High-Quality D Type Rubber Door Seal for Superior Draft Protection

by XINGTAI SHUODING TRADING CO.,LTD

Website: https://www.xtshuoding.com

Email: sdtrading0927@126.com

Phone: 86-19803295498

Address: Room 1410, No. 119 Zhongxing East Street, Xiangdu District, Xingtai City, Hebei Province, China.

As building performance requirements and industrial standards evolve, the global demand for d type rubber door seal and related sealing solutions such as d type rubber seal, door edge rubber seal, door frame rubber seal, and door frame rubber seal strip continues to rise sharply. Whether in modern architecture, cold chain logistics, automobile manufacturing, or high-end appliance industries, reliable sealing is mission-critical to prevent noise, dust, water, and air infiltration.

As a leading manufacturer and exporter headquartered in Xingtai—China’s “Seal Production Base”—XINGTAI SHUODING TRADING CO.,LTD delivers highly customized engineering solutions using state-of-the-art elastomer technologies, surpassing global standards in reliability and energy efficiency.

- Superior Air & Water Tightness: The unique “D” profile effectively sealed gaps, providing advanced sound, water, and wind insulation biomass (see research: Journal of Building Performance).

- Durability & Chemical Resistance: Top-grade synthetic and natural rubbers resist ozone, UV, oils, and aging—ideal for extreme temperature fluctuation zones.

- User-Friendly Installation: Flexible structure supports tool-free DIY fitment for doors, industrial machines, autos, and appliances.

- Noise Reduction: Certified to absorb up to 40dB noise (per IAPMO research forum), improving comfort.

- Eco-friendly Choices: Growing market for silicone, EVA, and CR blends reduces the use of environmentally hazardous plastics.

| Parameter | Typical Value / Range | Test Standard |

|---|---|---|

| Material Options | EPDM / Silicone / NBR / EVA / CR | ASTM D2000 |

| Density | 0.8–1.2 g/cm³ | ISO 2781 |

| Hardness (Shore A) | 50 ±5 | ASTM D2240 |

| Tensile Strength | 7–14 MPa | ASTM D412 |

| Compression Set | <35% (24h/70°C) | ASTM D395 |

| Operating Temp. | -50°C to +120°C (Silicone: up to 220°C) | ASTM D573 |

| Color Range | Black, Grey, White, Customized | Customer Spec. |

| Fire Rating | UL94 V-0/V-1 on Request | UL94 |

| Adhesive Backing | Acrylic / Hot-melt / Custom | ISO 29862 |

- Smart Upgrade: Integration with IoT sensors for real-time monitoring of door seal integrity (Source: Smart Building Magazine).

- Sustainability: Demand surges for recyclable materials like Silicone EVA CR blends, drastically reducing carbon footprint.

- Precision Manufacturing: Rapid adoption of CNC-based extrusion lines achieves micron-level consistency, optimizing air-seal performance.

- Multi-Functional Seals: New formulations offer combined benefits: anti-microbial, odor-neutralizing, and thermal-stabilizing.

- Industrial Doors & Windows: Large-scale machinery, cleanrooms, and workshops rely on robust sealing to prevent dust ingress and optimize HVAC performance.

- Residential Buildings: Seals in homes/apartments, for noise absorption and energy conservation at door frames, window sashes, and sliding doors.

- Cold Chain Logistics: Truck container111s, chillers, and walk-in freezers use d type rubber door seal for “thermal hermeticity”—key to goods freshness.

- Automotive: Modern vehicles use them for doors, trunks, engine bays, sunroofs—ensuring dust, water, vibration, and air noise isolation.

- Electrical Enclosures: Switchgear, automation cabinets, and electronic housings are protected from airborne particles and moisture.

- Appliances: Ensuring energy efficiency for air conditioners, refrigerators, and smart appliances.

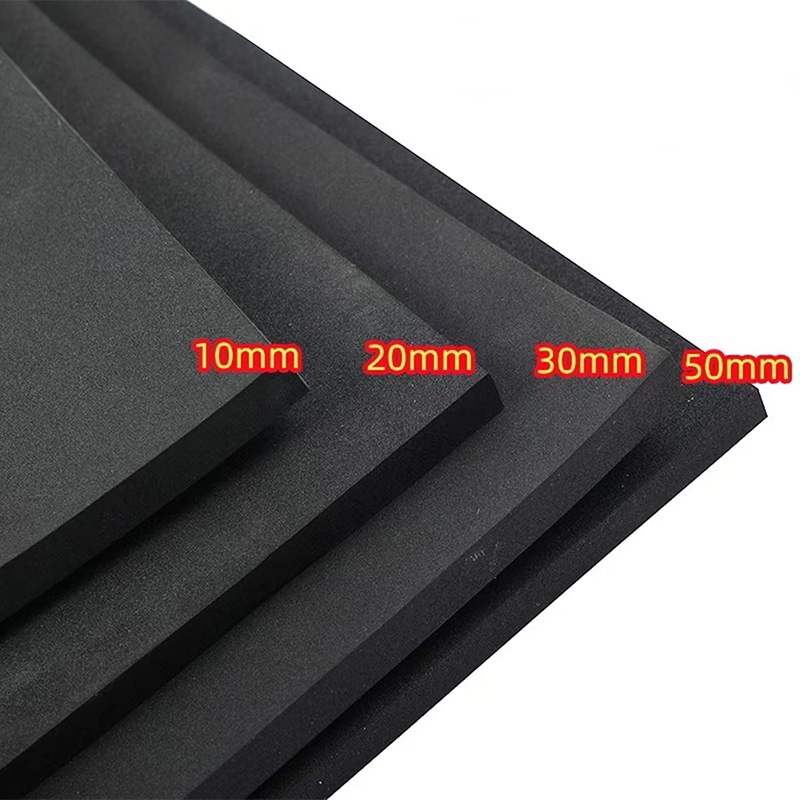

Product Link: https://www.xtshuoding.com/silicone-eva-cr-rubber-foam-sheet.html

Product Profile:

1. EVA foam plays the role of refrigeration and freezing in automobiles, air conditioners, refrigerators, freezers, and household appliances.

2. Skates and sports shoes can employ colorful EVA, such as sports insoles, luggage back pads, surfboards, kneeling pads, yoga mats.

3. EVA foam acts as insulation in cold-proof buildings, ice storage, light roofing, and other construction installations.

| Year | Global Demand (in million meters) | Average Price (USD/meter) | Energy Conservation Standard (R-value, m2·K/W) |

|---|---|---|---|

| 2018 | 158 | 0.53 | 0.95 |

| 2019 | 167 | 0.56 | 1.10 |

| 2020 | 181 | 0.59 | 1.20 |

| 2021 | 197 | 0.62 | 1.28 |

| 2022 | 211 | 0.66 | 1.39 |

| 2023 | 236 | 0.70 | 1.47 |

Q1: What are the main materials used in d type rubber door seals?

d type rubber door seal can be produced using EPDM, Silicone, EVA, CR (chloroprene), NBR, and Natural Rubber. EPDM offers top-notch weather, ozone, and UV resistance, while Silicone excels in high-temperature performance. EVA and CR blend foam improve insulation and environmental compliance.

Q2: Which specifications are critical for selecting door edge rubber seal?

Core specifications include hardness (40-65 Shore A varies by door gap), density, compression set (<35%), tensile strength (>7MPa), and compatibility with paints or adhesives. UL94 fire resistance may be required for high-safety areas.

Q3: How is a door frame rubber seal strip installed for optimal seal?

Measure the gap, cut the strip (add +2% length), clean surface with isopropyl alcohol, peel the release liner, and firmly apply (with slight compression). Avoid stretching during installation for longevity.

Q4: Are d type rubber seals suitable for both exterior and interior doors?

Yes, owing to their advanced weather and chemical resistance, d type rubber seal can be used on exterior entryways, garage doors, and interior partitions in commercial, residential, and industrial settings.

Q5: What certifications do high-end door frame rubber seals meet?

They may be certified per UL 94 (fire resistance), ASTM for aging/chemical resistance, and RoHS/REACH for environmental safety. Contact us for technical sheets!

Q6: Can d type rubber door seal be custom colored and shaped?

Absolutely. XINGTAI SHUODING TRADING CO.,LTD supports customized color (black, grey, beige, red, transparent, etc.) and cross-sectional profiles to suit unique architectural/industrial requirements.

Q7: How do I choose between silicone EVA CR foam sheet and conventional rubber foam for insulation?

Silicone EVA CR rubber foam sheet delivers superior insulation, lower water absorption, and wider operating temperature. It’s highly recommended for cold chain, energy-efficient buildings, and food-grade applications compared to basic NBR or EPDM foams.

- Decades of R&D expertise focused on d type rubber door seal, d type rubber seal, door edge rubber seal, and door frame rubber seal strip.

- Certified factory—ISO9001, SGS, and RoHS compliance.

- OEM/ODM capability for worldwide architectural and industrial customers.

- 100% sample and batch traceability—strictest QA and batch control.

- Global fast shipping and responsive engineering support.

- Free consultation: sdtrading0927@126.com | +86-19803295498

Contact us for technical inquiry, sample customization, or to explore our full product line at our product page.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025