Jan . 09 , 2025 13:42

Back to list

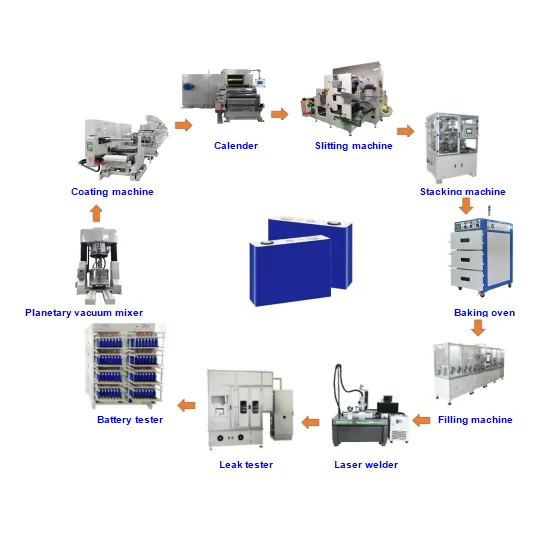

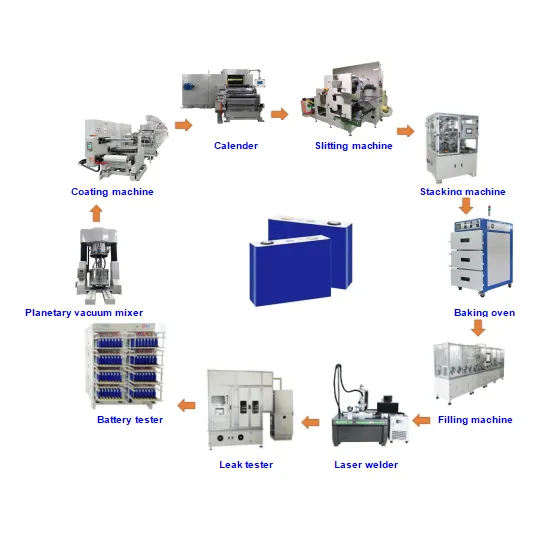

pouch cell manufacturing

In the bustling realm of battery technology, the prismatic cell manufacturing machine stands as a cornerstone of modern energy solutions. Known for its sleek design and efficient energy output, the prismatic cell has revolutionized the way energy is stored and utilized, making it an indispensable component in electric vehicles and consumer electronics.

Trustworthiness in prismatic cell production is primarily built through rigorous testing and validation processes. Before reaching the market, each cell must undergo extensive quality testing to evaluate its electrical performance, thermal stability, and lifespan. The best machines integrate these testing protocols into the production line, providing real-time feedback and ensuring that only cells that meet the highest standards progress down the line. The complexity of producing reliable prismatic cells also demands substantial expertise in material science. The choice of materials for electrodes, separators, and electrolytes dramatically impacts the performance and safety of the final product. Manufacturers invest heavily in research and partnerships with leading material scientists to innovate and enhance these components, pushing the boundaries of what prismatic cells can achieve. Authoritativeness in this field comes from the continuous pursuit of innovation and improvement. Leading manufacturers are heavily involved in industry collaborations and standard-setting organizations to stay ahead in technology and production methodologies. With a focus on sustainability, there has been a strong shift towards developing eco-friendly production processes and recyclable materials, ensuring that the lifecycle of prismatic cells is environmentally responsible. Transitioning to a practical application, potential investors and decision-makers in the energy sector should consider the long-term benefits and capabilities of prismatic cell manufacturing machines. While the initial investment might seem substantial, the long-term gains in efficiency, reliability, and market adaptability significantly outweigh the costs. Investing in quality machinery not only enhances production but also solidifies a company’s position as an innovator and leader in the competitive energy market. In conclusion, the landscape of prismatic cell manufacturing is as dynamic as it is vital. The machines at the heart of this industry are not merely tools of production; they symbolize cutting-edge innovation and the relentless pursuit of energy efficiency. As the world gravitates towards sustainable energy solutions, the role of these manufacturing machines will undoubtedly continue to grow, driving both technological progress and environmental stewardship.

Trustworthiness in prismatic cell production is primarily built through rigorous testing and validation processes. Before reaching the market, each cell must undergo extensive quality testing to evaluate its electrical performance, thermal stability, and lifespan. The best machines integrate these testing protocols into the production line, providing real-time feedback and ensuring that only cells that meet the highest standards progress down the line. The complexity of producing reliable prismatic cells also demands substantial expertise in material science. The choice of materials for electrodes, separators, and electrolytes dramatically impacts the performance and safety of the final product. Manufacturers invest heavily in research and partnerships with leading material scientists to innovate and enhance these components, pushing the boundaries of what prismatic cells can achieve. Authoritativeness in this field comes from the continuous pursuit of innovation and improvement. Leading manufacturers are heavily involved in industry collaborations and standard-setting organizations to stay ahead in technology and production methodologies. With a focus on sustainability, there has been a strong shift towards developing eco-friendly production processes and recyclable materials, ensuring that the lifecycle of prismatic cells is environmentally responsible. Transitioning to a practical application, potential investors and decision-makers in the energy sector should consider the long-term benefits and capabilities of prismatic cell manufacturing machines. While the initial investment might seem substantial, the long-term gains in efficiency, reliability, and market adaptability significantly outweigh the costs. Investing in quality machinery not only enhances production but also solidifies a company’s position as an innovator and leader in the competitive energy market. In conclusion, the landscape of prismatic cell manufacturing is as dynamic as it is vital. The machines at the heart of this industry are not merely tools of production; they symbolize cutting-edge innovation and the relentless pursuit of energy efficiency. As the world gravitates towards sustainable energy solutions, the role of these manufacturing machines will undoubtedly continue to grow, driving both technological progress and environmental stewardship.

Share

Latest news

-

The Ultimate Guide to Square Files for Precision WorkNewsJun.26,2025

-

The Power of Flat FilesNewsJun.26,2025

-

Revolutionize Your Craft with High-Performance Rotary FilesNewsJun.26,2025

-

Precision and Durability with Diamond-Coated Needle FilesNewsJun.26,2025

-

Essential Tools for Precision Work: Round Metal Files and MoreNewsJun.26,2025

-

Essential Tools for Precision Sharpening: Triangular FilesNewsJun.26,2025