يانۋار . 09 , 2025 10:54

Back to list

lead acid battery production line

In the rapidly evolving realm of battery technology, having the right battery production equipment line can be the distinguishing factor between a leading innovator and an industry follower. Creating a streamlined, efficient, and cost-effective production line is crucial for any company looking to make substantial inroads into battery manufacturing. This requires not only investment into state-of-the-art machinery but also an understanding of the underlying elements that contribute to a successful production environment.

When it comes to authoritativeness, having a leadership role or being at the cutting edge of battery technology development lends significant credibility. Partnerships with research institutions and continuous investment in R&D highlight a commitment to not just keeping pace with, but driving, industry advancements. Companies that publish findings or collaborate on ground-breaking research help in setting industry standards and benchmarks. This not only reinforces their authority in the field but also builds trust with consumers and partners who are now more likely to view them as a trusted source of cutting-edge battery solutions. Trustworthiness in the battery production equipment line context is most clearly demonstrated through transparency and adherence to international safety and quality standards. Implementing ISO certification and ensuring compliance with environmental regulations fortify a manufacturer's standing in the eyes of discerning customers. Additionally, providing detailed documentation and regular updates on equipment maintenance and performance can further assure stakeholders of the commitment to quality and sustainability. This transparency should extend to materials sourcing, with clear reports indicating ethical procurement practices and recycling initiatives, thus bolstering the manufacturer's credibility in an environmentally-conscious market. Ultimately, the integration of a sophisticated battery production equipment line is not only about hardware investment but also about an intelligent alignment of experience, expertise, authoritativeness, and trust. The synergy of these elements can catapult a company to the forefront of the battery manufacturing industry, ensuring it not only meets the demands of today but is also poised to tackle the challenges of tomorrow.

When it comes to authoritativeness, having a leadership role or being at the cutting edge of battery technology development lends significant credibility. Partnerships with research institutions and continuous investment in R&D highlight a commitment to not just keeping pace with, but driving, industry advancements. Companies that publish findings or collaborate on ground-breaking research help in setting industry standards and benchmarks. This not only reinforces their authority in the field but also builds trust with consumers and partners who are now more likely to view them as a trusted source of cutting-edge battery solutions. Trustworthiness in the battery production equipment line context is most clearly demonstrated through transparency and adherence to international safety and quality standards. Implementing ISO certification and ensuring compliance with environmental regulations fortify a manufacturer's standing in the eyes of discerning customers. Additionally, providing detailed documentation and regular updates on equipment maintenance and performance can further assure stakeholders of the commitment to quality and sustainability. This transparency should extend to materials sourcing, with clear reports indicating ethical procurement practices and recycling initiatives, thus bolstering the manufacturer's credibility in an environmentally-conscious market. Ultimately, the integration of a sophisticated battery production equipment line is not only about hardware investment but also about an intelligent alignment of experience, expertise, authoritativeness, and trust. The synergy of these elements can catapult a company to the forefront of the battery manufacturing industry, ensuring it not only meets the demands of today but is also poised to tackle the challenges of tomorrow.

Share

Previous:

Next:

Latest news

-

Uses of Jute Bags | Sustainable Jute ProductsNewsAug.12,2025

-

Types of Square Files and Their Uses in Modern IndustriesNewsAug.12,2025

-

Slitting Machines Overview & TypesNewsAug.12,2025

-

Jute Rope: The Versatile Material for DIY & CraftingNewsAug.12,2025

-

How to Use Tofu Cat Litter for the Best ResultsNewsAug.12,2025

-

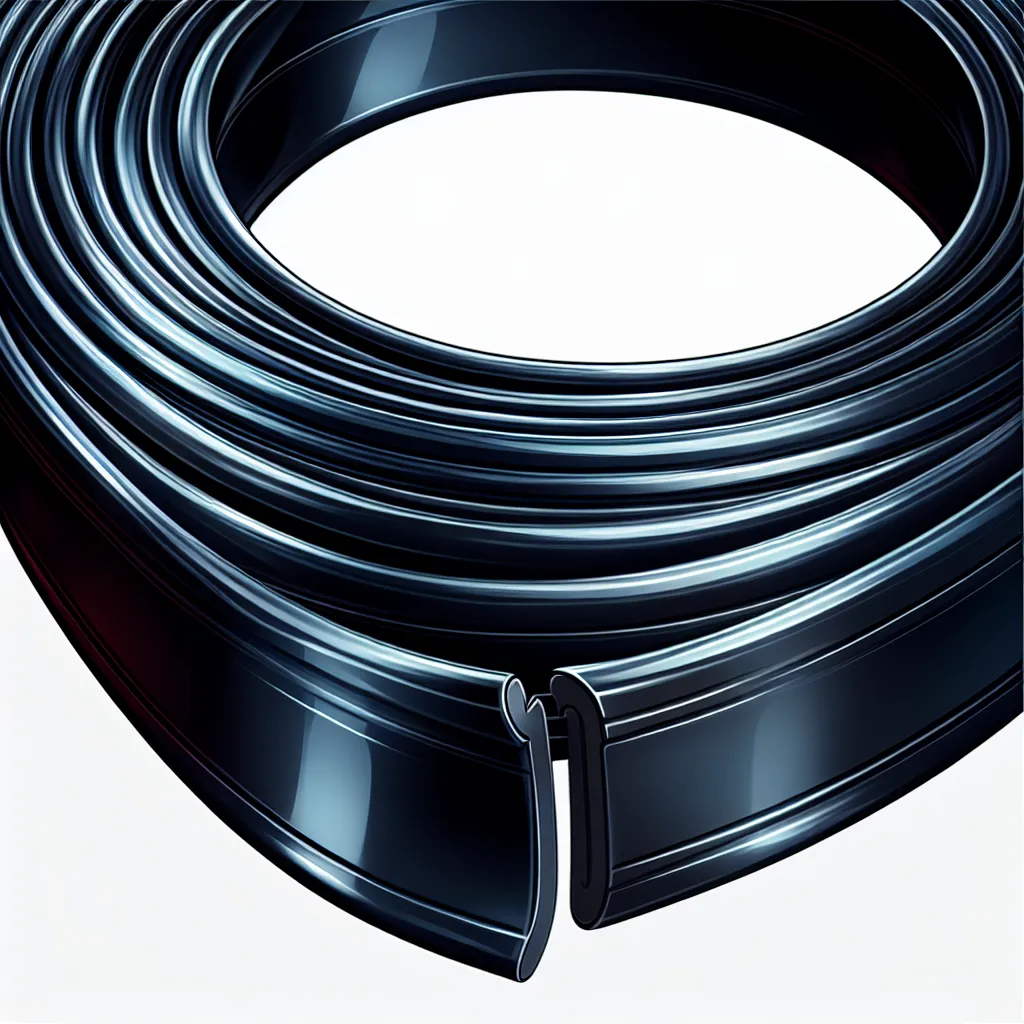

Car Door Seal Buying GuideNewsAug.12,2025