Round Metal File—Need Precise Finishing for Any Diameter?

round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Hand tool manufacturing. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file Overview

- Benefits & Use Cases of round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file in Hand tool manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file from XINGTAI SHUODING TRADING CO.,LTD

round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file Overview

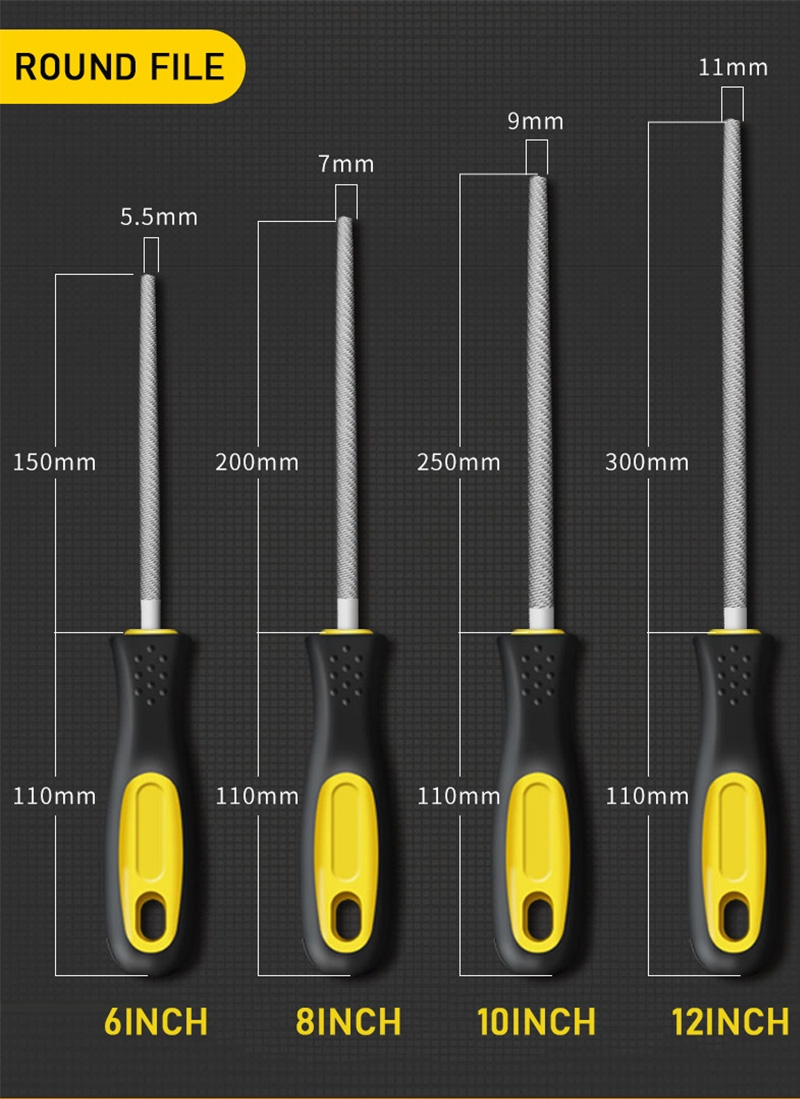

A round metal file—often called a small round file, rat-tail file, or simply a round file—is a precision hand tool used to deburr, enlarge, and finish circular profiles, grooves, keyways, and holes in metals and hard plastics. In the General equipment manufacturing industry and Hand tool manufacturing, these files are indispensable for accurate fit-up work, prototype adjustments, and post-machining refinement where milling or drilling leaves burrs and tight radii. Popular diameters include the 1 8 round file (approximately 3.175 mm), the 5 32 round file (about 3.97 mm), and the 4.5 mm round file, each chosen to match target geometries and component tolerances.

Technical considerations for buyers include steel grade, hardness, tooth pattern (single-cut vs. double-cut), shank/tang compatibility with handles, and overall length (commonly 4–8 inches for small round files). For high repeatability and consistent bite, look for files that maintain uniform tooth geometry along the working length and resist clogging on stainless or high-carbon steels. XINGTAI SHUODING TRADING CO.,LTD offers an extensive selection of round metal files engineered for durability and predictable cutting action, supporting OEM and MRO needs with dependable quality control and flexible packaging options suitable for B2B procurement.

Benefits & Use Cases of round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file in Hand tool manufacturing

In Hand tool manufacturing, engineers and technicians rely on the small round file to refine edges on plier jaws, screwdrivers, chisels, and precision fixtures where circular clearance and smooth radii are critical. The 1 8 round file excels at micro-adjustments in jigs and thin-walled components, while the 5 32 round file is a go-to for chainsaw sharpening, deburring drilled holes, and cleaning up tubing ends. For metric assemblies and electronics enclosures, a 4.5 mm round file helps achieve consistent cable passthroughs and precise dowel-fit holes without introducing chatter marks.

Key advantages include controllable stock removal, access to tight spaces, and low total setup time compared to machining rework. XINGTAI SHUODING TRADING CO.,LTD’s round metal file portfolio features sharp, uniform teeth for aggressive yet clean cutting, well-tempered bodies for long service life, and comfortable tangs for firm handle fitment. The company’s breadth of SKUs—across diameters, lengths, and cut patterns—lets B2B buyers standardize on a single supplier, simplifying inventory and ensuring consistent performance across work cells and production lines.

Cost, Maintenance & User Experience

From a total cost of ownership perspective, a well-made round metal file reduces rework, scrap, and tool changeovers. When operators can achieve specification with a single pass using a 1 8 round file or 5 32 round file, cycle times drop and throughput improves. XINGTAI SHUODING TRADING CO.,LTD focuses on long-wearing tooth profiles and robust heat treatment, which translates into fewer replacements and lower lifetime spend per workstation. For applications involving mixed materials, having both imperial and metric options—such as a 4.5 mm round file—keeps teams agile and reduces downtime spent sourcing special sizes.

Maintenance is straightforward: use a file card or stiff brush to clear swarf regularly, apply chalk to reduce pinning on soft metals, and store files so teeth do not contact each other. Many B2B users in the General equipment manufacturing industry report improved surface finish and reduced burr reappearance when switching to premium small round file variants. Ergonomic handles and consistent tang dimensions further enhance user experience, reducing slippage and operator fatigue over long shifts.

Sustainability & Market Trends in manufacturing

As manufacturers pursue leaner, greener operations, durable hand tools play a quiet but meaningful role. A long-life round metal file reduces the frequency of replacement and associated logistics, packaging, and scrap. Selecting the right size—whether a 5 32 round file for chain link finishing or a 4.5 mm round file for metric housings—minimizes overworking, saves energy in downstream processes, and helps maintain first-pass yield. Additionally, a compact toolkit of small round file sizes supports on-site rework, lowering the need for machine-intensive corrective operations.

Market demand is trending toward tighter tolerances, ergonomic handles, and assortments that blend imperial and metric standards. Buyers increasingly value traceable materials and consistent performance across global production sites. XINGTAI SHUODING TRADING CO.,LTD aligns with these priorities by emphasizing quality consistency, thoughtful packaging to reduce waste, and a product range that supports both legacy and next-gen assemblies. By keeping inventories aligned to common diameters—such as the 1 8 round file—procurement teams can streamline SKUs without compromising capability.

Conclusion on round metal file, small round file, 1 8 round file, 5 32 round file, 4.5 mm round file from XINGTAI SHUODING TRADING CO.,LTD

For B2B decision makers in manufacturing, a well-specified round metal file is a small investment with outsized impact on quality, throughput, and flexibility. Whether you need a small round file for delicate deburring, a 1 8 round file for tight radii, a 5 32 round file for sharpening and hole finishing, or a 4.5 mm round file for metric assemblies, XINGTAI SHUODING TRADING CO.,LTD delivers reliable, high-performance options backed by attentive service.

Contact us: email: sdtrading0927@126.com

Visit our website: https://www.xtshuoding.com

Explore the product page: Round File Products

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025