lntroduction

1:Prismatic Cell Manufacturing Machine

Turnkey Solution

Prismatic Cell Laboratory Line: 20 Pcs/day

Prismatic Cell Pilot Line: 100 MWH/year

Prismatic Cell Production Line: 1 GWH/year

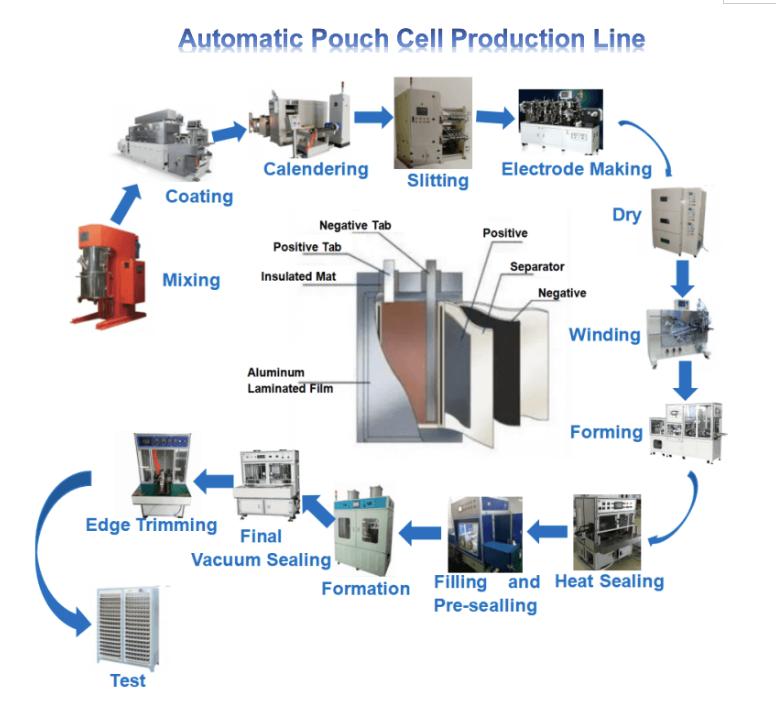

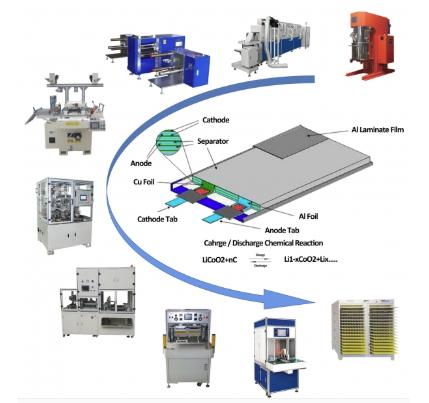

2:Pouch Cell Laboratory Line: Manual coater, Stacking machine, Sealing mahcine, Ultrasonic welder

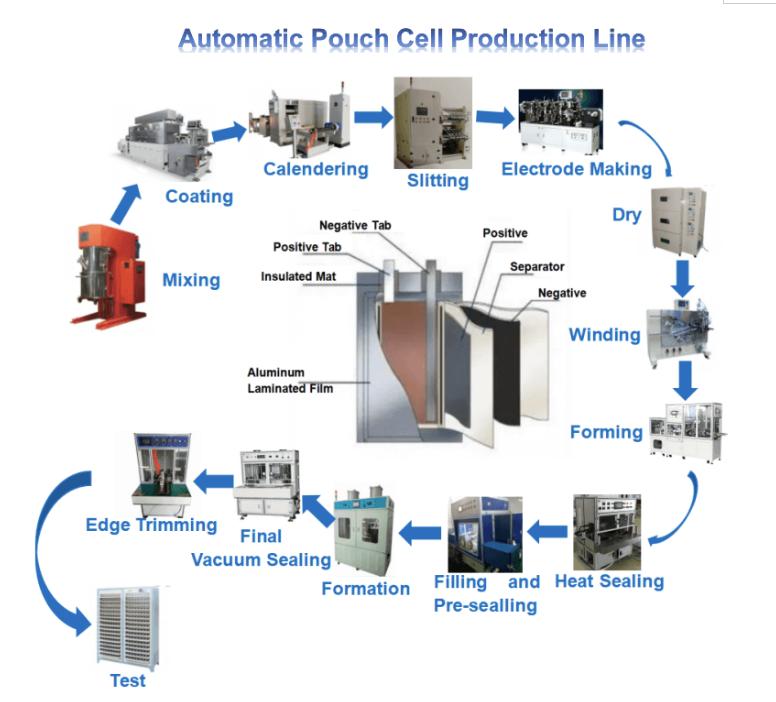

Pouch Cell Production Line: Auto Stacking machine, Slot die coater, Hydraulic calendar,Forming machine

Pouch cell is a flexible and lightweight rechargeable battery. It features a flat, pouch-like package that holds the battery's active components. Pouch cells offer advantages such as high energy density, flexible form factor, excellent power delivery, lightweight design, improved thermal characteristics, and longer cycle life. These qualities make pouch cells a preferred choice for applications in portable electronics, electric vehicles, and renewable energy systems.

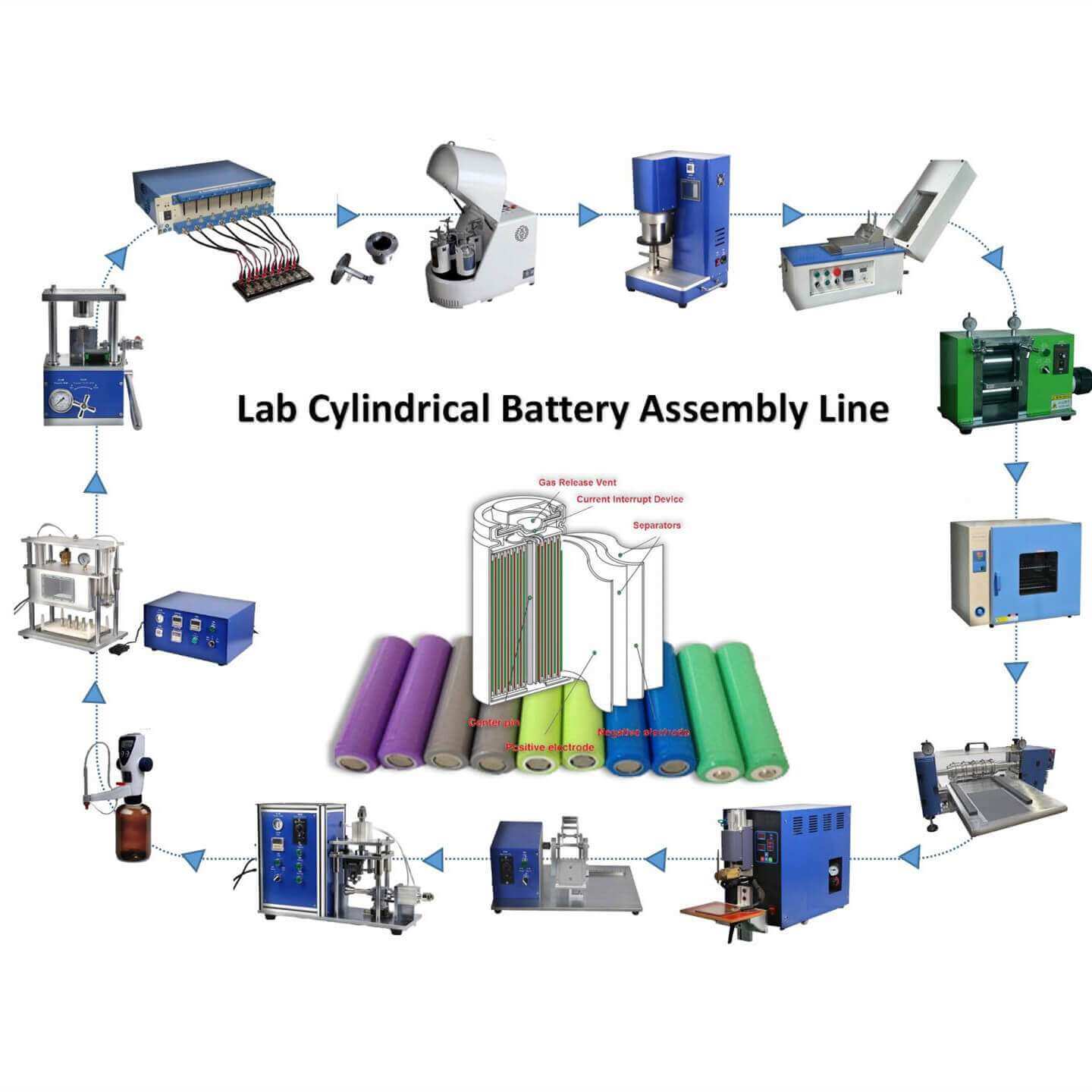

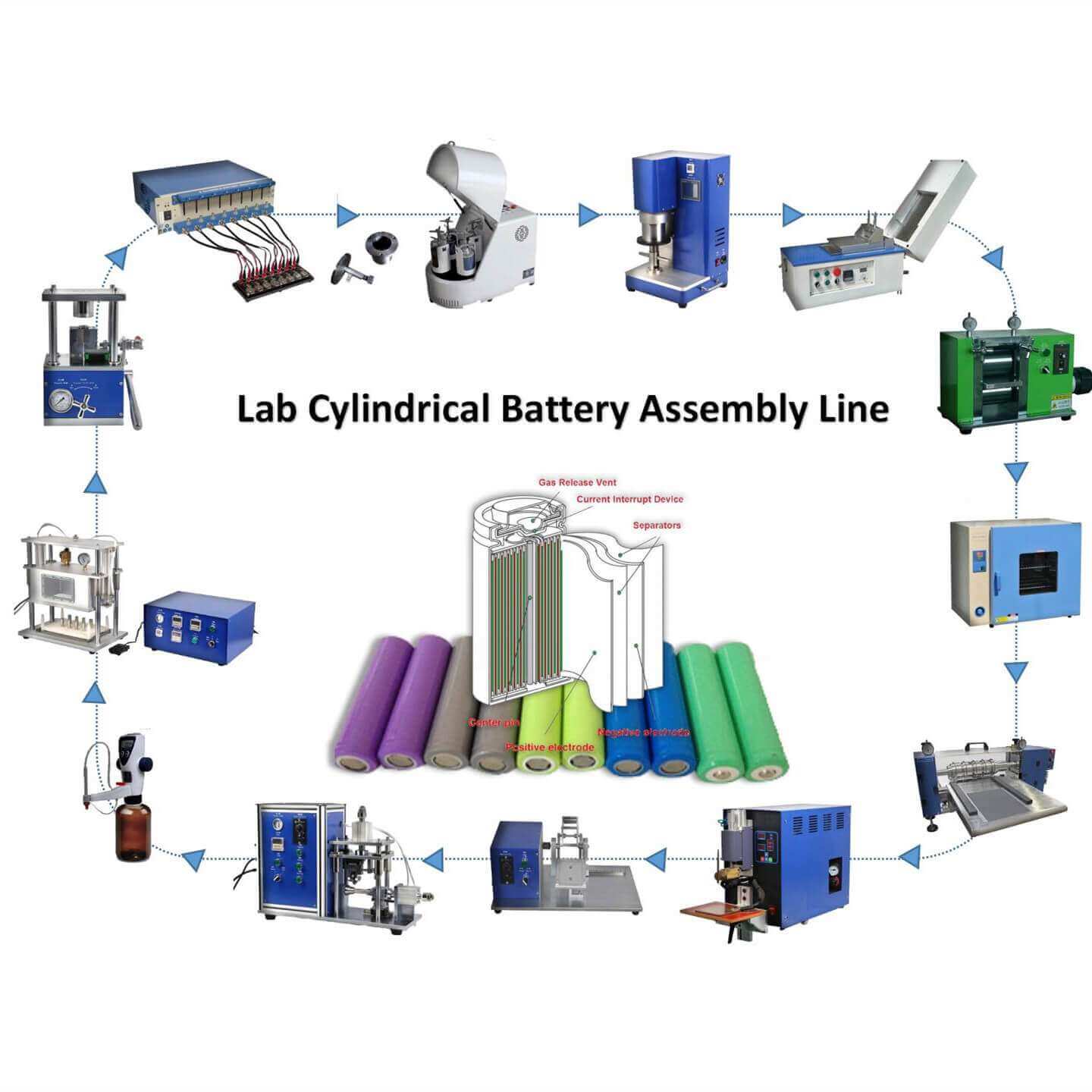

3:Cylindrical Cell Laboratory Line:

Manual coater, Roller press machine, winding machine。

18650 26650 21700 32650 Cylindrical Cell Laboratory Fabrication Plant.

Automatic 18560 21700 32650 26650 Etc Cylindrical Cell Production Line/Lithium Cylindrical Battery Production Plant.

Cylindrical Cell Production Line:

Auto winding machine, Roll to roll coater, Auto slitter, etc

Material System: LFP/NMC/LTO

Capacity: 30Ah 50Ah 100Ah 200Ah

Customization available upon request

Email:sdtrading0927@126.com

100MWH EV Battery LFP/NCM Prismatic Cell Manufacturing Line Pilot Line Turn Key Solution

Model Number: SD-PCML-01

Compliance:CE Certified

Warranty:One Year limited warranty with lifetime support

Shipping Port:TIANJIN Port

- WhatsApp/Wechat: +86 13146799036

- Email : sdtrading0927@126.com

100MWH EV Battery LFP/NCM Prismatic Cell Manufacturing Line Pilot Line Turn Key Solution

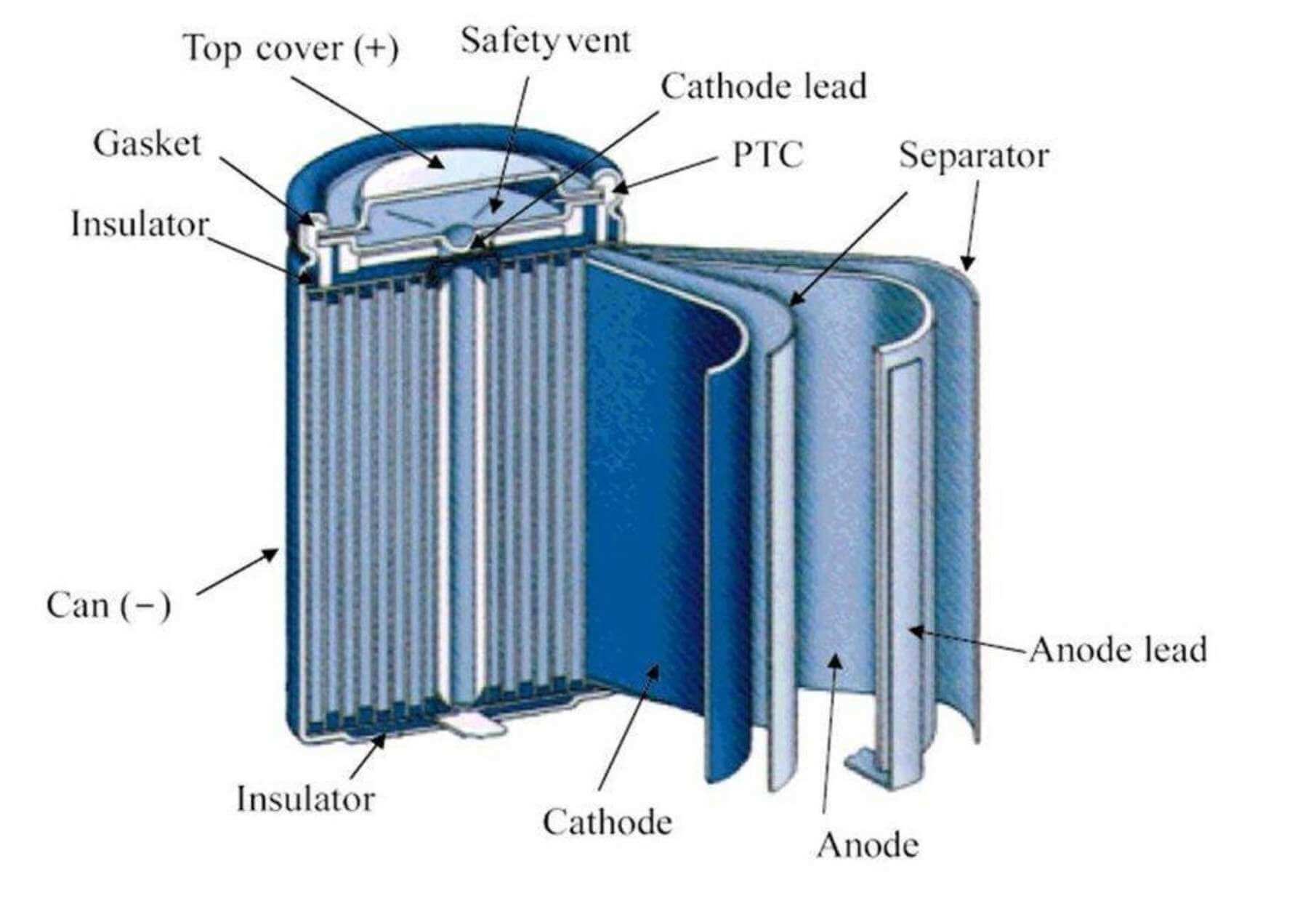

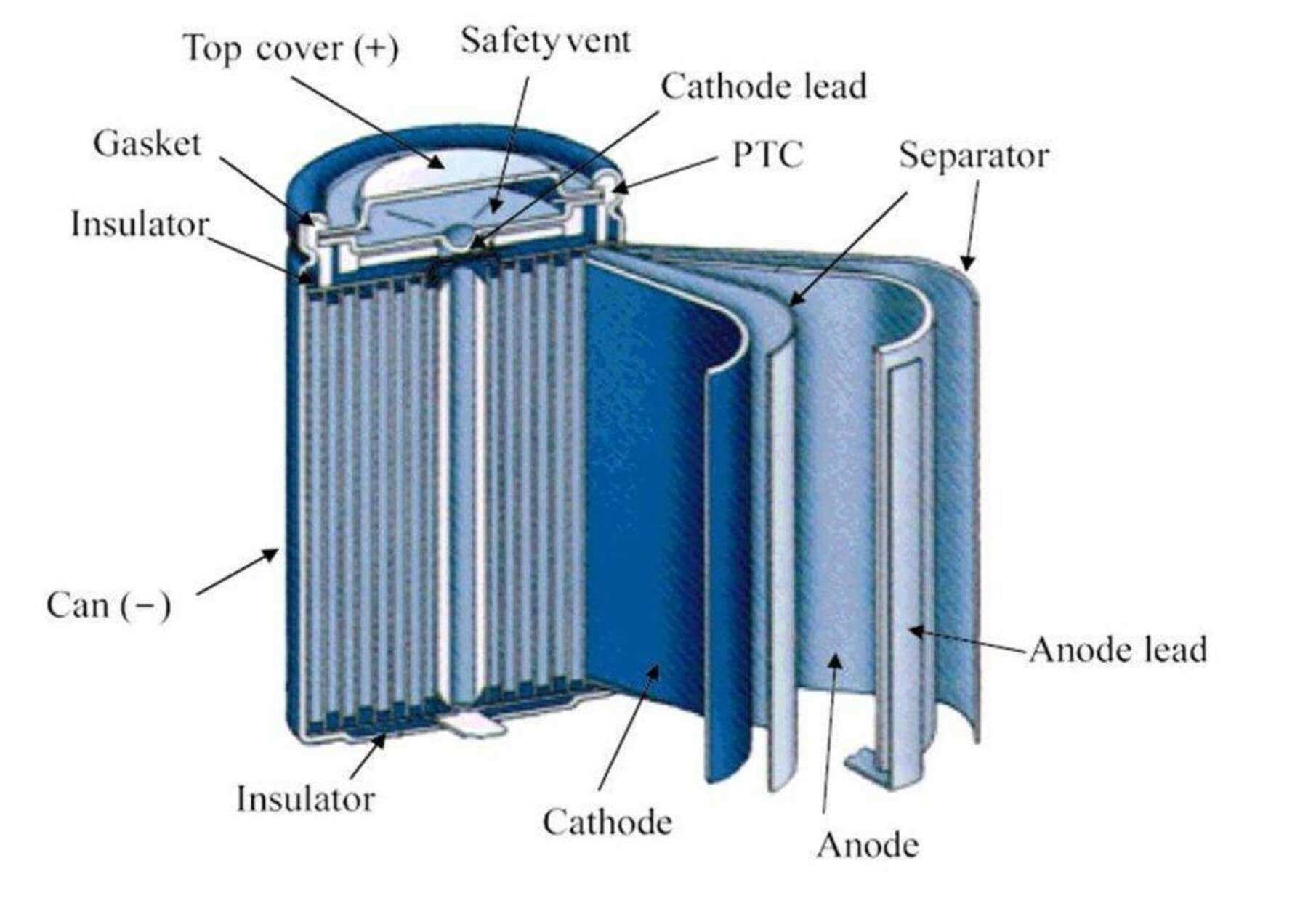

Introduction of prismatic cell

The shell of the prismatic cell is mostly made of aluminum alloy, stainless steel and other materials. The internal winding or stacking process is adopted, which has a better protective effect on the cell than the aluminum plastic film battery (i.e., the pouch cell). The cell safety has also been greatly improved compared with the cylindrical battery.

The popularity rate of prismatic cell is very high in China. With the rise of automobile power battery in recent years, the contradiction between vehicle range and battery capacity has become increasingly prominent.

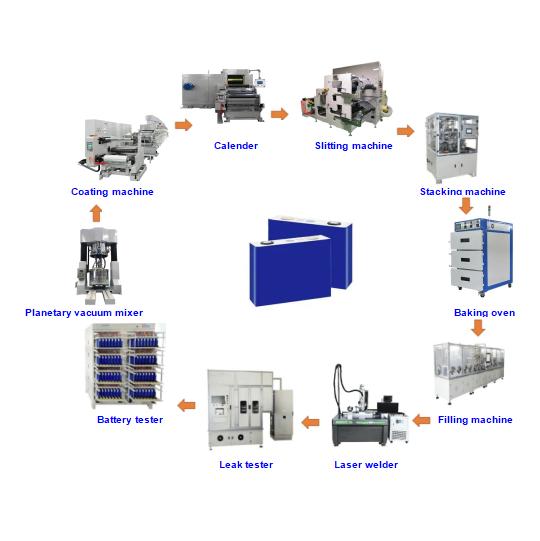

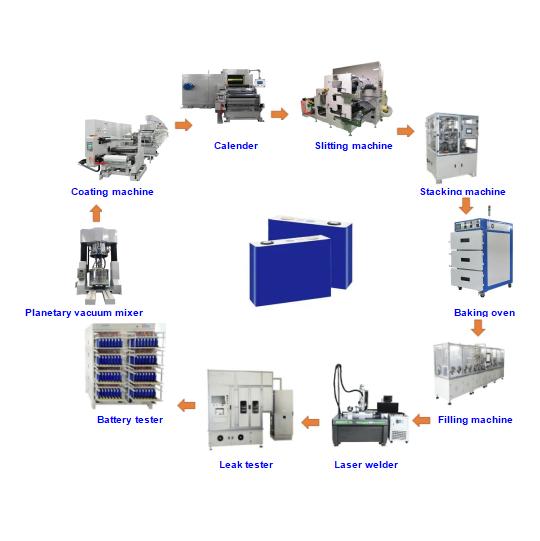

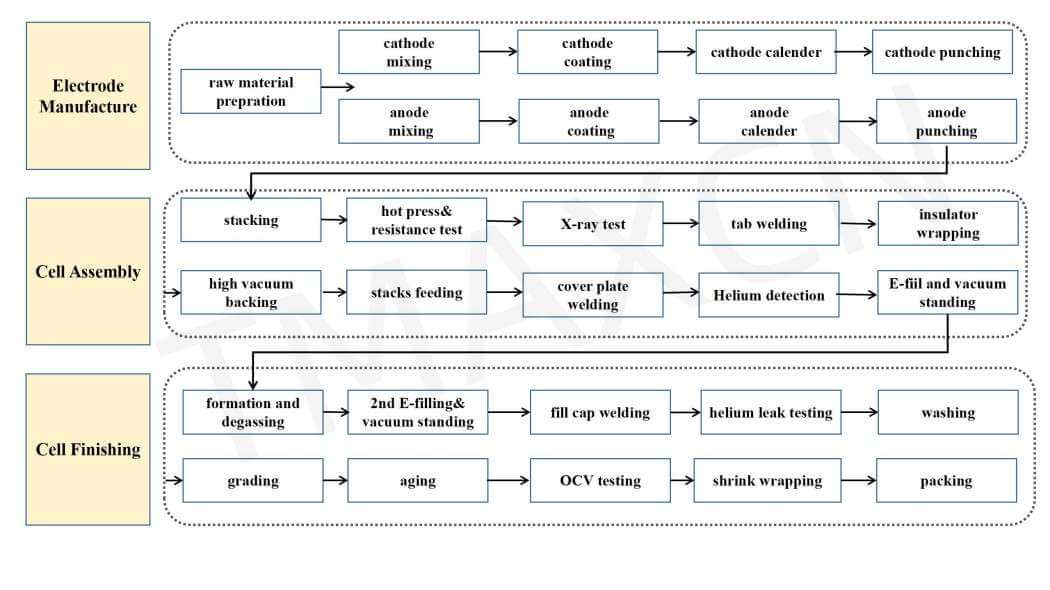

Production process flow

Equipment List

|

S NO. |

Equipment |

|

1 |

Cathode Mixer |

|

2 |

Anode Mixer |

|

3 |

Cathode Slot Die Coater |

|

4 |

Anode Slot Die Coater |

|

5 |

NMP Recovery System |

|

6 |

Cathode Calender |

|

7 |

Anode Calender |

|

8 |

Cathode Slitting Machine |

|

9 |

Anode Slitting Machine |

|

10 |

Cathode Die Cutting Machine |

|

11 |

Anode Die Cutting Machine |

|

12 |

Auto Stacking Machine |

|

13 |

Hot Press Machine |

|

14 |

Ultrasonic Battery Core Pre Welding Machine |

|

15 |

Ultrasonic Battery Core Welding Machine |

|

16 |

Cover Plate Welding Machine |

|

17 |

Battery Core Film Covering Machine |

|

18 |

Integrated Machine for |

|

19 |

Primary Helium Testing Machine |

|

20 |

High Level Vacuum Oven |

|

21 |

Electrolyte Filling |

|

22 |

Negative Pressure Forming Machine |

|

23 |

Sealing &laser Welding Machine |

|

24 |

Grading Machine |

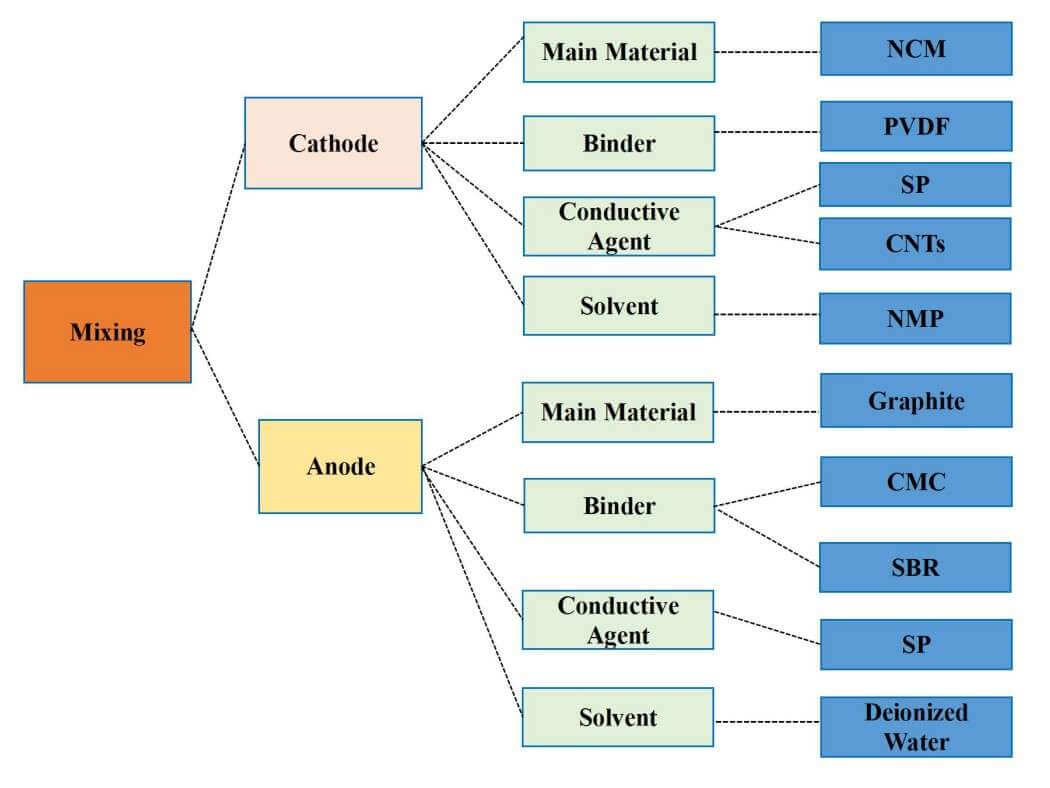

Mixing and coating

News