Casement Window Rubber Seal – Airtight, Durable, Easy Fit

Field Notes on the Casement Window Seal That Actually Works

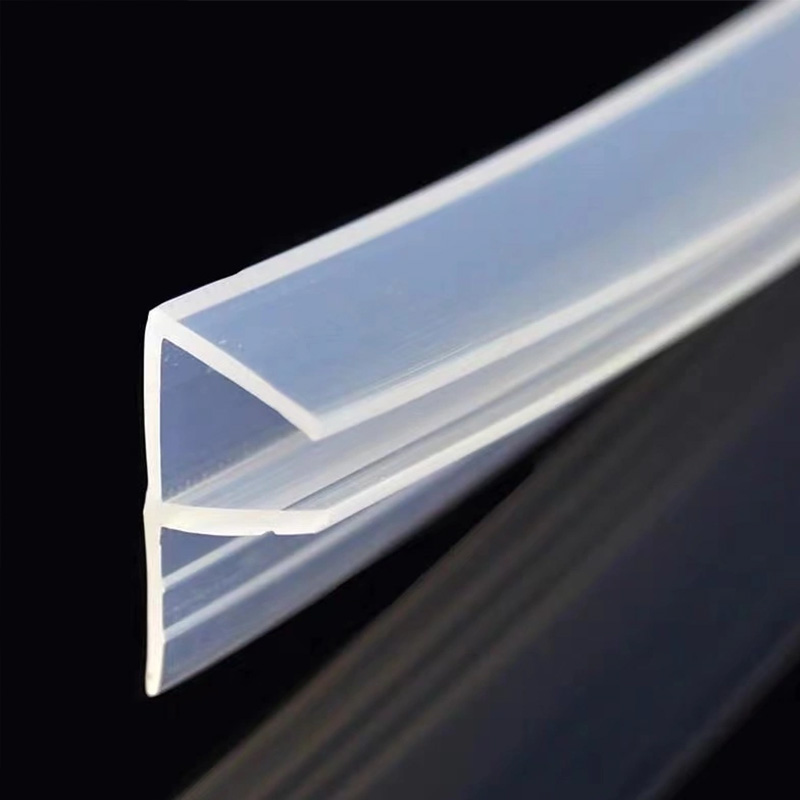

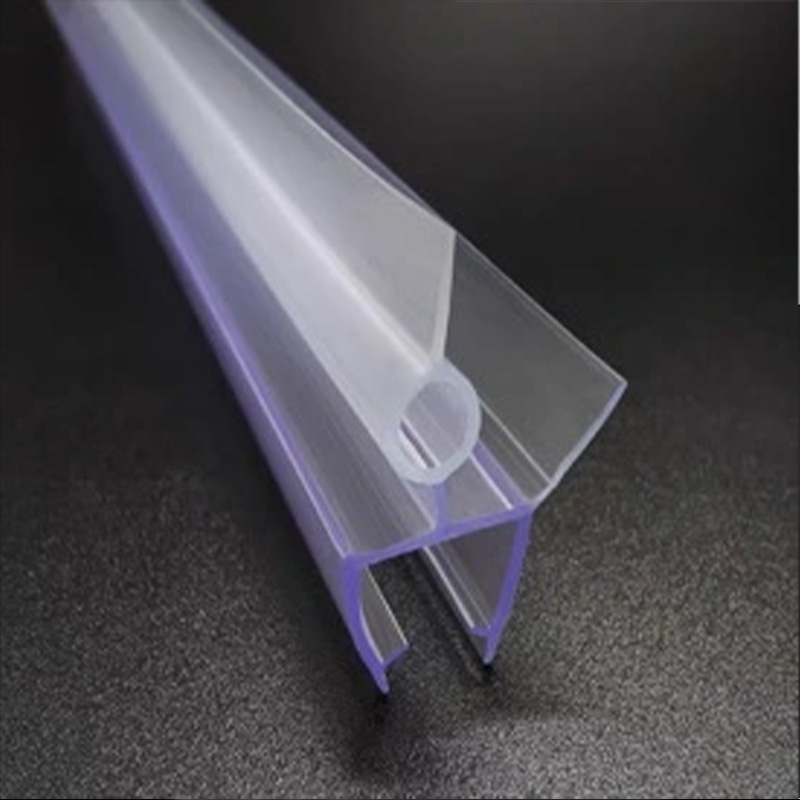

If you’ve chased winter drafts or mysterious whistling around a frame, you already know the unsung hero is the gasket. The workhorse I keep seeing on production floors is the Casement Window Rubber Seal—yes, the same extrusion tech often marketed as “shower door seal strip.” The profiles, compounds, and curing lines are essentially the same. In fact, many customers say they swap profiles across door and window programs without a hitch.

What’s trending (and why it matters)

Code-driven airtightness, quieter urban living, and coastal resilience are pushing window OEMs toward EPDM and TPV blends with better ozone and UV resistance. I’m also seeing low-VOC compounding, color-matched caps, and pre-applied PSA tapes to speed installation. Interestingly, some builders prefer softer durometer tips (to be honest, they seal better on slightly uneven frames).

Practical specs most teams ask for

| Item | Typical Range / Note (real-world use may vary) |

|---|---|

| Materials | NR, EPDM, NBR, SBR, FKM, PP, PVC, TPR/TPE/TPV, TPU, Silicone |

| Durometer | ≈ 45–75 Shore A (ISO 868) |

| Temp range | EPDM −40°C to +120°C; Silicone up to +200°C |

| Compression set | ≈ 20–35% @70°C/22h (ASTM D395) |

| Profiles | Bubble, fin, P-, E-, and co-extruded dual-density tips |

| Color | Black standard; custom colors on request |

| Compliance | RoHS, REACH; weathering per ASTM G154 |

How it’s made (short version)

Materials: compound selection (often EPDM or TPV) tuned for ozone (ASTM D1149) and tensile (ISO 37). Methods: cold-feed extrusion, microwave continuous vulcanization (for EPDM), then cooling, cutting, and corner-vulcanized frames when required. Add-ons: flocking for glide, slip-coats, or PSA tape. Testing: hardness (ISO 868), compression set (ASTM D395), UV exposure (ASTM G154), and air/water ratings at the window assembly level (EN 12207/12208). Service life: ≈ 8–15 years outdoors; coastal installs favor peroxide-cured EPDM or silicone.

Where Casement Window Rubber Seal saves the day

- Residential casements: energy savings via tighter air leakage classes.

- High-rise and coastal projects: wind-driven rain, salt, and UV protection.

- Healthcare/clean manufacturing: dust and acoustic control; low-VOC picks help.

Vendor snapshot (what I’m seeing on quotes)

| Vendor | Strengths | Typical MOQs / Lead | Certs |

|---|---|---|---|

| XT ShuoDing (Xingtai, Hebei; Room 1410, No. 119 Zhongxing East Street) | Wide compound list, custom molds, corner vulcanizing | ≈ 1,000–3,000 m; 10–20 days | RoHS, REACH; in-house QC to ASTM/ISO |

| Generic marketplace seller | Low price, off-the-shelf sizes | Small lots; ship in 2–7 days | Varies; limited test data |

| Local aluminum shop | Fast pickup; frame-to-seal fit advice | By project; immediate to 3 days | Shop-level QA |

Customization that actually helps installers

Sizes by mold to your drawing (tolerances ≈ ±0.3–0.5 mm). Co-extruded soft tips for low latch force. Pre-taped backs for retrofit. Colors: black standard, others on request. If your sash isn’t perfectly true (whose is?), ask for softer nose material and a slightly taller bubble.

Mini case studies

- Midwest hotel retrofit: swapping to Casement Window Rubber Seal with co-extruded fin cut infiltration ≈18% and noise by 6–8 dB, per on-site blower-door and SPL checks.

- Coastal apartments: peroxide-cured EPDM gaskets held compression set under 30% after accelerated UV/ozone cycles; service life projection 12+ years.

Feedback has been surprisingly consistent: installers like the glide of flocked seals, facilities people like fewer callbacks.

Bottom line

If you’re speccing a Casement Window Rubber Seal, prioritize compound, durometer, and verified test data. The “shower door” label is just marketing; the extrusion tech is right for serious window programs.

Authoritative citations

- ASTM D2000: Classification System for Rubber Products in Automotive Applications.

- ISO 868: Plastics and rubber — Shore hardness testing.

- ASTM D395: Standard Test Methods for Rubber Property—Compression Set.

- ASTM D1149: Rubber Deterioration—Cracking in Ozone.

- EN 12207/12208: Windows and doors—Air permeability and Water tightness classification.

- ASTM G154 / ISO 4892: UV weathering of nonmetallic materials.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025