Jan . 09 , 2025 14:10

Back to list

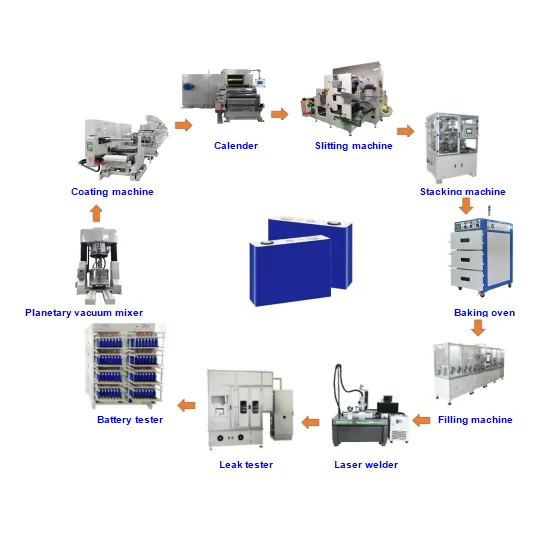

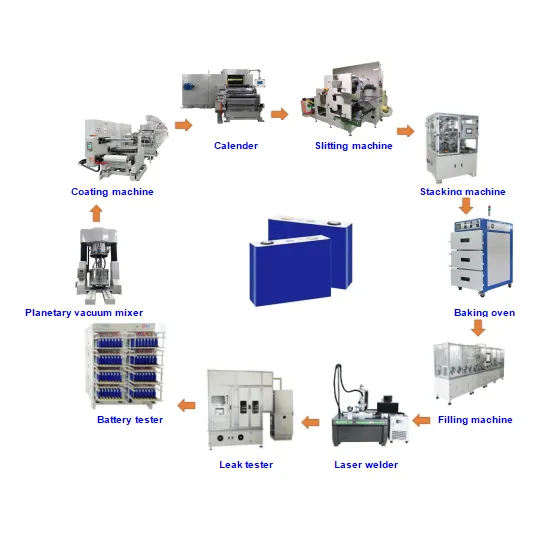

prismatic cell manufacturing machine

In recent years, the prismatic cell manufacturing industry has experienced significant advancements, leading to increased demand for specialized manufacturing machines. These machines are essential in producing high-quality prismatic battery cells, a preferred choice for electric vehicles and renewable energy storage systems due to their superior energy density and safety features.

The authority of a prismatic cell manufacturing machine provider can often be gauged by their track record in innovation and customer support. Established providers invest significantly in R&D to continually refine machine performance and explore new manufacturing technologies. They also offer comprehensive aftersales services, including training, maintenance, and support, ensuring their clients can fully harness the potential of their investment. Trust in prismatic cell manufacturing machines is also built through demonstrable experiences shared by existing users. Case studies and testimonials often highlight how specific machines have enabled manufacturers to scale operations, improve the quality of battery cells, and achieve higher efficiency levels. These real-world experiences provide prospective buyers with confidence in the capabilities and reliability of the machines. Looking ahead, the future of prismatic cell manufacturing machines seems promising, with ongoing research focused on integrating artificial intelligence and machine learning. These technologies are expected to revolutionize predictive maintenance, allowing manufacturers to anticipate and rectify potential issues before they disrupt production. Additionally, sustainable practices are gaining traction, with manufacturers seeking machines that minimize waste and optimize resource usage, aligning with global environmental goals. To conclude, prismatic cell manufacturing machines are pivotal to the advancement of battery technology. Their development and optimization are vital in meeting the global shift toward sustainable energy solutions. By prioritizing experience, expertise, authoritativeness, and trustworthiness, manufacturers of these machines not only spearhead innovation within the industry but also empower battery producers to meet tomorrow’s energy challenges effectively.

The authority of a prismatic cell manufacturing machine provider can often be gauged by their track record in innovation and customer support. Established providers invest significantly in R&D to continually refine machine performance and explore new manufacturing technologies. They also offer comprehensive aftersales services, including training, maintenance, and support, ensuring their clients can fully harness the potential of their investment. Trust in prismatic cell manufacturing machines is also built through demonstrable experiences shared by existing users. Case studies and testimonials often highlight how specific machines have enabled manufacturers to scale operations, improve the quality of battery cells, and achieve higher efficiency levels. These real-world experiences provide prospective buyers with confidence in the capabilities and reliability of the machines. Looking ahead, the future of prismatic cell manufacturing machines seems promising, with ongoing research focused on integrating artificial intelligence and machine learning. These technologies are expected to revolutionize predictive maintenance, allowing manufacturers to anticipate and rectify potential issues before they disrupt production. Additionally, sustainable practices are gaining traction, with manufacturers seeking machines that minimize waste and optimize resource usage, aligning with global environmental goals. To conclude, prismatic cell manufacturing machines are pivotal to the advancement of battery technology. Their development and optimization are vital in meeting the global shift toward sustainable energy solutions. By prioritizing experience, expertise, authoritativeness, and trustworthiness, manufacturers of these machines not only spearhead innovation within the industry but also empower battery producers to meet tomorrow’s energy challenges effectively.

Share

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025