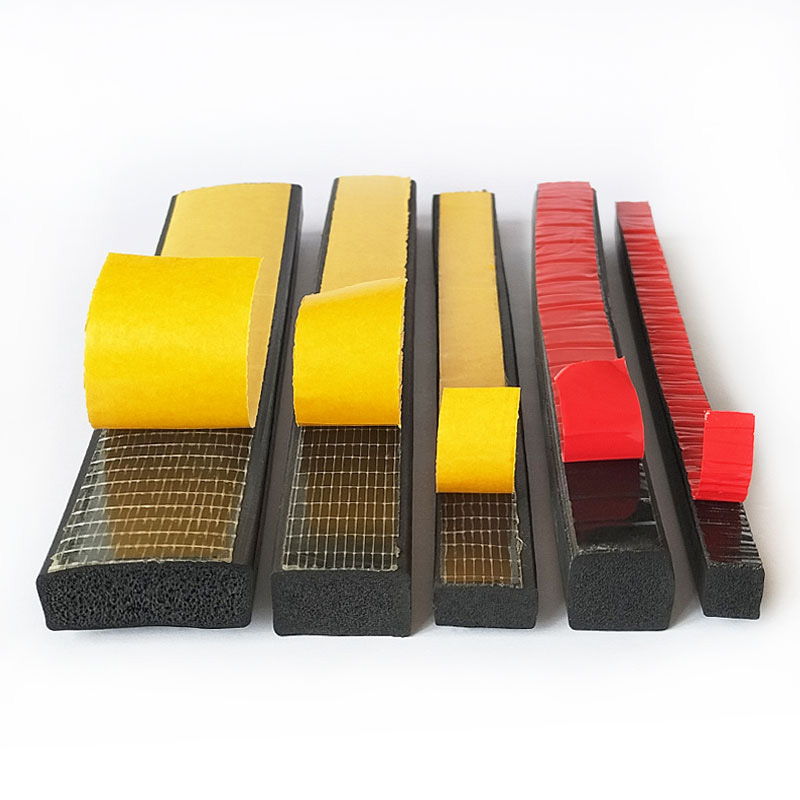

s type rubber seal strip

Understanding Rubber Seal Strips Types and Applications

Rubber seal strips are essential components in various industries, providing airtight and watertight seals that help maintain product integrity and efficiency. These strips are made from different types of rubber, designed to withstand specific environmental conditions. This article will explore the various types of rubber seal strips and their applications.

Types of Rubber Seal Strips

1. EPDM Rubber (Ethylene Propylene Diene Monomer) Known for its excellent weather resistance, EPDM is ideal for outdoor applications. It remains flexible in extreme temperatures and is resistant to UV radiation, ozone, and various chemicals. Commonly used for vehicle weatherstripping and roofing projects, EPDM seal strips help prevent water ingress and reduce energy loss.

2. Neoprene Rubber This synthetic rubber is popular for its resilience and versatility. Neoprene seal strips are resistant to oil, chemicals, and heat, making them suitable for industrial applications. They are often used in automotive and construction industries to seal gaps in machinery, windows, and doors.

3. Silicone Rubber Silicone seal strips are known for their high temperature and extreme weather resistance. They remain flexible over a wide range of temperatures, making them perfect for kitchen appliances, medical devices, and automotive applications. Silicone’s non-reactive nature also makes it an excellent choice for food-grade seals.

s type rubber seal strip

4. Nitrile Rubber (Buna-N) Nitrile seal strips are primarily used in applications where oil and fuel resistance is critical. This rubber type is commonly used in the automotive industry and for fuel-handling equipment.

Applications of Rubber Seal Strips

Rubber seal strips can be found in a myriad of applications across various industries

- Automotive Used in doors, windows, and hoods to prevent water and wind leaks, enhancing driver comfort and vehicle durability. - Construction Used in windows, doors, and HVAC systems to provide thermal insulation and prevent water penetration, thus improving energy efficiency. - Consumer Appliances Found in refrigerators and dishwashers, rubber seals help maintain the necessary temperature and prevent leaks. - Industrial Equipment Used to protect components from dust, moisture, and chemicals in machinery and equipment, thus ensuring longevity and reliability.

Conclusion

Choosing the right type of rubber seal strip is crucial for ensuring optimal performance in any given application. By understanding the different types of rubber and their specific properties, manufacturers and consumers can better select seal strips that meet their needs. Whether it’s for automotive, construction, or everyday household appliances, rubber seal strips play a vital role in enhancing functionality and durability. Investing in quality rubber seals can lead to long-term benefits, including energy savings, reduced maintenance costs, and improved product performance.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025