High-Performance Battery Production Equipment & Solutions

The Core of Modern Energy: Understanding Battery Production Equipment

The global energy transition is accelerating, driven by the surging demand for electric vehicles (EVs), renewable energy integration, and grid-scale energy storage solutions. At the heart of this revolution lies the sophisticated machinery responsible for manufacturing advanced batteries. This article delves into the intricacies of battery production equipment, exploring its vital role, technical specifications, application breadth, and the cutting-edge innovations driving the industry forward. We aim to provide B2B decision-makers and engineers with a comprehensive overview of the essential tools enabling the future of energy.

Navigating Industry Trends in Battery Manufacturing

The battery industry is experiencing unprecedented growth. Reports indicate that the global lithium-ion battery market is projected to reach over $180 billion by 2030, with a Compound Annual Growth Rate (CAGR) exceeding 15%. This growth is fueled by stringent emissions regulations, advancements in battery technology, and increasing consumer adoption of EVs. Key trends impacting battery production equipment include:

- Increased Automation and AI Integration: To enhance precision, throughput, and reduce human error in lithium battery manufacturing machine operations.

- Focus on Sustainability: Demand for equipment that supports greener manufacturing processes, reduces waste, and optimizes energy consumption.

- Scalability and Modularity: Enabling manufacturers to quickly adapt to market demands and expand production capacity efficiently.

- Advanced Material Handling: Equipment capable of precisely handling new anode and cathode materials, solid-state electrolytes, and other next-generation components.

- Enhanced Quality Control: Integration of advanced in-line inspection systems, machine vision, and data analytics to ensure high-quality output and minimize defects.

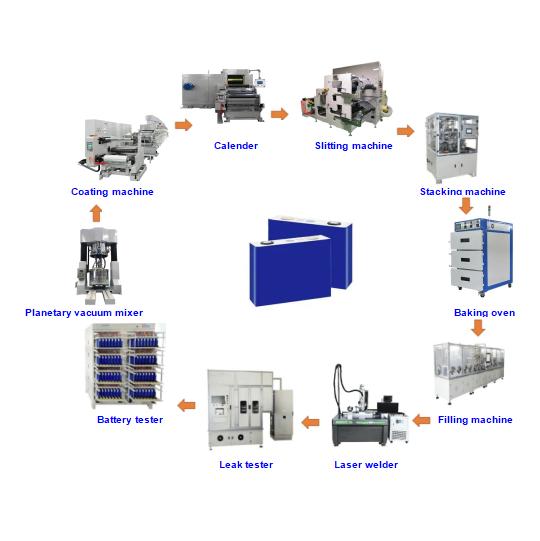

Figure 1: Automated battery production equipment line for enhanced efficiency.

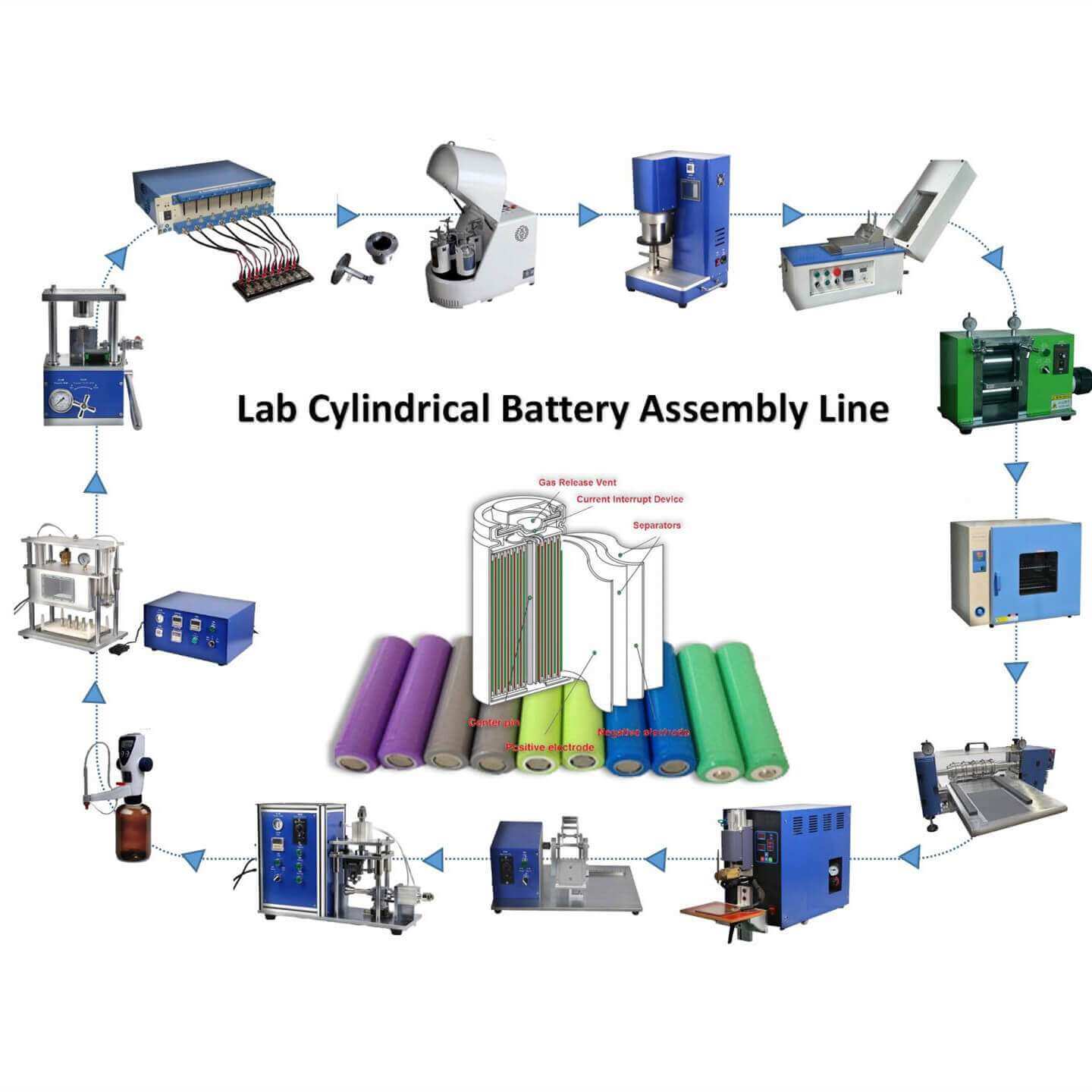

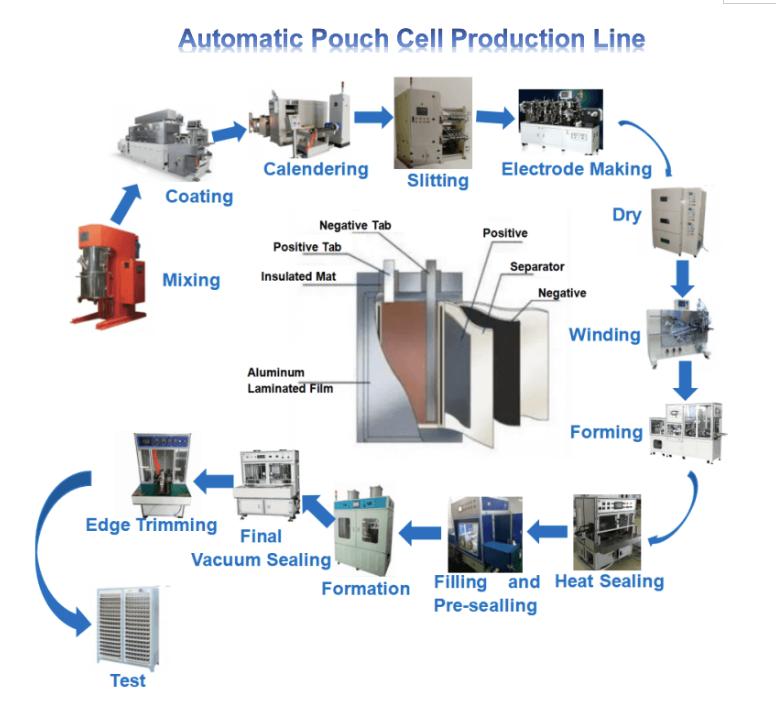

Detailed Process Flow: From Raw Material to Finished Cell

The manufacturing of lithium-ion batteries is a complex, multi-stage process that relies on highly specialized battery production equipment. Each stage demands precision, control, and adherence to rigorous quality standards.

-

Electrode Preparation:

This initial phase involves preparing the anode and cathode materials. Active materials (e.g., NMC, LFP for cathode; graphite, silicon for anode), conductive additives, and binders are precisely mixed in slurry preparation equipment. This slurry is then coated onto metal foil current collectors (aluminum for cathode, copper for anode) using high-precision coating machines. The coated foils are subsequently dried and then calendered (pressed) to achieve desired thickness and density, crucial for energy density and power output. Manufacturing processes involve advanced mixing, precision coating, and high-pressure calendering.

-

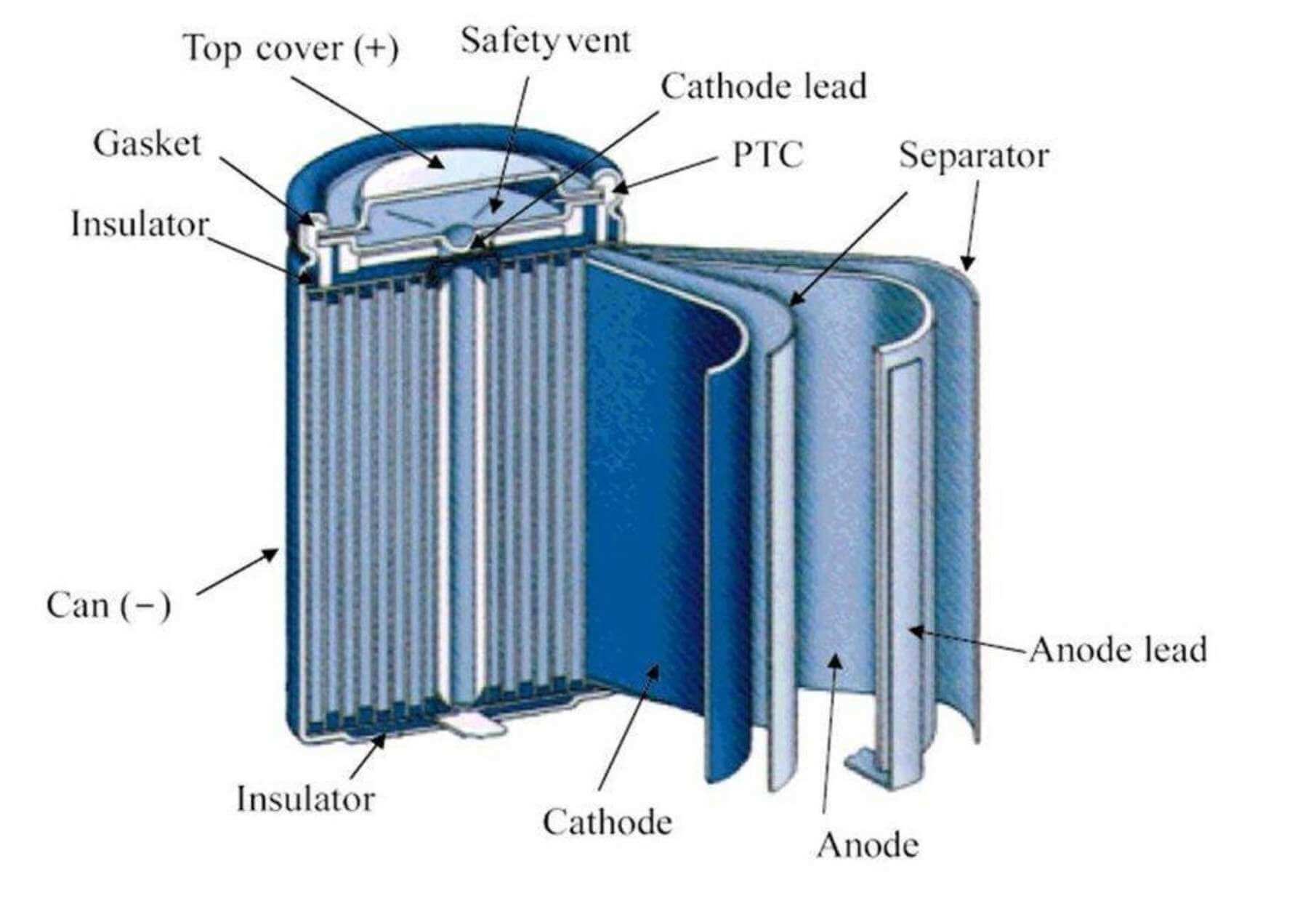

Cell Assembly:

Following electrode preparation, the coated foils are cut into specific dimensions using slitting machines. These cut electrodes, along with a separator (a microporous membrane preventing short circuits), are then assembled into cell units. Depending on the cell format (cylindrical, prismatic, pouch), this involves winding (for cylindrical) or stacking (for prismatic/pouch) equipment. Automated welding processes (e.g., ultrasonic or laser welding) connect the tabs, followed by packaging in a suitable casing. Quality control at this stage often involves non-destructive testing and visual inspection for defects.

-

Electrolyte Filling and Sealing:

The assembled cell is then filled with electrolyte, a crucial step requiring precise volumetric control in a dry room environment. Specialized electrolyte filling machines ensure even distribution and prevent contamination. After filling, the cells are hermetically sealed using laser welding or heat sealing equipment, preventing moisture ingress and electrolyte leakage, both critical for long-term cell performance and safety. Adherence to ISO 13485 (relevant for manufacturing quality control for complex products) principles is often applied here.

-

Formation and Aging:

This is a critical conditioning phase, performed by battery formation equipment. During formation, the battery undergoes initial charge and discharge cycles under controlled conditions. This process forms the Solid Electrolyte Interphase (SEI) layer on the anode, which is essential for stable cell operation and long cycle life. After formation, cells undergo an aging period (several days to weeks) to stabilize and identify potential defects before shipment. Advanced formation systems incorporate precise current/voltage control and temperature management, often meeting ANSI/UL standards for safety.

-

Testing and Grading:

The final stage involves comprehensive performance testing, including capacity, internal resistance, self-discharge rate, and safety tests. Cells are then graded based on their performance parameters. This rigorous quality assurance ensures that only cells meeting specified performance criteria are shipped. Equipment for this stage includes high-precision testers and automated sorting systems, often compliant with ISO 9001 quality management standards.

Throughout this process, product materials range from highly pure active chemicals to precision-engineered metals and polymers. Manufacturing processes like precision casting, CNC machining, and specialized forging are employed in creating the equipment itself, ensuring optimal performance and service life, typically exceeding 10 years with proper maintenance. This battery production equipment serves target industries such as electric vehicle manufacturing, consumer electronics, and grid-scale energy storage, demonstrating significant advantages in energy saving through optimized processes and corrosion resistance via advanced material coatings.

Figure 2: Precision coating machine, a vital component of lithium battery manufacturing machine.

Technical Specifications of a Modern Battery Production Line

Modern battery manufacturing equipment is characterized by high precision, robust construction, and advanced automation. Below are typical specifications for a state-of-the-art lithium ion battery manufacturing equipment line:

| Parameter | Typical Specification | Benefit to Manufacturer |

|---|---|---|

| Production Throughput | 15-30 PPM (Pouch/Prismatic) | High volume output, meeting market demand. |

| Coating Precision | ±2 µm (Thickness), ±0.5 mm (Width) | Ensures uniform electrode quality, critical for battery performance and lifespan. |

| Calendering Pressure Uniformity | <1% deviation across width | Optimized energy density and internal resistance. |

| Electrolyte Filling Accuracy | ±0.1 ml | Prevents underfilling (performance loss) or overfilling (safety risks). |

| Formation & Grading Channels | Up to 5000 independent channels | Parallel processing, high efficiency in critical conditioning phase. |

| Automation Level | Fully Automated (Robotic Handling, AGVs) | Reduced labor costs, minimized human error, increased safety. |

| Control System | Integrated PLC with SCADA/MES compatibility | Real-time monitoring, data logging, seamless integration with plant-wide systems. |

| Energy Consumption | Optimized for lowest kWh/cell | Lower operational costs, reduced environmental footprint. |

Figure 3: Advanced quality control and testing module in a battery manufacturing machine setup.

Diverse Application Scenarios

The versatility of battery production equipment extends across numerous high-growth sectors:

- Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs): Mass production of high-performance, long-range batteries for automotive applications. This segment demands the highest standards of safety and energy density.

- Consumer Electronics: Manufacturing compact, high-energy-density batteries for smartphones, laptops, wearable devices, and other portable electronics. Precision and miniaturization are key here.

- Grid-Scale Energy Storage Systems (ESS): Production of large-format batteries designed for stationary applications, supporting renewable energy integration and grid stability. Emphasis is on longevity, safety, and cost-effectiveness.

- Industrial and Specialized Applications: Powering electric forklifts, automated guided vehicles (AGVs), medical devices, and aerospace components. Customization and robust design are often paramount.

In these scenarios, the advantages of advanced lithium battery manufacturing machine are evident: significant energy saving through optimized process control, exceptional corrosion resistance due to the use of high-grade materials (e.g., stainless steel, specialized polymers) in critical components, and enhanced overall operational efficiency leading to lower per-unit production costs.

Key Technical Advantages

Investing in state-of-the-art battery manufacturing machine offers distinct competitive advantages:

- Superior Precision and Consistency: Achieving micron-level accuracy in electrode coating and stacking, ensuring uniform cell performance and extending battery lifespan. This minimizes variations that can lead to premature degradation or safety issues.

- High Throughput and Scalability: Designed for mass production, these lines can scale from pilot to giga-factory levels, meeting rapidly expanding global demand while maintaining efficiency.

- Enhanced Safety Features: Integrating advanced safety protocols, emergency shutdowns, and controlled environment systems to protect personnel and prevent hazardous incidents, especially during electrolyte handling and cell formation.

- Energy Efficiency: Optimized processes and intelligent energy management systems significantly reduce power consumption per battery cell, lowering operational costs and carbon footprint.

- Data Integration and Smart Manufacturing: Seamless integration with Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) systems enables real-time monitoring, data analytics, and predictive maintenance, aligning with Industry 4.0 principles.

Figure 4: Automated stacking and welding for precise cell assembly, a hallmark of modern battery production equipment.

Vendor Comparison and Customization Options

Choosing the right provider for battery production equipment is a strategic decision. While many offer standard lines, differentiating factors often lie in customization, after-sales support, and proven track record.

| Feature/Vendor | Leading Global Competitor A | Specialized Niche Provider B | Our Solution (e.g., XT Shuoding) |

|---|---|---|---|

| Automation Level | High, Standardized Modules | Medium to High, Specialized | High, Modular & Adaptable |

| Customization Flexibility | Limited to Standard Options | Moderate for Specific Niche | Extensive for Cell Formats & Chemistry |

| Technical Support & Expertise | Global, but potentially localized response times | Deep in specific areas, limited global reach | Dedicated project teams, rapid global response, deep process knowledge |

| Integration with MES/SCADA | Standard API, requires client configuration | Basic functionality | Full integration, customizable dashboards & data analytics |

| Cost-Effectiveness (Total Ownership) | High Initial, Moderate OPEX | Moderate Initial, Potentially Higher OPEX for parts | Competitive Initial, Optimized OPEX with strong ROI |

Customized Solutions: Recognizing that no two battery manufacturing needs are identical, providers of advanced lithium ion battery manufacturing equipment excel in offering bespoke solutions. This includes:

- Adaptation for Specific Chemistries: Tailoring equipment for different anode/cathode materials (e.g., LFP, NMC, NCA, solid-state) and electrolyte compositions.

- Cell Format Versatility: Engineering lines capable of producing cylindrical, prismatic, or pouch cells, or even hybrid setups.

- Capacity Scaling: Designing modular systems that can be easily expanded or reconfigured to meet evolving production volumes.

- Facility Integration: Providing full engineering and installation services to seamlessly integrate new equipment into existing factory layouts and infrastructure.

Figure 5: Customized battery production equipment for a specialized cell format.

Real-World Application Case Studies

Our expertise in battery production equipment has been demonstrated through successful partnerships with leading manufacturers worldwide.

-

Case Study 1: Scaling Production for a Major EV Manufacturer

A prominent electric vehicle producer needed to rapidly expand their battery module assembly capacity to meet surging market demand. We engineered and delivered a fully automated battery manufacturing machine line that integrated seamlessly with their existing factory infrastructure. The solution included high-speed cell sorting, module welding, and advanced quality inspection systems. Result: The client achieved a 40% increase in production throughput within six months, significantly reducing time-to-market for their new EV models and maintaining a defect rate below 0.05%.

-

Case Study 2: Precision Manufacturing for Medical Devices

A medical device company required ultra-high precision battery production for miniature, implantable power sources. Our customized lithium battery manufacturing machine provided exceptionally tight tolerances for electrode coating and electrolyte filling, critical for the safety and longevity of their sensitive products. We implemented a specialized cleanroom-compatible line with advanced environmental controls. Result: The client achieved unprecedented consistency in cell performance, extended product warranty periods, and successfully passed stringent medical device certifications, including FDA compliance for manufacturing processes.

-

Case Study 3: Optimizing Energy Storage for Grid Applications

A leading utility provider sought to improve the cost-effectiveness and durability of their grid-scale energy storage battery production. We supplied battery formation equipment with advanced cycling profiles and integrated diagnostics, specifically designed for large-format prismatic cells. The system allowed for dynamic formation protocols that optimized the SEI layer for longer cycle life and reduced initial degradation. Result: The client reported a 15% improvement in battery cycle life compared to their previous production methods, leading to substantial long-term cost savings and enhanced grid reliability.

Frequently Asked Questions (FAQ)

A: Lead times vary depending on the complexity and customization required. For a standard, pre-configured line, it's typically 12-16 weeks. Highly customized solutions or giga-factory scale projects may require 6-12 months for design, manufacturing, and installation.

A: We adhere to stringent quality control protocols, including ISO 9001 certified manufacturing, extensive factory acceptance testing (FAT), and site acceptance testing (SAT). All critical components are sourced from reputable global suppliers. Our equipment also undergoes rigorous simulation and real-world testing before deployment.

A: Yes, our battery production equipment is designed with flexibility in mind. Many modules can be adjusted or upgraded to accommodate various battery chemistries and cell formats, including solid-state battery manufacturing requirements. We offer consultation to tailor solutions to specific material needs.

A: We provide comprehensive operator and maintenance training both at our facility and on-site. Our after-sales support includes a dedicated technical team, remote diagnostics, regular maintenance schedules, and a readily available spare parts inventory to ensure continuous operation.

Figure 6: A control panel for monitoring and managing battery production equipment processes.

Lead Time, Warranty, and Customer Support

-

Lead Time & Fulfillment:

Our project management approach ensures transparent communication from order placement to final commissioning. Standard battery production equipment lines typically have a lead time of 12-16 weeks for manufacturing and initial testing. Complex, fully customized, or large-scale integrated solutions may require 6-12 months, including detailed engineering, procurement, fabrication, and extensive testing phases. We provide comprehensive logistics support, including shipping, customs clearance assistance, and on-site installation by our certified engineers.

-

Warranty Commitments:

We stand by the quality and performance of our battery manufacturing equipment with a standard 12 to 24-month warranty on parts and labor, effective from the date of final acceptance. Extended warranty options are available for enhanced peace of mind. Our warranty covers manufacturing defects and ensures the equipment operates according to specified technical parameters, providing assurance for your long-term investment.

-

Customer Support & After-Sales Service:

Our commitment extends beyond delivery. We offer robust after-sales support designed to maximize your operational uptime and efficiency. This includes 24/7 technical assistance, remote diagnostic services, readily available spare parts, and scheduled preventative maintenance programs. Our global network of service engineers is prepared for on-site support, training your personnel, and ensuring optimal performance throughout the equipment's lifecycle. Your success is our priority.

References

- BloombergNEF. (2023). Electric Vehicle Outlook 2023. [Market Research Report]

- International Energy Agency (IEA). (2022). Global EV Outlook 2022. [Official Publication]

- Grand View Research. (2023). Lithium-Ion Battery Market Size, Share & Trends Analysis Report. [Industry Report]

- ISO (International Organization for Standardization). (2023). ISO 9001 Quality Management Systems – Requirements. [Standard Documentation]

- Advanced Battery Concepts. (2023). Innovations in Battery Manufacturing Processes. [Technical Article]

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025