What Is the Sanctity of Car Door Seal Strips?

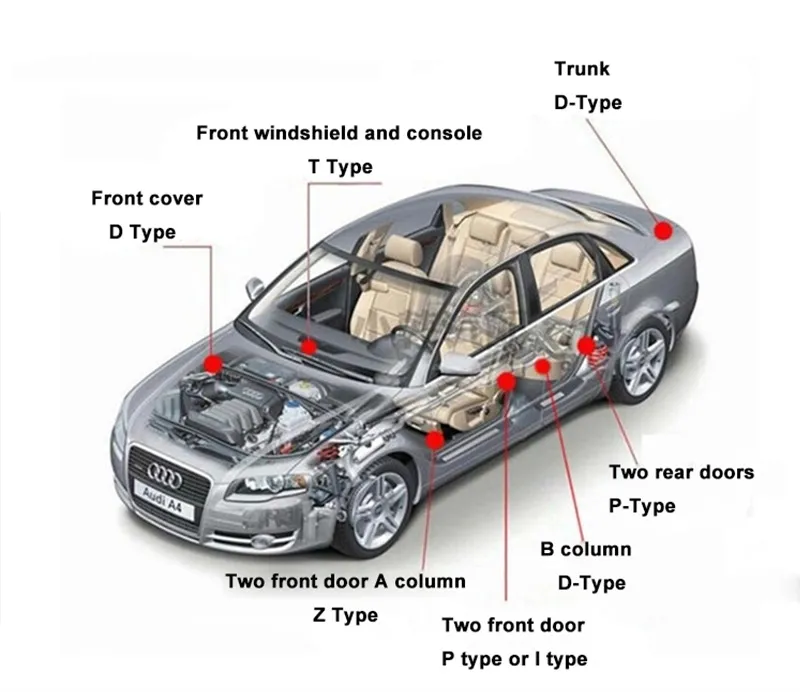

The application range of car door seal strips is quite extensive, not only visible to the naked eye at the door leaf and frame, but also in places such as side windows, front and rear windshields, engine hood, and trunk lid. It can be said that as long as there are gaps between body components and areas that need to be sealed, there is a high probability that car door seal strips can be found to hold their positions.

The "Past and Present" Of Car Door Seal Strips

The development of car door seal strips is a "micro evolution history" of the automotive industry. In the early years, shortly after the birth of automobiles, the kāʻei hoʻopaʻa kaʻa materials were simple and rough, mostly natural rubber, asbestos, etc. The production process relied mainly on simple extrusion molding, and the functions were also very single, which could only barely achieve basic sealing. The waterproof and sound insulation effects were unsatisfactory, and the interior environment of the car was far less comfortable than it is now.

With the rapid development of the automotive industry, kāʻei hoʻopaʻa kaʻa technology has also undergone rapid innovation. In terms of materials, Ethylene Propylene Diene Monomer (EPDM) has become mainstream, with strong weather resistance. It can stably protect the car doors regardless of extreme cold, heat, wind, rain, etc; New materials such as thermoplastic elastomers (TPE) have also emerged, combining environmental friendliness and high performance. In terms of craftsmanship, from simple extrusion at the beginning, complex and precise injection molding and compression molding have been developed, which can produce various exquisite structures such as multi chamber and composite kāʻei hoʻopaʻa kaʻas, greatly improving sealing and sound insulation capabilities.

Recent Developments in Car Door Seal Strips

In recent years, new energy vehicles have emerged as a rising force, and car door seal strips have also kept up with the times. In order to meet the ultimate pursuit of range for new energy vehicles, the kāʻei hoʻopaʻa kaʻa has made great efforts in lightweighting, using thinner yet more durable materials to reduce body weight and energy consumption; At the same time, in response to the characteristics of multiple electronic devices and high requirements for quietness in new energy vehicles, the sound insulation structure is further optimized by adding sound-absorbing materials to more thoroughly isolate noise, creating an ultra quiet atmosphere inside the car and helping the driving experience reach new heights.

Although the car door seal strip is small, it truly affects our daily driving experience. It shoulders the heavy responsibility of waterproofing, sound insulation, dust prevention, temperature insulation, shock absorption, etc., and comprehensively safeguards the comfort and safety inside the car. Understanding its development process can make us feel the progress of the automotive industry.

Kaʻana like

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNūhouNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNūhouNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNūhouNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNūhouNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNūhouNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNūhouNov.10,2025