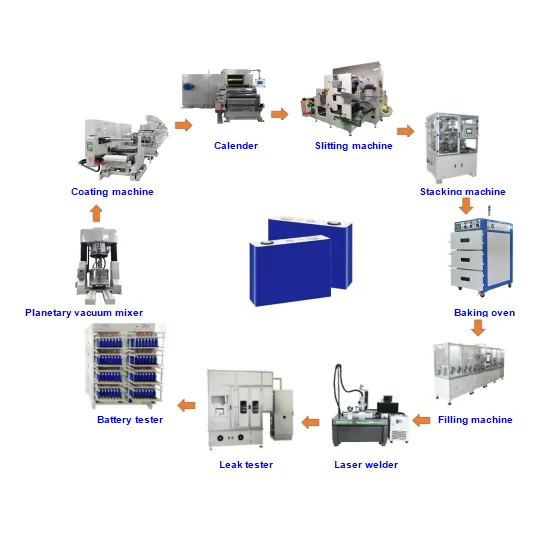

pouch cell manufacturing

The evolution of energy storage solutions has cast a spotlight on the prismatic cell manufacturing machine, a pivotal apparatus in the production of next-generation batteries. Known for their high energy density and enhanced safety profiles, prismatic cells are setting new standards in the industry. The manufacturing machinery behind these cells plays a crucial role in maintaining these standards by ensuring precision, efficiency, and reliability.

In the realm of prismatic cell manufacturing, experience is indispensable. Manufacturers with a rich history in machine development have refined their processes to meet the nuanced demands of battery technology. These machines are designed with the operators in mind, incorporating user-friendly interfaces that minimize the learning curve while maximizing operational throughput. This is not just about producing cells; it's about producing quality cells that align with stringent industry standards.

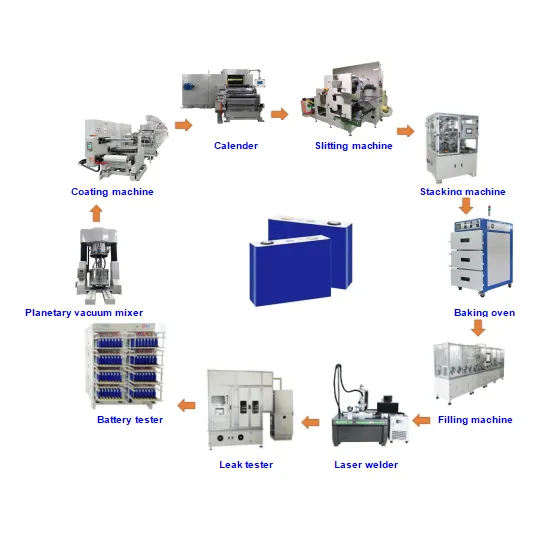

The expertise embedded within prismatic cell manufacturing machines is evident through their highly specialized components. Precision engineering ensures that electrode cutting, stacking, and packaging are performed with exactitude. Advanced control systems, often integrated with AI capabilities, monitor each phase of production. This level of detail not only enhances the performance and lifespan of the cells but also reduces material waste, which is a significant concern in large-scale manufacturing processes.

Authoritativeness in the manufacturing of prismatic cell machines stems from the collaboration between leading engineers and scientists. These experts bring decades of research and field experience together, innovating designs that push the boundaries of existing technologies. Their contributions ensure that the equipment stays ahead of industry demands, offering solutions that cater to a wide range of applications from automotive to consumer electronics.

prismatic cell manufacturing machine

Trustworthiness is built into the prismatic cell manufacturing machine through rigorous testing and compliance with international standards. Each machine undergoes extensive trials and quality checks before becoming operational in production lines. This commitment to quality is not only about safeguarding the manufacturer's reputation but also about ensuring the safety and reliability of the end products. Manufacturers of these machines understand the critical role they play in the supply chain of battery production and strive to uphold the trust placed in them by their partners and clients.

Additionally, the innovation embedded within these machines reflects a commitment to sustainability. As the world pivots towards greener technologies, prismatic cell manufacturing machines are designed to support eco-friendly production practices that significantly lower the carbon footprint. This forward-thinking approach also encompasses developments in materials and methods, which further solidifies the manufacturer's position as not just participants, but leaders in pioneering sustainable battery solutions.

Through sound experience, specialized expertise, established authoritativeness, and unwavering trustworthiness, prismatic cell manufacturing machines are integral to the production of safer, more efficient, and environmentally responsible batteries. This focus on excellence not only benefits the end-users but also propels the entire energy storage industry towards a smarter and more sustainable future.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025