Energy Efficiency in Modern Battery Formation Equipment

In the ever - evolving landscape of battery manufacturing, energy efficiency has emerged as a crucial factor for producers aiming to cut costs, reduce environmental impact, and enhance competitiveness. Battery production equipment, battery formation equipment, and lithium ion battery making machine from Xingtai Shuoding Trading Co., Ltd. are engineered with advanced technologies to optimize energy consumption, presenting an excellent opportunity for wholesalers to offer high - value solutions to their customers.

Advanced Energy - Saving Features of Battery Formation Equipment

- Intelligent Power Management Systems: Battery formation equipment from Xingtai Shuoding Trading Co., Ltd. is equipped with intelligent power management systems. These systems monitor and adjust the power supply according to the actual load of the equipment during the battery formation process. For instance, when the formation process enters a low - energy - demand phase, the power consumption is automatically reduced, minimizing unnecessary energy waste. This intelligent control ensures that energy is used only when and where it's needed, optimizing overall energy efficiency.

- Precision Temperature Control: Maintaining the right temperature is vital in battery formation, and inefficient temperature control can lead to excessive energy use. The battery formation equipmentfeatures precision temperature control mechanisms. By accurately regulating the temperature within the formation chambers, it reduces the energy required for heating or cooling. This not only saves energy but also improves the quality and consistency of battery formation, as stable temperatures are crucial for proper chemical reactions during the process.

- Regenerative Energy Technologies: Incorporating regenerative energy technologies, the battery formation equipmentrecovers and reuses energy that would otherwise be wasted. For example, during certain stages of the battery formation process, kinetic or thermal energy generated can be captured and converted back into electrical energy, which can then be used to power other parts of the equipment or stored for later use. This innovative approach significantly enhances the overall energy efficiency of the battery formation process.

Optimized Performance of Battery Production Equipment

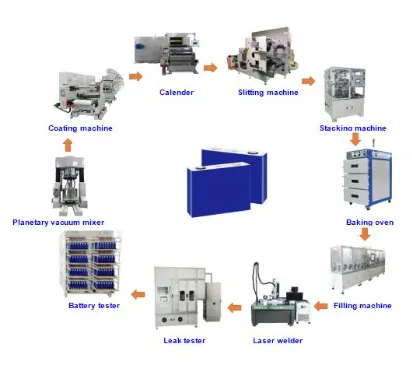

- Streamlined Production Processes: Battery production equipmentis designed to streamline the entire battery manufacturing process, reducing the time and energy required for production. Integrated systems ensure smooth material handling, component assembly, and quality control, eliminating redundant steps that consume unnecessary energy. By optimizing the workflow, the equipment enables continuous and efficient production, maximizing output while minimizing energy input per unit of production.

- High - Speed and High - Precision Operations:The high - speed and high - precision capabilities of battery production equipment contribute to energy efficiency. Faster production cycles mean that more batteries can be produced in less time, reducing the overall energy consumption per battery. Additionally, high - precision operations ensure that the production process is error - free, minimizing the need for rework, which would otherwise consume additional energy and resources.

- Modular and Scalable Design: With a modular and scalable design, battery production equipmentallows manufacturers to adjust production capacity according to demand. When production requirements are low, only the necessary modules can be operated, reducing energy consumption. As demand increases, additional modules can be easily added without significant energy inefficiencies. This flexibility ensures that energy is used efficiently at all production levels.

Specialized Efficiency of Lithium Ion Battery Making Machine

- Tailored Chemical Processes:Lithium ion battery making machine is specifically engineered to optimize the chemical processes unique to lithium - ion battery production. By precisely controlling chemical reactions, such as electrolyte filling and electrode activation, the equipment reduces energy losses associated with incomplete or inefficient reactions. This tailored approach not only improves the performance and lifespan of lithium - ion batteries but also enhances the energy efficiency of the manufacturing process.

- Advanced Material Handling: Efficient material handling is a key aspect of energy - efficient lithium - ion battery production. The lithium ion battery making machinefeatures advanced material handling systems that minimize material waste and ensure accurate dosing. By reducing material waste, less energy is consumed in the production of additional materials to compensate for losses. Moreover, accurate material handling contributes to the consistency and quality of the batteries, reducing the likelihood of energy - consuming rework.

- Energy - Conscious Component Selection:In the design of lithium ion battery making machine, energy - conscious component selection is prioritized. Components with high energy - conversion efficiencies and low standby power consumption are used. This choice of components, from motors to control units, collectively reduces the overall energy consumption of the equipment, making it a more sustainable and cost - effective option for lithium - ion battery production.

Battery Formation Equipment FAQS

How does the intelligent power management system in battery formation equipment save energy?

The intelligent power management system in battery formation equipment continuously monitors the equipment's load during the battery formation process. When the process enters phases with lower energy demands, such as the final stages of charging or when waiting for chemical reactions to stabilize, the system automatically reduces the power supply. This prevents energy from being wasted on unnecessary high - power operations, ensuring that energy is used only as required, thus significantly saving energy over the course of battery formation.

What role does the modular design of battery production equipment play in energy efficiency?

The modular design of battery production equipment allows manufacturers to adapt production capacity to demand. During periods of low production needs, only the essential modules of the equipment can be operated, consuming less energy. As demand rises, additional modules can be added seamlessly without causing significant energy inefficiencies. This adaptability ensures that energy is not wasted on operating unnecessary components, optimizing energy use across different production scales.

How does the lithium ion battery making machine optimize chemical processes for energy efficiency?

The lithium ion battery making machine is designed to precisely control the chemical processes specific to lithium - ion battery production. It accurately regulates parameters such as electrolyte filling levels, reaction temperatures, and activation times. By ensuring that these chemical reactions occur optimally, it reduces energy losses that would otherwise result from incomplete or inefficient reactions. This optimization not only improves battery performance but also enhances the overall energy efficiency of the manufacturing process.

Can the energy - saving features of battery formation equipment affect battery quality?

No, the energy - saving features of battery formation equipment are designed to enhance both energy efficiency and battery quality. For example, the precision temperature control mechanisms maintain stable temperatures during formation, which is crucial for proper chemical reactions and consistent battery quality. The intelligent power management systems ensure that the equipment operates within the optimal parameters for battery formation, while the regenerative energy technologies do not interfere with the formation process. Instead, they contribute to a more sustainable and high - quality manufacturing environment.

How does Xingtai Shuoding Trading Co., Ltd. ensure the energy efficiency of its lithium ion battery making machine?

Xingtai Shuoding Trading Co., Ltd. ensures the energy efficiency of its lithium ion battery making machine through multiple strategies. It uses energy - conscious component selection, choosing parts with high energy - conversion efficiencies and low standby power consumption. The company also focuses on optimizing material handling to reduce waste and improve process efficiency. Additionally, the machine is designed to precisely control chemical processes, minimizing energy losses associated with inefficient reactions. Through these comprehensive approaches, the company delivers lithium ion battery making machine that are both energy - efficient and high - performing.

Raba

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeLabaraiNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseLabaraiNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyLabaraiNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseLabaraiNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileLabaraiNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedLabaraiNov.10,2025