High-Performance Rolling Roller for Industry | Reliable Roller Manufacturer

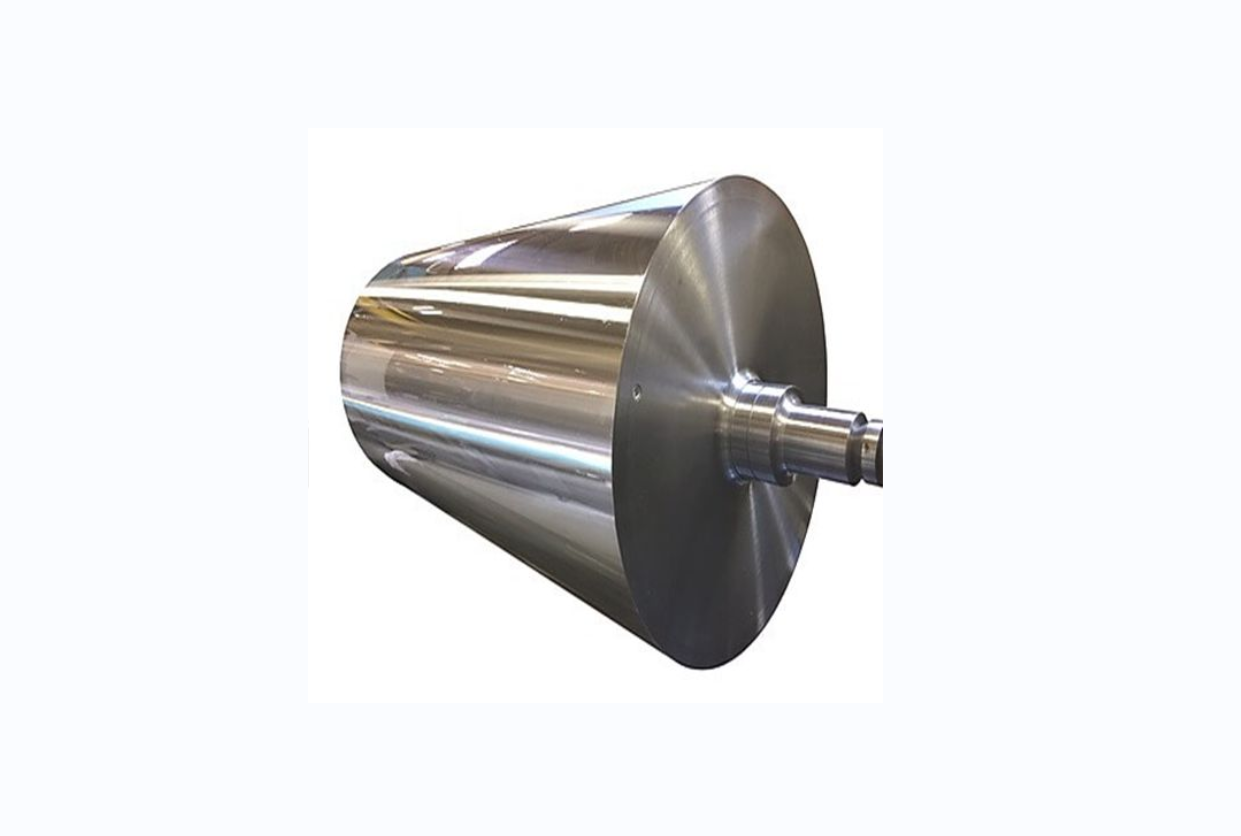

Rolling rollers are pivotal industrial components extensively used in lithium battery production lines, alongside other demanding sectors such as metallurgy, petrochemical, water treatment, and paper manufacturing. As the pursuit of higher efficiency and precision intensifies, rolling roller specification, manufacturing technology, and supplier selection have become critical to competitive advantage. This article delivers a professional, data-driven insight into rolling roller development, technical parameters, process flow, industry benchmarks, customization, and real application cases.

1. Global Industry Trends of Rolling Roller and Applications

In recent years, the rising demand for lithium battery, precision metal forming, and high-purity films has propelled the rolling roller market. According to Grand View Research, the global industrial roller market is valued at over USD 5.8 billion in 2023, with an expected CAGR of 5.2% through 2030, mainly driven by battery, electronics, and green tech sectors.

Key trends include:

- Adoption of harder & wear-resistant alloys like forged steel, tungsten carbide, and special composite materials.

- Implementation of CNC precision machining and automated flaw detection to achieve micron-scale surface tolerances.

- Customization for specific applications: Work rolls for metal, intermediate rolls for processing flexibility, and special anti-corrosive coatings for battery materials.

- Compliance with global manufacturing standards such as ISO 9001:2015, ANSI B65, and GB/T 13312 (China).

- Green and energy-saving requirements — lower friction surfaces, longer service cycles, and sustainable material use.

Application fields: Lithium battery production, non-ferrous metal rolling, steel strip, paper, film, printing, water treatment, and chemical processes.

2. Technical Parameter Table: Rolling Roller vs Other Rollers

| Parameter | Rolling Roller (Lithium Battery) |

Work Rolls (Steel Mill) |

Intermediate Roll (Film) |

|---|---|---|---|

| Material | Cr5 Alloy, 42CrMo, HSS, D2 Tool Steel | Forged Steel, Alloy Steel (9Cr2Mo, 5CrNiMo) | Composite Steel, Stainless, Polyurethane Shell |

| Hardness (HRC) | 61-66 | 58-65 | 35-55 |

| Surface Precision | Ra0.02~0.1μm | Ra0.1~0.25μm | Ra0.2~0.4μm |

| Diameter Range | 60–360mm | 200–650mm | 60–250mm |

| Length (Max) | 2200mm | 3800mm | 1800mm |

| Lifespan | 30,000–70,000 running hours | 15,000–35,000 running hours | 10,000–20,000 running hours |

| Certification | ISO 9001, SGS, ANSI B65 | ISO 9001, EN10204 | FDA, ISO 9001 |

| Main Application | Lithium battery electrode/foil calendering | Hot & cold rolling of steel plates, bars | Film, foil, flexible web |

3. Rolling Roller Manufacturing Process & Key Technologies

The rolling roller production process reflects the synergy of advanced materials, high-precision machining, strict quality detection, and robust anti-corrosion strategies, particularly for lithium battery lines where purity and durability are crucial.

Standards: ISO 9001:2015 (Quality), ANSI B65, SGS.

Process: Forging/Casting → CNC Turning & Grinding → Surface Polishing → Surface Coating/Plating → Ultrasonic/UT/MT Inspection → Final Packaging.

- Ingot Preparation: High-purity steel/Cr-alloy preparation, chemical composition control.

- Forging/Casting: Controlled forging/casting for grain refinement and crack resistance.

- Rough Machining: Heavy CNC turning, end face & center hole machining.

- Heat Treatment: Quenching (850–880°C), tempering for target hardness and residual stress relief.

- Precision Grinding & Turning: CNC cylindrical & surface grinding to required diameter and

Ra0.02μmfinish. - Surface Treatment: Electroplating (chrome, Ni-P), oxidation, or ceramic spraying for corrosion/wear protection.

- Nondestructive Testing: Ultrasonic, magnetic particle (UT/MT) for internal & surface flaw detection (ISO/ASTM/GB).

- Final Assembly & Packing: Tolerance verification, dynamic balancing, ISO/SGS certified FINAL QA.

(Forging ➔ Machining ➔ Precision Grinding ➔ Coating ➔ Test ➔ Packing)

Common Parameters & Industry Benchmarks

| Parameter | Value / Range | Standard |

|---|---|---|

| Hardness | 61–66 HRC | GB/T 13312, ASTM A388/A370 |

| Surface Finish (Ra) | ≤0.02μm (after precision grind) | EN10204, China JB/T 820-2015 |

| Roundness/Runout | ≤0.01mm | ISO 1101 |

| Bearing Journal Tolerance | IT6–IT7 | ISO 286 |

| Surface Coating Adhesion | ≥12N/mm2 | ISO 2409:2020 |

| Defect Size (UT/MT) | ≤0.5mm (none critical allowed) | ASTM E45/GB/T 13298 |

4. Rolling Roller Manufacturer & Supplier Comparison 2024

| Company/Supplier | Country | Main Product | Certifications | Annual Output (Units) |

Lead Time |

|---|---|---|---|---|---|

| XTSHUODING | China | Rolling roller (Lithium battery, high-precision) | ISO 9001, SGS | 30,000 | 2-4 weeks |

| German RollerWorks | Germany | Calender, industrial rollers | ISO 9001, TUV | 7,200 | 4-6 weeks |

| MHI (Japan) | Japan | Steel mill, paper roll, work rolls | ISO 14001, JIS | 13,000 | 4-8 weeks |

| Valmet | Finland | Paper, tissue, foil | ISO 9001 | 6,500 | 3-6 weeks |

| Zhejiang Wanli | China | Polyurethane, rubber roller | ISO 9001 | 15,000 | 2-5 weeks |

5. Customization, Delivery and Quality Assurance

- Specification Online Selection: Select diameter (Φ60–350mm), length (300–2200mm), and mounting standard per line layout.

- Material Option: Hardened steel (60–66 HRC), D2, Cr5, or corrosion-resistant coat for battery/electronic sector.

- Precision Customization: Achieve Ra0.02μm, concentricity ≤0.01mm, especially for thin film/electrode.

- Coating/Surface Options: Chrome, nickel-phosphorus, ceramic, or glass for enhanced durability, adhesion, and anti-static.

- Dynamic Balancing: All rollers undergo G2.5 balancing (ISO 1940) for high-speed lines (>100 m/min).

- Fast Production Cycle: 18–30 days (standard), urgent project option: 12–15 days.

- Warranty & Service: 24+ months or ≥30,000 operating hours, technical support, global express logistics.

6. Real Application Cases & Performance Analysis

Challenge: Original imported rollers failed after 6–8 months, surface microcracks and high downtime.

Solution: Custom rolling roller (Cr5, Ra0.025μm, ceramic coat, balanced at 10,000 rpm)

Results (2023 data):

- Roller average lifespan: 2.5 years (↑ 230% improvement)

- Surface roughness maintained: Ra0.028μm after 60,000 hrs

- Cost per 10,000 hrs in use: ↓38%

- Zero downtime attributed to roller defects for 22 months

Challenge: Environmental corrosion and chemical pitting on standard rollers.

Solution: Rolling roller (Ni-P coating, advanced sealing, ISO 2409 adhesion) supplied and certified.

Results:

- Zero visible corrosion, even after 1,500 hours salt spray exposure

- Uninterrupted operation under weekly acidic wash cycles

- Validated by third-party SGS test report (downloadable upon request)

Frequently Asked Technical Questions about Rolling Roller

- 1. What material is best for a rolling roller in lithium battery lines?

- 42CrMo or Cr5 alloy steel is recommended due to its superior hardness (up to 66HRC), wear and corrosion resistance, and consistent microstructure. For chemical-heavy lines, Nickel-Phosphorus (Ni-P) or full ceramic coatings further boost durability.

- 2. What surface finish is optimal for electrode calendering?

- Ultra-smooth Ra0.02–0.04μm is standard, achieved by high-precision CNC grinding and lapping, minimizing electrode wrinkling/façade defects.

- 3. How to ensure roller dimensional precision?

- High-end roller manufacturers implement CNC measurement and real-time feedback loops, resulting in roundness ≤0.01mm and bearing journal tolerance up to IT6–IT7, per ISO286/1101.

- 4. What standards apply for defect testing?

- Ultrasonic (UT) and magnetic (MT) tests are conducted per ASTM E45, EN10228, and GB/T 13312, ensuring no critical subsurface cracks or inclusions.

- 5. Can rolling roller be used in chemical/petrochemical industries?

- Yes. Applying Ni-P or ceramic composite coatings achieves ideal anti-corrosion, with proven performance in acidic and humid environments (see SGS salt spray test).

- 6. What is the expected delivery cycle?

- Standard lead time is 18–30 days, with customizable rapid delivery as short as 7–12 working days for essential spare parts.

- 7. What about after-sales and warranty?

- Full 24–36-month warranty (or ≥30,000 operating hours), rapid onsite troubleshooting (including overseas), and lifespan monitoring with regular inspection advice.

8. Order, Delivery, and Support

- Inquiry & Consultation: Experts available 7x24 to answer application and fitting queries;

- Specification Confirmation: Technical team reviews and recommends best rolling roller type for your line;

- Sample & Batch Production: Material certification, CNC path files provided for traceability; pilot/sample option available;

- Factory Acceptance: Dual inspection (customer & third-party e.g. SGS) for hardness, roundness, and surface quality;

- Shipping: Secure packaging (vacuum/anti-oxidation), global express/sea/air logistics included;

- After-sales Guarantee: Free technical support, real-time replacement, and performance monitoring via QR code track/report.

9. References, Standards, and Further Reading

- Grand View Research: Global Industrial Roller Market Report

- Battery Community Forum: Best Practices of Roller for Lithium Battery Lines

- ISO 9001:2015 - Quality Management, www.iso.org

- SGS Test Standards for Rollers: SGS Industrial Manufacturing Test

- ASTM E45: Standard Test Methods for Inclusion Content of Steel; ASTM Official

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025