Innovations in Battery Assembly: The Future of Energy Storage

As the world moves toward more sustainable energy solutions, the demand for efficient and high-quality battery manufacturing equipment is surging. From lithium ion battery assembly machines to lead acid battery production lines, the manufacturing process of batteries is evolving rapidly. Battery assembly line manufacturers are innovating to meet the growing global need for advanced energy storage technologies. In this article, we will explore the various types of equipment involved in battery production and highlight the importance of lithium cell machinery and equipment for lithium battery assembly in the manufacturing process.

Lithium Ion Battery Assembly Machine: The Backbone of Modern Energy Storage

I lithium ion battery assembly machine plays a pivotal role in the production of lithium-ion batteries, which are widely used in electric vehicles (EVs), portable electronics, and renewable energy storage systems. This machine is designed to efficiently and precisely assemble the various components of a lithium-ion battery, ensuring high performance and safety standards.

In the manufacturing process, the lithium ion battery assembly machine automates the critical tasks of cell stacking, electrode placement, electrolyte filling, and sealing. The machine ensures that each battery is assembled with precision, reducing the risk of defects and improving the overall quality of the battery. Advanced features such as real-time monitoring, temperature control, and pressure adjustment are incorporated into these machines to ensure optimal battery performance.

The global shift toward electric vehicles (EVs) and renewable energy systems has driven the demand for lithium ion battery assembly machines. As more industries rely on lithium-ion technology, the need for sophisticated, high-efficiency machines to handle the production scale and complexity is critical. Investing in top-tier lithium ion battery assembly machines can help manufacturers meet these growing demands while ensuring the production of reliable and long-lasting batteries.

Lead Acid Battery Production Line: Essential for Traditional Energy Storage

Despite the rise of newer technologies like lithium-ion batteries, the lead acid battery production line remains a crucial part of the energy storage industry. These batteries are widely used in automotive, backup power systems, and industrial applications due to their affordability and reliability. The lead acid battery production line is specialized equipment designed to manufacture lead acid batteries at scale, ensuring consistency and quality in every battery produced.

I lead acid battery production line involves several key steps: electrode manufacturing, plate assembly, cell formation, and battery testing. Modern lead acid battery production lines are equipped with automation systems to streamline each step of the process. These lines are designed for high-speed, high-volume production, which is necessary to meet the ongoing demand for affordable energy storage solutions in the automotive and telecommunications sectors.

Manufacturers of lead acid battery production lines must focus on improving efficiency and safety during production, as lead and acid handling can be hazardous. Innovations in automation, environmental control systems, and energy-efficient technologies are making modern lead acid battery production lines safer, more sustainable, and cost-effective. Despite the growth of lithium-based technologies, lead acid batteries continue to be a popular choice for many applications due to their affordability and reliable performance.

Equipment for Lithium Battery Assembly: Precision Meets Innovation

As the demand for lithium-ion batteries grows, so does the need for equipment for lithium battery assembly. This equipment is essential for ensuring the high-quality production of batteries used in everything from smartphones to electric vehicles. Equipment for lithium battery assembly encompasses a range of specialized tools and machinery, including tab welding machines, cell handling systems, and vacuum sealing units, all of which are necessary for the precise and efficient assembly of lithium batteries.

The assembly process involves several critical stages, such as electrode winding, electrolyte filling, and battery cell formation. Equipment for lithium battery assembly ensures that each step is performed with the utmost accuracy, reducing the risk of faults or defects. As lithium battery technology advances, the machinery involved in its assembly becomes more sophisticated, integrating real-time diagnostics, smart controls, and automation features to increase production speeds and improve overall battery performance.

Manufacturers looking to remain competitive in the lithium battery market must invest in the latest equipment for lithium battery assembly. As consumer and industrial demand for more powerful, efficient, and longer-lasting batteries increases, so does the need for advanced machinery that can meet these expectations. The right equipment for lithium battery assembly is a crucial element for any company hoping to thrive in the fast-paced energy storage industry.

Battery Assembly Line Manufacturers: Innovating for Efficiency and Scalability

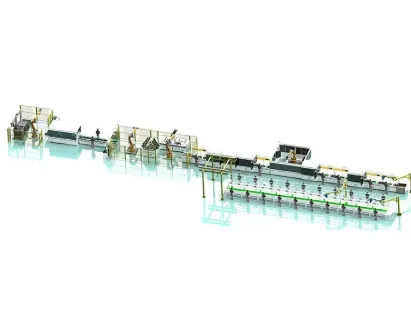

Battery assembly line manufacturers are at the forefront of the battery production revolution, developing cutting-edge technologies that streamline the manufacturing process. These manufacturers provide the tools and equipment necessary to build high-quality batteries at scale. With the rise of electric vehicles, renewable energy storage, and portable electronics, battery assembly lines need to be adaptable, scalable, and efficient to meet global demand.

Battery assembly line manufacturers offer a range of solutions, from fully automated systems to semi-automated solutions that allow for more flexibility in production. These lines incorporate advanced robotics, real-time data collection, and AI-powered controls to ensure that production is optimized for speed, efficiency, and quality. Battery assembly line manufacturers are also focusing on reducing energy consumption and waste during the manufacturing process, making their products more sustainable and cost-effective.

The success of any battery manufacturer relies on the ability to create efficient and reliable assembly lines that can scale to meet growing demand. By partnering with leading battery assembly line manufacturers, businesses can leverage the latest technology to enhance production capacity, reduce operational costs, and improve battery quality. As the market for batteries continues to expand, the role of battery assembly line manufacturers becomes even more critical in shaping the future of energy storage.

Lithium Cell Machinery: The Core of Battery Production

Lithium cell machinery is the specialized equipment used to produce the core cells of lithium-ion batteries. These cells are the building blocks of all lithium-ion-based energy storage systems, and their production requires precision and quality control at every stage. From electrode preparation to cell assembly, lithium cell machinery ensures that each cell meets the necessary performance standards for capacity, voltage, and cycle life.

Advanced lithium cell machinery incorporates features like automated cell insertion, electrolyte filling, and sealing to improve production efficiency and reduce the risk of human error. These machines are also equipped with sensors and monitoring systems to ensure that each cell is tested for quality before it is incorporated into a battery pack. With the growing demand for lithium-ion batteries in everything from smartphones to electric vehicles, the role of lithium cell machinery in the production process cannot be overstated.

The demand for high-performance lithium-ion batteries has led to rapid advancements in lithium cell machinery. Manufacturers are investing in next-generation machinery that can produce cells with higher energy density, faster charging times, and longer lifespans. For businesses looking to stay ahead of the competition, investing in cutting-edge lithium cell machinery is crucial for ensuring the continued growth and success of their battery production operations.

The growing demand for advanced energy storage solutions has led to significant advancements in battery manufacturing technologies. From lithium ion battery assembly machines to lead acid battery production lines, equipment for lithium battery assembly, battery assembly line manufacturers, and lithium cell machinery, each element of the production process plays a critical role in ensuring the quality and efficiency of modern batteries. As the global shift toward renewable energy sources and electric vehicles continues, these technologies will become even more essential in meeting the rising demand for reliable, high-performance batteries.

Manufacturers that invest in the latest battery assembly equipment will be well-positioned to capitalize on the growing market for energy storage solutions. With advancements in automation, precision, and sustainability, the future of battery production looks brighter than ever, offering opportunities for innovation and growth in the rapidly expanding energy sector.

Yabelana

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeIindabaNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseIindabaNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyIindabaNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseIindabaNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileIindabaNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedIindabaNov.10,2025