Leading Lithium Ion Battery Assembly Machine Providers

The rapid expansion of electric vehicles, portable electronics, and renewable energy storage has placed the lithium ion battery assembly machine at the heart of global manufacturing growth. These highly specialized machines are designed to produce batteries with the highest precision, ensuring consistent performance, safety, and efficiency. A state-of-the-art lithium ion battery assembly machine automates critical processes such as electrode stacking, cell sealing, electrolyte injection, and formation cycling. This level of automation significantly reduces human error, increases production speed, and improves overall battery quality.

In modern factories, a lithium ion battery assembly machine integrates intelligent control systems, real-time monitoring, and precision calibration tools. These ensure that every battery cell meets stringent performance standards before it reaches the market. As battery demand grows across industries, manufacturers are turning to suppliers who can provide machines that adapt to evolving chemistries, such as high-nickel cathodes and silicon-anode technologies. By investing in advanced machinery, companies not only enhance production efficiency but also extend the lifespan, safety, and energy density of their battery products.

The Role of Top Battery Assembly Line Manufacturers in Global Energy Supply

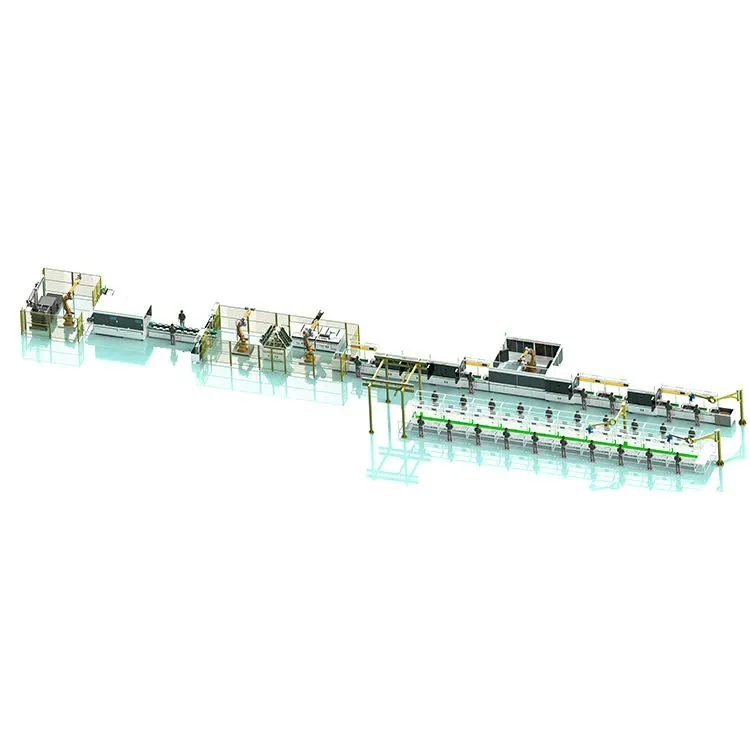

Beyond individual machines, entire production ecosystems are managed by leading battery assembly line manufacturers. These companies design, build, and install fully integrated lines that can produce millions of cells per year. Their expertise extends to layout planning, automation integration, and quality assurance systems. By partnering with experienced battery assembly line manufacturers, businesses gain access to turnkey solutions that streamline operations from electrode preparation to final packaging.

The most respected battery assembly line manufacturers work closely with clients to customize line configurations according to capacity requirements, product types, and facility constraints. They also ensure seamless integration with upstream and downstream processes, such as electrode coating machines and module assembly stations. Furthermore, these manufacturers often provide after-sales services, including training, maintenance, and software updates. As global energy storage markets become increasingly competitive, choosing a reliable battery assembly line manufacturer can make the difference between maintaining market leadership and falling behind.

High-Performance Lithium Battery Equipment for Every Production Stage

While the lithium ion battery assembly machine is crucial for the core assembly process, broader lithium battery equipment is needed to support the entire manufacturing chain. This includes electrode mixers, coating and drying systems, calendaring machines, slitting units, winding or stacking machines, electrolyte filling stations, and formation testing equipment. Each piece of lithium battery equipment plays a unique role in ensuring battery performance, consistency, and safety.

Advanced lithium battery equipment is engineered to operate under cleanroom conditions, minimizing contamination risks that could compromise battery reliability. For example, precision electrode coating machines ensure uniform thickness across large batches, while high-speed winding machines maintain perfect alignment to prevent internal short circuits. Manufacturers who invest in premium lithium battery equipment benefit from reduced scrap rates, higher output quality, and greater flexibility to adapt to new cell formats such as pouch, cylindrical, and prismatic designs. The integration of AI-driven analytics also allows operators to detect anomalies in real time, preventing costly defects and ensuring compliance with industry standards.

Why Combining Lithium Ion Battery Assembly Machine, Battery Assembly Line Manufacturers, and Lithium Battery Equipment Brings Competitive Advantage

A holistic approach to battery production involves sourcing from the best lithium ion battery assembly machine providers, working with experienced battery assembly line manufacturers, and investing in top-tier lithium battery equipment. When these three elements align, companies can achieve unmatched production efficiency, scalability, and quality. This integrated strategy eliminates compatibility issues between different equipment, reduces downtime, and ensures that every stage of production works in harmony.

For example, a startup launching an EV battery plant might acquire a complete assembly line from a reputable battery assembly line manufacturer, equipped with advanced lithium ion battery assembly machines for precision tasks and supported by specialized lithium battery equipment for coating, calendaring, and testing. This synergy enables faster time-to-market, reduced operational risks, and higher return on investment. Additionally, working with suppliers who understand the full production chain allows businesses to quickly scale capacity as market demand increases.

Future Trends in Lithium Ion Battery Assembly Machine, Battery Assembly Line Manufacturers, and Lithium Battery Equipment

The battery manufacturing industry is evolving at an unprecedented pace, driven by the push toward carbon neutrality and technological breakthroughs. Lithium ion battery assembly machine designs are moving toward even higher precision, with advanced robotics and AI integration to detect microscopic defects. Meanwhile, battery assembly line manufacturers are creating modular, flexible production lines that can be quickly reconfigured to handle next-generation chemistries such as solid-state batteries.

Similarly, lithium battery equipment is becoming smarter, more energy-efficient, and more sustainable. For example, advanced drying systems now recycle heat to reduce energy consumption, while formation equipment uses optimized charge/discharge cycles to extend battery lifespan. In the future, we can expect a stronger emphasis on green manufacturing practices, where waste materials are recycled back into the production process, and carbon emissions are tracked and minimized at every stage. Manufacturers that adopt these forward-looking solutions will be well-positioned to meet rising global demand while adhering to stricter environmental regulations.

lithium ion battery assembly machine FAQs

What is the function of a lithium ion battery assembly machine?

A lithium ion battery assembly machine automates key steps in battery cell manufacturing, including electrode stacking, electrolyte filling, sealing, and formation. Its goal is to improve production efficiency, ensure product consistency, and maintain high safety standards.

How do battery assembly line manufacturers support large-scale production?

Battery assembly line manufacturers design and install complete production lines that integrate multiple machines and processes. They ensure seamless workflow, optimize space utilization, and provide maintenance and training services to keep operations running efficiently.

What types of lithium battery equipment are essential for manufacturing?

Essential lithium battery equipment includes electrode mixers, coating and drying machines, slitting units, winding/stacking machines, electrolyte filling systems, and formation testers. Each plays a critical role in producing high-quality, reliable battery cells.

Can a production line handle both cylindrical and pouch cells?

Yes, many modern lines from leading battery assembly line manufacturers are designed for flexibility, allowing quick reconfiguration to produce different cell types such as cylindrical, pouch, or prismatic, depending on market demand.

What factors should be considered when selecting lithium battery equipment?

Key factors include production capacity, precision, compatibility with existing systems, ease of maintenance, energy efficiency, and supplier reputation. Choosing the right lithium battery equipment ensures long-term performance and cost savings.

Yabelana

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeIindabaNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseIindabaNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyIindabaNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseIindabaNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileIindabaNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedIindabaNov.10,2025