Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System

Advanced New Energy Lithium Battery PACK Automated Assembly Production Line System

1: Introduction:

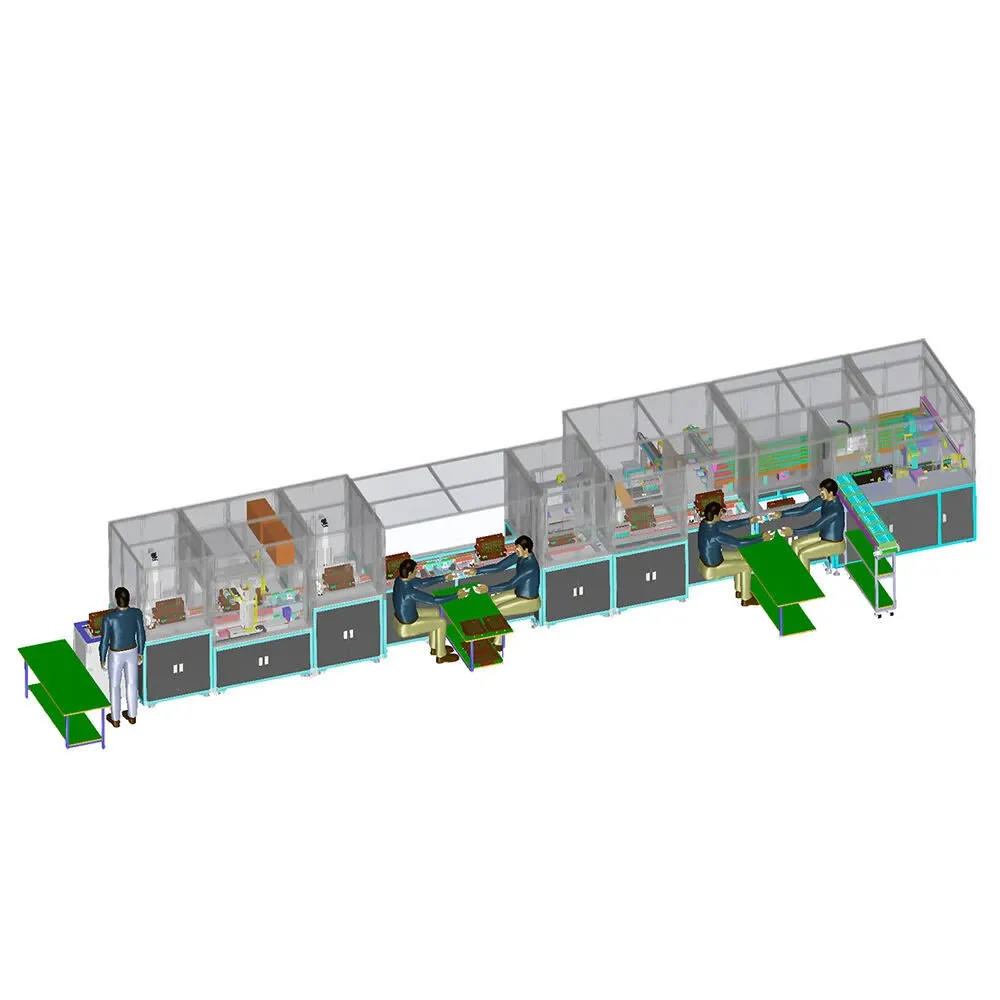

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following equipment:

2: Precision battery feeding and paper pad placement station:

- AI-driven automatic sorting based on comprehensive battery loading test data.

- High-speed robotic battery assembly with multi-axis precision control.

- Advanced battery pack nickel welding station with real-time quality monitoring.

- Precision BMS PCB soldering station with temperature and pressure control.

- Intelligent battery pack finished product handling and packaging system.

3: Application:

• New energy vehicles (EVs, HEVs, PHEVs)

• High-performance portable electronic devices

• Grid-scale and residential energy storage systems

• Aerospace and marine applications

• Industrial power tools and equipment

4: Technical Features:

- Industry 4.0 compliant fully automated operation, dramatically improving production efficiency.

- Advanced integrated CCD vision identification system ensuring micron-level accuracy.

- AI-powered automatic feeding and sorting mechanism, guaranteeing optimal cell consistency.

- Real-time automatic barcode scanning and binding, enabling comprehensive product lifecycle traceability.

- Seamless integration with MES and ERP systems, facilitating complete recording and analysis of product manufacturing data.

- State-of-the-art robotics replacing traditional manual operations, ensuring unparalleled product quality stability.

- Modular design allowing independent operation of each equipment, with user-friendly interfaces for easy operation and maintenance.

- Remote monitoring and predictive maintenance capabilities.

- Energy-efficient design with power management system.

- Flexible production capabilities, accommodating various battery sizes and configurations.

5: Additional Features:

• Customizable production modules to meet specific client needs

• Virtual reality (VR) based operator training system

• Digital twin technology for real-time process optimization

• Green manufacturing practices with minimal environmental impact

• 24/7 global technical support and remote diagnostics

6: Technical Parameters:

- Total production line length: 16 meters.

- Production capacity: Up to X battery packs per hour (customizable).

- Precision level: ±0.1mm positioning accuracy.

- Processing efficiency: 99.5% uptime.

- Product quality consistency: >99.9%.

- Operational safety: Advanced multi-level safety protocols.

- Data acquisition: Real-time, full process monitoring with 1000+ data points.

- Information integration level: High, achieving seamless information interaction between production planning, execution, and control layers.

- Energy consumption: 30% lower than industry standard.

- Adaptability: Capable of handling multiple battery types (18650, 21700, prismatic, pouch).

Nouvelles