimizing exposure to chemicals and reducing risks associated with high-voltage testing.

- Scalability and Flexibility: Modular designs allow for easy upgrades, capacity expansion, or adaptation to new cell formats (e.g., transitioning from 18650 to 21700 or 32650) with minimal retooling, future-proofing the investment.

- Data-Driven Process Control: Integrated sensors and data analytics platforms provide real-time monitoring and feedback, enabling proactive adjustments to maintain optimal conditions and improve yield. This allows for predictive maintenance and significantly reduces downtime.

These advantages are critical for battery manufacturers looking to produce reliable, high-performance cells competitively for demanding applications across various industries.

Application Scenarios and Target Industries

Cylindrical cells are fundamental to numerous high-growth sectors, making advanced production lines indispensable for manufacturers targeting these markets. The cylindrical cell manufacturing solutions cater primarily to battery cell producers that supply:

- Electric Vehicles (EVs): Cylindrical cells are favored by several major automotive manufacturers for their thermal management characteristics and structural integrity, crucial for high-power battery packs in electric cars, buses, and trucks.

- Energy Storage Systems (ESS): From residential to grid-scale applications, battery energy storage is vital for renewable energy integration and grid stabilization. Cylindrical cells offer the reliability and modularity required for these large-scale systems.

- Consumer Electronics: Laptops, power tools, e-bikes, and other portable devices rely heavily on cylindrical cells for their energy density and form factor.

- Medical Devices: Precision and reliability are paramount in medical equipment. Cylindrical cells provide the consistent power delivery needed for devices like portable medical ventilators and diagnostic tools.

- Robotics and Drones: High power-to-weight ratio and compact size make cylindrical cells ideal for powering industrial robots, autonomous guided vehicles (AGVs), and various drone applications.

The demand for consistent quality and high volumes across these industries drives the need for technologically advanced cylindrical cell manufacturing lines.

Automated cell sorting and inspection system in a battery factory.

Vendor Comparison: Choosing the Right Partner for Your Production Line

Selecting the right vendor for a cylindrical cell manufacturing line is a critical decision that impacts long-term operational efficiency and profitability. Key differentiators include:

| Feature/Criterion | Vendor A (e.g., Specialized Automation) | Vendor B (e.g., Global Integrator) | Vendor C (e.g., Cost-Optimized Provider) |

|---|---|---|---|

| Technology Innovation | High, patented winding/coating tech, advanced AI integration. | Moderate-High, focus on proven, scalable solutions. | Standard, reliable, less bleeding-edge. |

| Customization & Flexibility | Excellent, tailor-made for specific cell chemistries/sizes. | Good, modular design, some configuration options. | Limited, standardized modules, fixed configurations. |

| After-Sales Support & Service | Global 24/7 support, dedicated technicians, extensive spare parts. | Regional support centers, comprehensive training. | Basic remote support, limited on-site visits. |

| Total Cost of Ownership (TCO) | Higher initial cost, lower long-term operational cost due to efficiency. | Moderate, balanced initial and operational costs. | Lower initial cost, potentially higher long-term maintenance. |

| Experience & Certifications | Decades in battery automation, ISO, CE, UL certified, Tier 1 client base. | Established presence, ISO, CE certified, diverse client portfolio. | Newer entrant, basic certifications, emerging client base. |

This comparison helps prospective buyers evaluate vendors based on their strategic priorities, whether it's leading-edge technology, cost efficiency, or robust global support.

Customized Solutions for Advanced Battery Production

The diverse requirements of battery manufacturers necessitate highly customizable cylindrical cell manufacturing solutions. A one-size-fits-all approach is rarely effective given the evolving nature of cell chemistries, formats, and market demands. We specialize in providing bespoke production lines, tailored to specific client needs:

- Cell Format Agility: Lines can be configured to produce a range of cylindrical cell sizes (e.g., 18650, 21700, 26650, 32650) with quick changeover capabilities, optimizing flexibility for market shifts.

- Capacity Scalability: From pilot lines for R&D to giga-factory scale production, solutions are designed for phased expansion, allowing manufacturers to scale operations in alignment with market growth.

- Material and Chemistry Specificity: Customization extends to accommodating various electrode materials (NMC, LFP, NCA, Si-anodes) and electrolyte compositions, ensuring process compatibility and optimal cell performance.

- Integration with Existing Infrastructure: Seamless integration with existing factory layouts, utility systems, and MES/ERP systems minimizes disruption and maximizes operational synergy.

- Specific Automation Levels: Clients can specify the desired level of automation, from semi-automatic lines for specialized production to fully automated, lights-out facilities for mass production, balancing investment with labor costs.

Our engineering teams work closely with clients to develop a comprehensive understanding of their operational objectives, current infrastructure, and future expansion plans, delivering a production line that is perfectly aligned with their strategic goals.

Application Case Studies: Realizing Production Excellence

Our advanced cylindrical cell manufacturing lines have empowered numerous clients globally to achieve their production targets and enhance market competitiveness. Here are illustrative examples of our impact:

Case Study 1: High-Volume EV Battery Manufacturer

- Challenge: A leading EV battery manufacturer required a high-throughput, highly automated line for 21700 cells to meet escalating demand from automotive OEMs, with stringent requirements for quality and consistency.

- Solution: We delivered a fully integrated, modular production line featuring advanced laser welding systems, precision winding machines capable of 300+ cells/minute, and AI-driven quality inspection. The line was designed for ISO Class 7 cleanroom compatibility and real-time data integration.

- Result: The client achieved a 30% increase in overall production capacity within the first year, maintained a yield rate above 99.5%, and reported a significant reduction in defect rates, strengthening their position as a Tier 1 supplier for electric vehicles.

Case Study 2: Innovative Energy Storage Solutions Provider

- Challenge: An innovator in residential ESS needed a flexible production line to produce both 26650 and 32650 cylindrical cells with varying chemistries, requiring rapid changeover capabilities and robust performance testing.

- Solution: We engineered a versatile line with automated module exchange capabilities for different cell formats and an integrated electrochemical impedance spectroscopy (EIS) system for comprehensive cell characterization during formation.

- Result: The client successfully diversified their product portfolio, launched new ESS products faster, and gained a competitive edge by offering highly optimized cells. The flexible line reduced changeover times by 70%, boosting operational agility.

A section of an automated production line for cylindrical cell assembly.

Ensuring Quality, Trust, and Support ( Principles)

Our commitment to excellence in cylindrical cell manufacturing solutions is underpinned by adherence to stringent quality standards, transparent practices, and robust customer support. This foundation builds trust and demonstrates our expertise and authoritativeness.

Certifications and Compliance

Our production lines and processes comply with international standards including:

- ISO 9001: Quality Management Systems, ensuring consistent product and service quality.

- ISO 14001: Environmental Management Systems, reflecting our commitment to sustainable practices.

- CE Marking: Compliance with European health, safety, and environmental protection standards.

- ANSI/UL Standards: Where applicable, equipment designed to meet specific safety standards for North American markets.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a full cylindrical cell assembly line?

A: Lead times vary based on customization and scope, typically ranging from 6 to 18 months from order confirmation to factory acceptance testing (FAT).

Q: What warranty is provided with your production lines?

A: We offer a standard 12-month warranty on parts and labor, extendable based on service level agreements. This covers manufacturing defects and ensures operational reliability.

Q: Do you offer training for our operational staff?

A: Yes, comprehensive on-site training is a core part of our service package, covering operation, routine maintenance, and troubleshooting to empower your team.

Q: How do you ensure product quality post-installation?

A: Beyond FAT and site acceptance testing (SAT), we provide ongoing technical support, remote diagnostics, and preventative maintenance schedules to ensure sustained high performance and yield.

Lead Time & Fulfillment

Our project management adheres to strict timelines, ensuring efficient delivery and installation. From initial consultation to full commissioning, our team provides clear communication and meticulous planning, with typical fulfillment taking 6-18 months depending on the scale and customization of the cylindrical cell manufacturing solution.

Warranty and After-Sales Support

We stand behind the quality and reliability of our production lines with comprehensive warranty packages. Our global after-sales support includes 24/7 technical assistance, remote diagnostics, on-site service by expert engineers, and readily available spare parts to minimize downtime and maximize the operational lifespan of your investment.

Conclusion

The landscape of energy storage is rapidly evolving, with cylindrical lithium-ion cells playing a crucial role across myriad applications. The ability to produce these cells with high precision, efficiency, and scalability through advanced cylindrical cell manufacturing lines is a key differentiator for battery manufacturers. By embracing automation, digitalization, and customized solutions, companies can not only meet current market demands but also future-proof their operations against emerging technological shifts and increasing competition. Investing in a robust and technologically superior production line is an investment in the future of energy.

References

- Li, J., Daniel, C., & Wood, D. L. (2011). Materials and manufacturing processes for lithium-ion battery electrodes. Journal of Power Sources, 196(10), 5122-5129.

- Song, J., Ryou, M. H., Lee, Y. M., Choi, J. W., & Kim, H. (2014). High-performance manufacturing of lithium-ion batteries. Journal of Energy Chemistry, 23(1), 1-12.

- Ma, L., Cheng, X., Zhang, Y., & Wei, X. (2018). Advanced manufacturing technologies for power battery cells. Energy Storage Materials, 13, 230-247.

- International Electrotechnical Commission (IEC). (2020). Secondary cells and batteries containing alkaline or other non-acid electrolytes – Safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications – Part 1: Nickel-cadmium. IEC 62133-1:2020.

- National Renewable Energy Laboratory (NREL). (2022). Battery Manufacturing: Process and Cost Analysis. NREL/TP-5400-82601.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025