Advanced Battery Production Equipment for Efficient Manufacturing

The Foundation of Future Energy: Advanced Battery Production Equipment

In an era defined by the rapid transition towards sustainable energy, the demand for high-performance and reliable batteries is skyrocketing. This unprecedented growth necessitates cutting-edge battery production equipment that can meet stringent quality, efficiency, and scalability requirements. From electric vehicles (EVs) and grid-scale energy storage systems (ESS) to consumer electronics, the quality and cost-effectiveness of battery cells are directly influenced by the sophistication of the manufacturing machinery employed. This comprehensive overview delves into the critical aspects of battery manufacturing, exploring the intricate process flows, technical specifications, strategic advantages, and the pivotal role of advanced machinery in shaping the future of energy storage.

The journey of a battery cell, from raw material to a fully functional energy storage unit, is a complex sequence of highly precise operations. Each stage, from electrode material preparation to cell formation and testing, relies on specialized machinery designed for accuracy, throughput, and reliability. This document aims to provide B2B decision-makers and technical engineers with a deep understanding of the capabilities and considerations when investing in state-of-the-art battery manufacturing solutions.

Industry Trends Shaping Battery Manufacturing Equipment

The battery industry is in a perpetual state of innovation, driven by advancements in materials science, increasing energy density demands, and the global push for decarbonization. Several key trends are profoundly impacting the development and deployment of battery production equipment:

- Automation and Industry 4.0 Integration: The shift towards fully automated, intelligent production lines is paramount. This includes robotics, AI-driven process optimization, real-time data analytics, and predictive maintenance to maximize uptime and efficiency.

- Sustainability and Circular Economy: Equipment is increasingly designed to reduce energy consumption, minimize waste, and enable easier recycling of materials. This extends to process water treatment and solvent recovery systems.

- Advanced Battery Chemistries and Form Factors: The emergence of solid-state batteries, sodium-ion batteries, and new cell designs (e.g., large prismatic, blade batteries, 4680 cylindrical cells) necessitates flexible and adaptable lithium battery manufacturing machine designs.

- Enhanced Safety Protocols: Given the inherent risks associated with high-energy materials, advanced safety features, robust process controls, and fire suppression systems are integral to modern equipment design.

- Increased Production Scale: Gigafactories demand equipment with higher throughput, greater reliability, and seamless integration capabilities to achieve economies of scale.

According to recent market analysis, the global lithium-ion battery market size was valued at USD 57.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 19.3% from 2023 to 2030, driven predominantly by the automotive sector. This robust growth directly translates into an escalating demand for sophisticated battery manufacturing equipment capable of producing high-quality cells at unprecedented volumes.

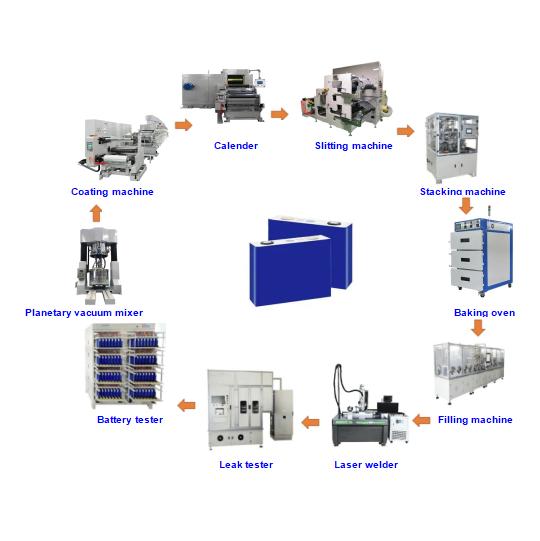

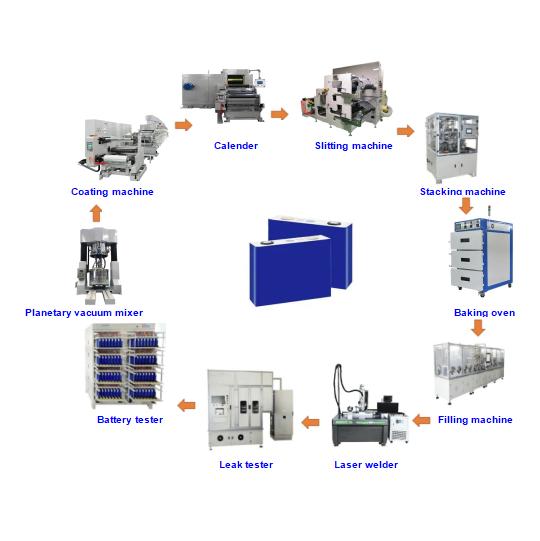

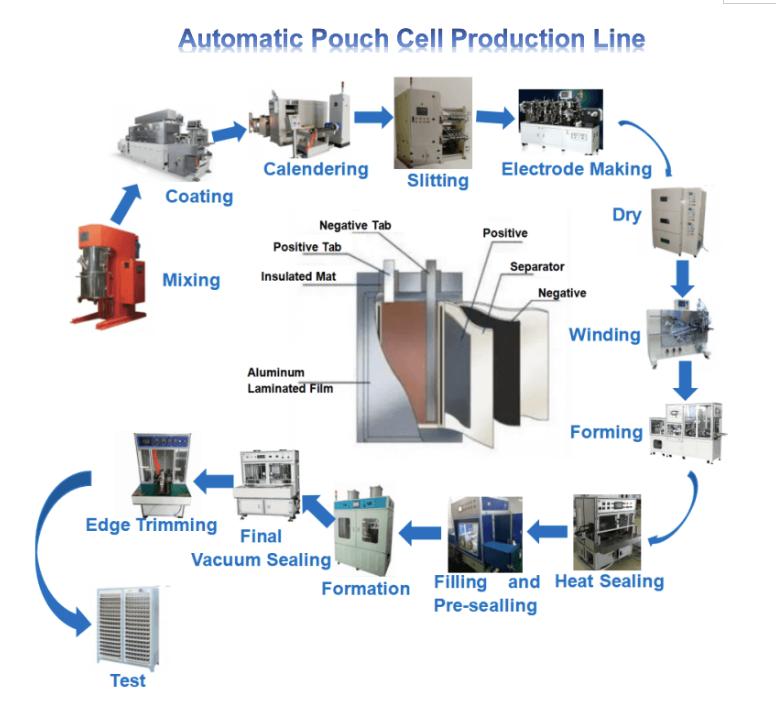

Comprehensive Process Flow of Battery Production Equipment Lines

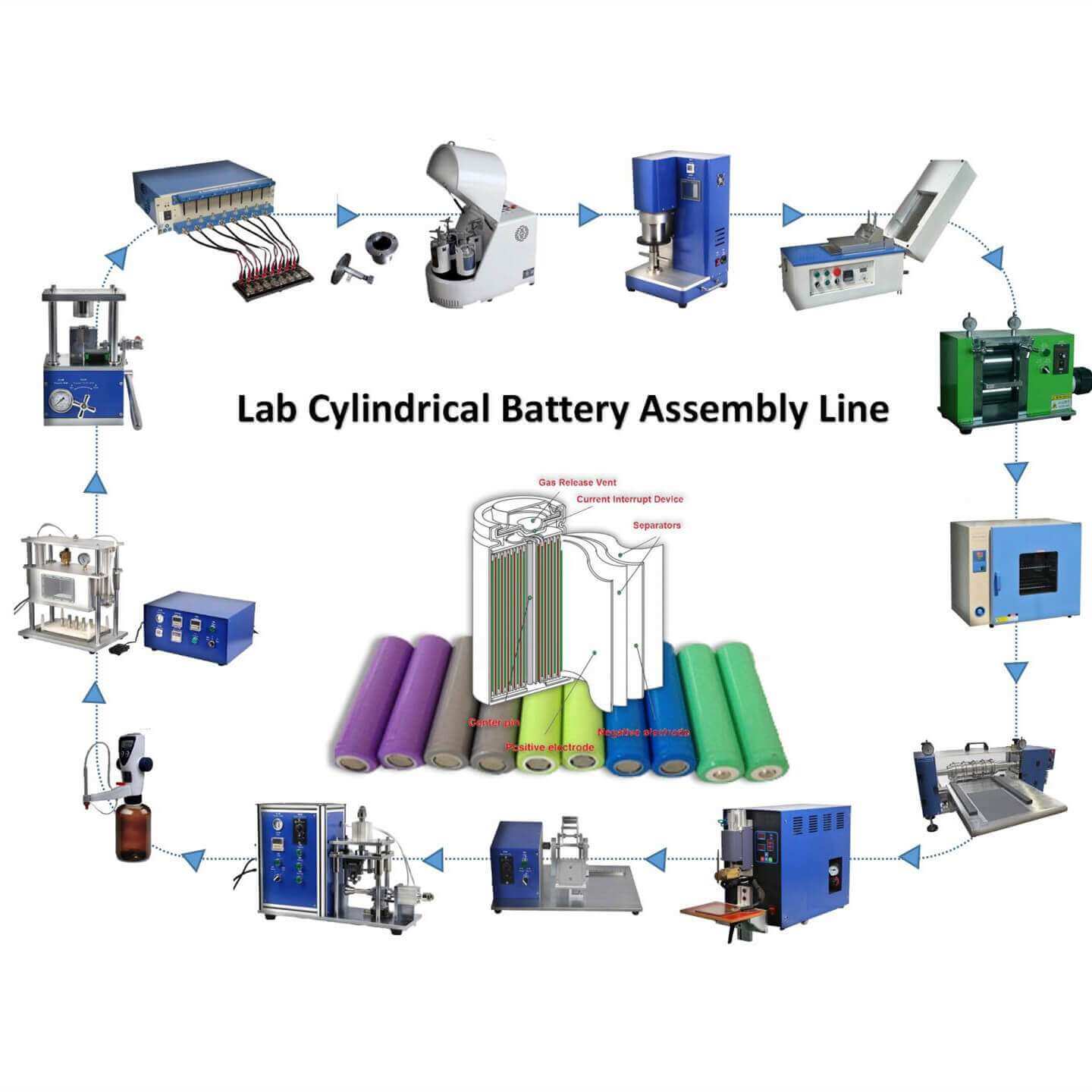

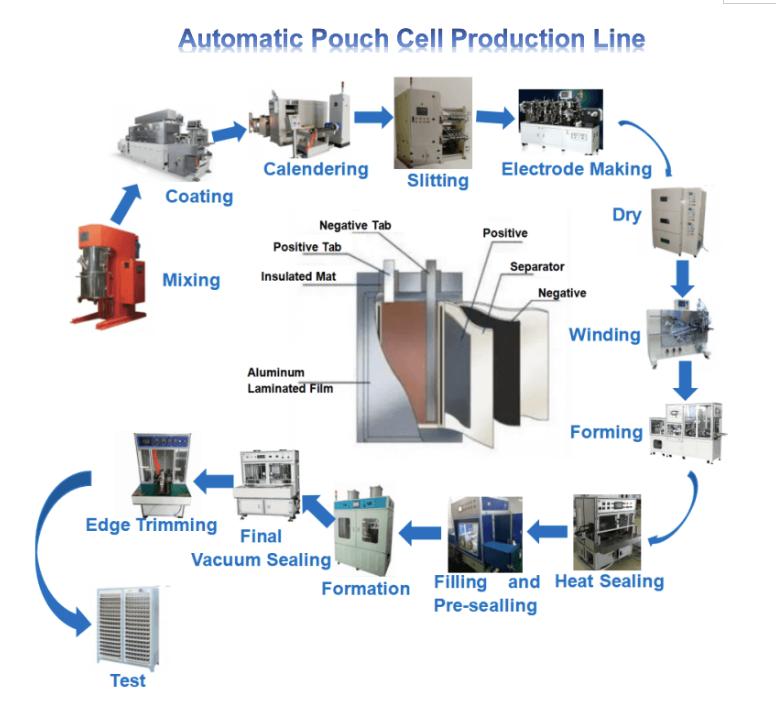

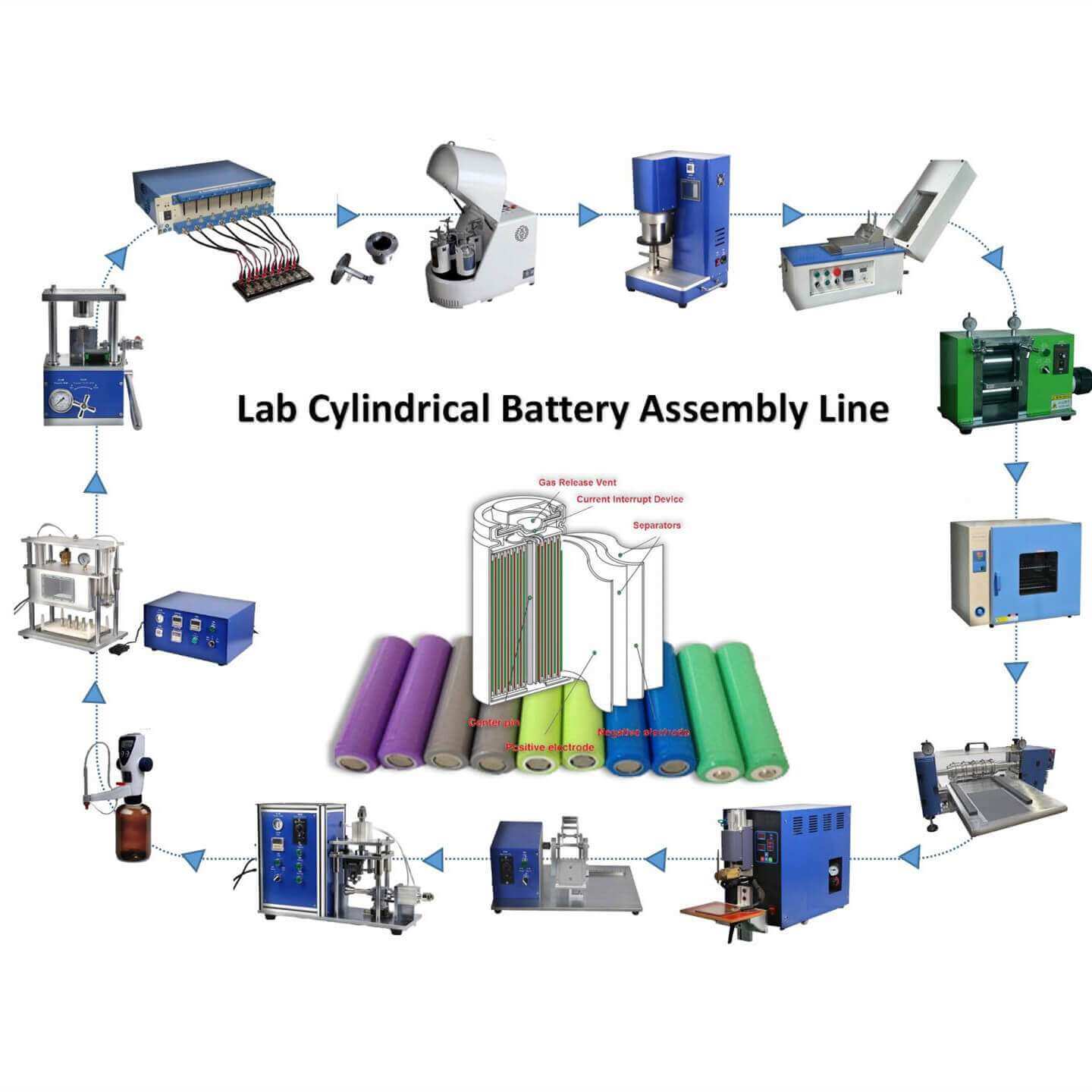

The manufacturing of lithium-ion batteries is a multi-stage process, each requiring specialized battery manufacturing machine to ensure precision and quality. The entire line can be broadly categorized into front-end, mid-end, and back-end processes.

1. Front-End: Electrode Preparation

- Slurry Mixing: Active materials (e.g., LiNMC, LFP for cathode; graphite for anode), conductive additives, and binders are precisely mixed with solvents to create a homogeneous slurry. This stage demands high-shear mixers and vacuum degassers to prevent air bubbles, critical for electrode performance.

- Coating: The slurry is precisely coated onto current collectors (aluminum foil for cathode, copper foil for anode). High-precision coaters (e.g., slot die coater) ensure uniform thickness and consistent active material loading. Key parameters like coating gap, speed, and tension are meticulously controlled.

- Drying: Coated foils pass through multi-zone ovens to evaporate solvents. Controlled temperature profiles and airflow are crucial to prevent cracking and ensure proper adhesion.

- Calendering: The dried electrodes are compressed between rollers to achieve desired thickness and density. Calendering machines must provide uniform pressure across the width to optimize energy density and reduce internal resistance.

- Slitting: Large rolls of calendered electrodes are precisely cut into narrower strips suitable for cell assembly. Slitting machines ensure clean, burr-free edges, vital for preventing internal shorts.

Manufacturing Processes for Equipment: Components of these machines often undergo precision CNC machining, forging for robust rollers, and advanced coating techniques for wear resistance. Testing standards typically adhere to ISO 9001 for quality management and ANSI standards for machine safety.

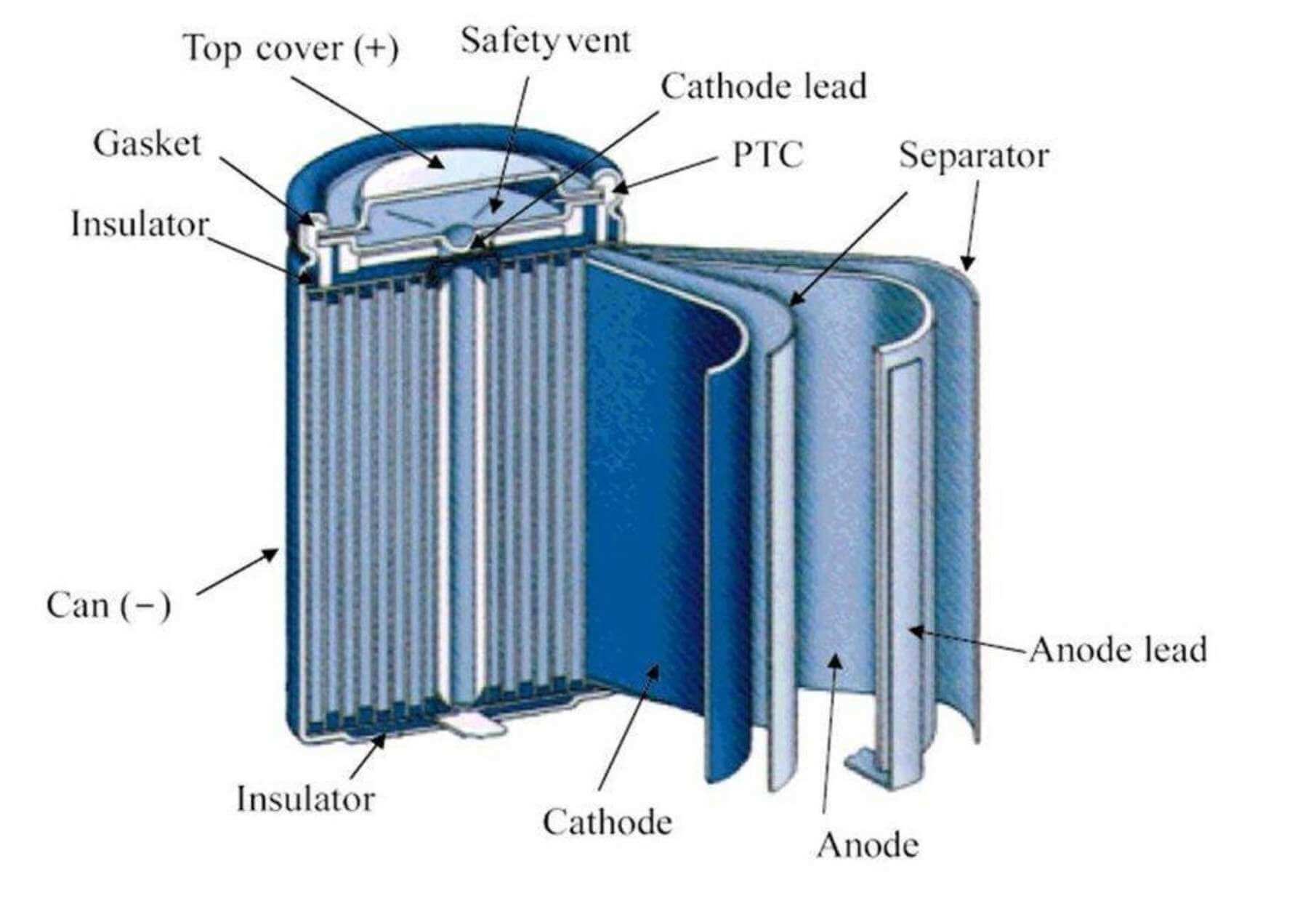

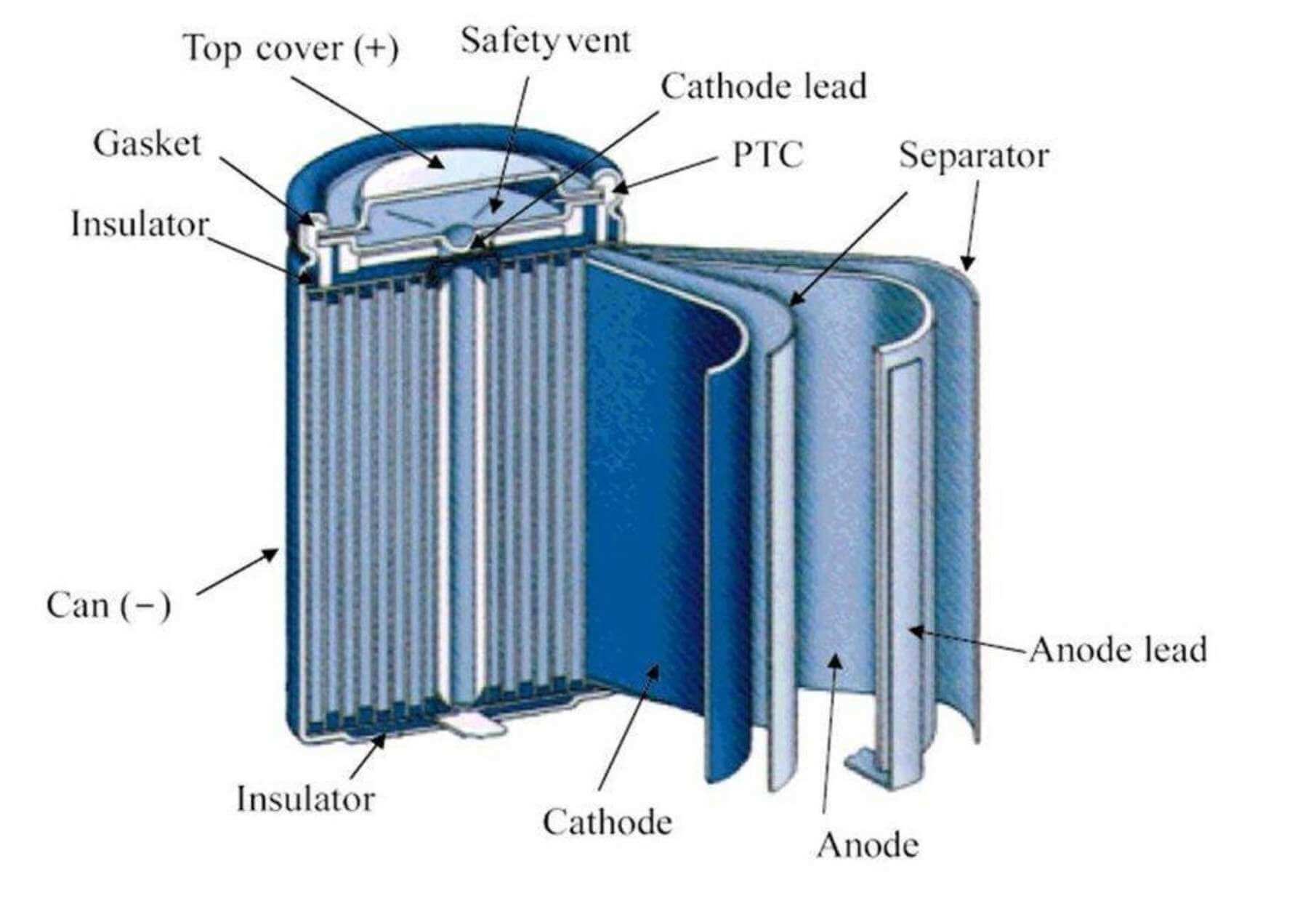

2. Mid-End: Cell Assembly

- Notching/Cutting: Electrode strips are cut or notched to create the desired electrode shape and tab geometry. Laser notching offers high precision and speed, minimizing heat affected zones.

- Stacking/Winding: For pouch or prismatic cells, electrodes and separators are carefully stacked. For cylindrical cells, they are wound. High-precision stacking or winding machines ensure precise alignment, critical for preventing short circuits and maximizing volumetric energy density. Winding tension control is paramount here.

- Tab Welding: Electrode tabs are welded to current collectors. Ultrasonic or laser welding techniques ensure low resistance and robust connections.

- Pouch/Can Forming & Sealing: Cell components are placed into pre-formed pouches or cans. Automated sealing machines (heat sealing for pouches, crimping for cans) create an airtight environment.

- Electrolyte Filling: In a dry room environment, the precisely measured electrolyte is injected into the sealed cell. Vacuum filling ensures complete saturation of electrodes and separator.

- Degassing & Final Sealing: After initial wetting, cells are often degassed to remove residual gas generated during electrolyte filling or initial reactions, then sealed.

Advantages: The high precision and automation at these stages significantly reduce contamination risks, enhance safety, and boost throughput, directly contributing to superior battery performance and extended service life (often 5-10 years depending on application).

3. Back-End: Cell Finishing & Testing

- Formation: This critical step involves the first charge-discharge cycles, forming the Solid Electrolyte Interphase (SEI) layer on the anode. Sophisticated battery formation equipment precisely controls current and voltage profiles to optimize SEI quality, which profoundly impacts battery lifespan and safety. Multi-channel formation systems allow for parallel processing of thousands of cells.

- Aging (Degassing): Cells undergo a period of rest at controlled temperatures to allow the SEI layer to stabilize and detect self-discharge issues.

- Grading and Sorting: Cells are tested for key parameters such as Open Circuit Voltage (OCV), Internal Resistance (IR), and capacity. Automated sorting machines categorize cells based on these performance metrics, ensuring consistency for subsequent module and pack assembly.

- Module and Pack Assembly: Sorted cells are grouped into modules, then into packs, integrated with Battery Management Systems (BMS), cooling systems, and enclosures. This stage involves complex automated welding, bonding, and testing of electrical connections.

Target Industries: The comprehensive lines of lithium ion battery manufacturing equipment are indispensable for industries such as:

- Automotive (EVs & HEVs): Requiring high-volume, high-power, and ultra-safe cells.

- Renewable Energy (Grid Storage): Demanding large-scale, long-life, and cost-effective energy storage solutions.

- Consumer Electronics: Focusing on miniaturization, high energy density, and rapid charge capabilities.

- Industrial Applications: Powering heavy machinery, forklifts, and uninterrupted power supplies (UPS).

Technical Specifications & Performance Parameters of Battery Manufacturing Equipment

High-performance battery manufacturing machine is characterized by its precise control, high throughput, and robust design. Understanding the technical specifications is crucial for optimizing production lines.

Key Technical Parameters for Typical Battery Production Equipment:

| Equipment Type | Key Parameters | Typical Range/Value | Impact on Battery Performance |

|---|---|---|---|

| Slurry Mixer | Mixing Volume, Vacuum Level, Shear Rate | 50-1000 Liters, < -98 kPa, 100-300 rpm | Homogeneity of slurry, absence of air bubbles, cycle life. |

| Coater | Coating Speed, Coating Width, Coating Precision, Dry Thickness Uniformity | 1-50 m/min, 300-1200 mm, ±1-3 µm, ±1-2% | Energy density, power density, safety, internal resistance. |

| Calendering Machine | Rolling Speed, Rolling Pressure, Roller Surface Runout | 5-20 m/min, 0-2000 kN, < ±1 µm | Electrode density, adhesion, porosity, cycle life, safety. |

| Winding/Stacking Machine | Winding Speed, Alignment Accuracy, Tension Control | 3-15 cells/min (winding), 8-12 cells/min (stacking), ±0.1 mm, ±5% | Volumetric energy density, internal short risk, safety, power. |

| Formation & Grading System | Channel Count, Voltage Range, Current Range, Data Logging Frequency, Accuracy | 100-1000+, 0-5V, 0-100A, 100ms, ±0.1% F.S. | SEI quality, initial capacity, cycle life, safety, grading precision. |

The quality of materials used in the construction of lithium ion battery manufacturing equipment itself is paramount. Components in contact with corrosive slurries or electrolytes are typically made from stainless steel (e.g., SUS316L) or advanced ceramics. Precision optical systems, high-resolution sensors, and robust industrial PCs govern operations, adhering to strict testing standards like ISO/IEC 17025 for calibration and ANSI B11.20 for machine safety. The service life of such equipment, with proper maintenance, can extend well beyond 10-15 years, ensuring long-term ROI.

Technical Advantages of Modern Battery Production Equipment

Investing in state-of-the-art battery production equipment offers distinct technical advantages that directly impact profitability, product quality, and competitive positioning:

- Unmatched Precision and Repeatability: Advanced control systems (PLCs, servo motors, vision systems) ensure micron-level accuracy in coating thickness, electrode alignment, and stacking. This minimizes variations between cells, leading to longer battery life and enhanced safety.

- High Throughput and Automation: Fully automated lines dramatically increase production volumes while reducing manual labor and the associated risks of human error and contamination. This is crucial for meeting the demands of Gigafactories.

- Superior Yield Rates: Intelligent defect detection systems, real-time quality control, and optimized process parameters minimize waste and rework, significantly improving overall manufacturing yield.

- Flexibility for Diverse Chemistries and Form Factors: Modular designs and programmable parameters allow quick changeovers between different battery chemistries (e.g., NMC, LFP, solid-state precursors) and cell formats (pouch, prismatic, cylindrical), future-proofing the investment.

- Enhanced Safety and Environmental Compliance: Integrated safety interlocks, explosion-proof designs, and advanced ventilation systems protect personnel and the environment. Energy-saving features (e.g., heat recovery in drying ovens, efficient power conversion in formation systems) contribute to lower operational costs and a reduced carbon footprint.

- Data-Driven Optimization: Seamless integration with MES (Manufacturing Execution Systems) allows for comprehensive data collection and analysis, enabling continuous process improvement and predictive maintenance.

These advantages translate directly into lower production costs per kWh, higher battery performance metrics (energy density, power density, cycle life), and a faster time to market for next-generation battery technologies.

Application Scenarios & Real-World Case Studies

The versatility and critical importance of sophisticated battery manufacturing machine are best illustrated through its diverse application across various high-growth sectors.

Case Study 1: High-Volume EV Battery Production

A leading Tier 1 automotive supplier deployed a complete automated lithium ion battery manufacturing equipment line for their new Gigafactory, focusing on large-format prismatic cells for electric vehicles. The integrated solution included advanced high-speed coaters with inline defect detection, robotic stacking systems achieving ±50 µm alignment precision, and a formation and grading system with over 10,000 channels. The result was an increase in cell production capacity by 200% within two years, a reduction in material waste by 15% due to improved precision, and a consistent 98% yield rate for Grade A cells. Customer feedback highlighted the system's robust uptime (99%) and minimal maintenance requirements.

Case Study 2: Grid-Scale Energy Storage Systems (ESS)

An energy solutions provider specializing in large-scale ESS required a flexible battery production equipment line to produce high-capacity LFP pouch cells. The key challenge was to maintain precise process control over larger electrode dimensions and ensure long cycle life for stationary applications. The customized solution featured an extra-wide coater and calender, coupled with an advanced electrolyte filling system optimized for uniform wetting in larger cells. The formation equipment was designed with specialized algorithms to optimize the SEI for extended cycle life, achieving over 6,000 cycles at 80% depth of discharge, surpassing initial project requirements.

Case Study 3: Consumer Electronics & Portable Devices

For a manufacturer of high-end consumer electronics, compact and high-energy-density cells were critical. Their existing battery manufacturing equipment struggled with the required miniaturization and precision. A new line was implemented featuring ultra-precision laser cutting for electrodes, highly accurate winding machines for small cylindrical cells, and formation systems capable of rapid, precise charge/discharge profiles. This upgrade enabled the production of thinner, lighter batteries with higher capacity (a 20% increase in energy density compared to previous generations), allowing for more compact and powerful consumer devices.

Vendor Comparison & Customized Solutions for Battery Production Equipment

Selecting the right supplier for battery production equipment is a strategic decision that impacts long-term operational efficiency and product quality. Key differentiators include technological innovation, manufacturing quality, after-sales support, and customization capabilities.

Vendor Comparison Factors:

| Feature/Criterion | Tier 1 Global Innovators (e.g., Shuoding) | Specialized Niche Providers | Cost-Optimized Manufacturers |

|---|---|---|---|

| R&D Investment & Innovation | High; forefront of new technologies (e.g., dry electrode, solid-state) | Medium-High; focused on specific process advancements | Low-Medium; replication of established designs |

| Automation & Integration | Full-line, intelligent automation; Industry 4.0 ready | High automation for specific modules; integration support | Partial automation; modular components |

| Quality & Precision | Exemplary; sub-micron precision, robust componentry | Very good; high precision within their specialty | Standard; acceptable for less demanding applications |

| Customization Capabilities | Extensive; bespoke solutions for unique cell designs & capacities | Moderate; adaptations within their core product range | Limited; off-the-shelf solutions with minor modifications |

| Global Service & Support | Comprehensive global network; 24/7 remote/on-site support | Regional focus; partner-based support outside core areas | Limited; often relies on local agents or basic remote support |

| Certifications & Compliance | ISO 9001, CE, UL, SEMI-compliant; adherence to global safety standards | Generally ISO 9001, CE; country-specific certifications | Basic certifications; may require additional client verification |

Customized Solutions:

Recognizing that no two battery manufacturers have identical requirements, leading suppliers offer extensive customization for battery manufacturing machine. This includes:

- Capacity Scalability: Designing lines for specific throughput needs, from pilot-scale R&D to GWh-scale mass production.

- Cell Format Adaptation: Tailoring equipment for cylindrical, pouch, prismatic, or emerging solid-state cell designs.

- Material Compatibility: Ensuring equipment can handle various electrode materials, separators, and electrolytes.

- Cleanroom Integration: Equipment designed to meet specific cleanroom classifications (e.g., ISO Class 7) with appropriate air handling and material transfer systems.

- Integration with Existing Infrastructure: Seamless interface with existing MES, ERP, and facility utilities.

- Specific Testing Protocols: Customizing formation and grading parameters to meet unique battery performance or safety standards.

A collaborative approach between the client and supplier during the design and engineering phase is crucial to developing a tailored battery production equipment solution that aligns perfectly with production goals and future expansion plans.

Ensuring : Authoritativeness, Expertise, Experience, and Trustworthiness

In the highly specialized field of lithium ion battery manufacturing equipment, selecting a partner who demonstrates exceptional Expertise, Experience, Authoritativeness, and Trustworthiness () is paramount.

Authoritativeness and Expertise:

- Certifications: Our products and manufacturing processes adhere to international standards such as ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and CE marking for European safety compliance.

- Industry Leadership: With over two decades of dedicated experience in advanced machinery, our engineering teams consist of specialists in material science, mechatronics, and automation, constantly pushing the boundaries of battery production equipment technology.

- Key Partnerships: We collaborate with leading research institutions and material suppliers to integrate the latest advancements into our equipment designs. Our client roster includes some of the largest battery manufacturers and automotive OEMs globally, a testament to our proven capabilities.

Experience:

- Proven Track Record: We have successfully delivered and commissioned dozens of full-scale battery production lines and hundreds of individual machines worldwide. Our extensive project portfolio spans diverse battery chemistries and applications, from compact consumer cells to large format EV and ESS batteries.

- Customer Feedback: Clients consistently praise our equipment for its reliability, precision, and ease of integration. Testimonials often highlight significant improvements in yield rates (e.g., 5-10% increase in Grade A cells) and reductions in operational expenditure (e.g., 10-15% lower energy consumption for certain processes).

Trustworthiness:

Building lasting partnerships is founded on transparency and reliable support.

Frequently Asked Questions (FAQ):

A: Lead times vary based on the level of customization and the complexity of the line. For standard configurations, it can range from 6 to 12 months. Highly customized solutions or Gigafactory-scale lines may require 12-18 months for design, manufacturing, and commissioning.

A: We provide a comprehensive 1-2 year warranty on all battery manufacturing equipment components, covering defects in material and workmanship. Our after-sales support includes 24/7 remote technical assistance, scheduled preventative maintenance services, on-site troubleshooting by expert engineers, and a readily available inventory of spare parts to minimize downtime.

A: Yes, our R&D team continuously works on adapting our equipment for next-generation chemistries. Many of our core processes are designed with flexibility, and we offer customized solutions to accommodate specific material handling and processing requirements for solid-state electrolytes, sodium-ion active materials, and other advanced formulations.

A: Our experienced field service engineers oversee the entire installation and commissioning process. This includes mechanical setup, electrical connections, software integration, initial calibration, trial runs, and comprehensive training for your operational and maintenance staff. A detailed project plan ensures smooth execution and rapid ramp-up to full production capacity.

Conclusion: Powering the Future with Precision Manufacturing

The global shift towards electrification and sustainable energy places battery production equipment at the forefront of technological innovation. As the demand for higher performance, safer, and more cost-effective batteries continues to accelerate, the sophistication and reliability of manufacturing machinery become increasingly critical. Investing in advanced, highly automated, and precision-engineered battery production solutions is not merely an expenditure but a strategic imperative that ensures competitive advantage, operational excellence, and a robust pathway to meeting future energy demands. By leveraging cutting-edge technology, embracing customization, and partnering with experienced suppliers, manufacturers can build the scalable, efficient, and high-quality battery production lines essential for powering tomorrow's world.

References

- Grand View Research. (2023). Lithium-Ion Battery Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/lithium-ion-battery-market

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems — Requirements.

- Battery Council International (BCI). (2022). Industry Standards and Specifications.

- MIT Technology Review. (2023). The future of battery manufacturing. Retrieved from https://news.mit.edu/topic/batteries

- U.S. Department of Energy. (2023). Battery Manufacturing. Retrieved from https://www.energy.gov/eere/vehicles/battery-manufacturing

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025

Advanced Battery Production Equipment for Efficient Manufacturing

The Foundation of Future Energy: Advanced Battery Production Equipment

In an era defined by the rapid transition towards sustainable energy, the demand for high-performance and reliable batteries is skyrocketing. This unprecedented growth necessitates cutting-edge battery production equipment that can meet stringent quality, efficiency, and scalability requirements. From electric vehicles (EVs) and grid-scale energy storage systems (ESS) to consumer electronics, the quality and cost-effectiveness of battery cells are directly influenced by the sophistication of the manufacturing machinery employed. This comprehensive overview delves into the critical aspects of battery manufacturing, exploring the intricate process flows, technical specifications, strategic advantages, and the pivotal role of advanced machinery in shaping the future of energy storage.

The journey of a battery cell, from raw material to a fully functional energy storage unit, is a complex sequence of highly precise operations. Each stage, from electrode material preparation to cell formation and testing, relies on specialized machinery designed for accuracy, throughput, and reliability. This document aims to provide B2B decision-makers and technical engineers with a deep understanding of the capabilities and considerations when investing in state-of-the-art battery manufacturing solutions.

Industry Trends Shaping Battery Manufacturing Equipment

The battery industry is in a perpetual state of innovation, driven by advancements in materials science, increasing energy density demands, and the global push for decarbonization. Several key trends are profoundly impacting the development and deployment of battery production equipment:

- Automation and Industry 4.0 Integration: The shift towards fully automated, intelligent production lines is paramount. This includes robotics, AI-driven process optimization, real-time data analytics, and predictive maintenance to maximize uptime and efficiency.

- Sustainability and Circular Economy: Equipment is increasingly designed to reduce energy consumption, minimize waste, and enable easier recycling of materials. This extends to process water treatment and solvent recovery systems.

- Advanced Battery Chemistries and Form Factors: The emergence of solid-state batteries, sodium-ion batteries, and new cell designs (e.g., large prismatic, blade batteries, 4680 cylindrical cells) necessitates flexible and adaptable lithium battery manufacturing machine designs.

- Enhanced Safety Protocols: Given the inherent risks associated with high-energy materials, advanced safety features, robust process controls, and fire suppression systems are integral to modern equipment design.

- Increased Production Scale: Gigafactories demand equipment with higher throughput, greater reliability, and seamless integration capabilities to achieve economies of scale.

According to recent market analysis, the global lithium-ion battery market size was valued at USD 57.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 19.3% from 2023 to 2030, driven predominantly by the automotive sector. This robust growth directly translates into an escalating demand for sophisticated battery manufacturing equipment capable of producing high-quality cells at unprecedented volumes.

Comprehensive Process Flow of Battery Production Equipment Lines

The manufacturing of lithium-ion batteries is a multi-stage process, each requiring specialized battery manufacturing machine to ensure precision and quality. The entire line can be broadly categorized into front-end, mid-end, and back-end processes.

1. Front-End: Electrode Preparation

- Slurry Mixing: Active materials (e.g., LiNMC, LFP for cathode; graphite for anode), conductive additives, and binders are precisely mixed with solvents to create a homogeneous slurry. This stage demands high-shear mixers and vacuum degassers to prevent air bubbles, critical for electrode performance.

- Coating: The slurry is precisely coated onto current collectors (aluminum foil for cathode, copper foil for anode). High-precision coaters (e.g., slot die coater) ensure uniform thickness and consistent active material loading. Key parameters like coating gap, speed, and tension are meticulously controlled.

- Drying: Coated foils pass through multi-zone ovens to evaporate solvents. Controlled temperature profiles and airflow are crucial to prevent cracking and ensure proper adhesion.

- Calendering: The dried electrodes are compressed between rollers to achieve desired thickness and density. Calendering machines must provide uniform pressure across the width to optimize energy density and reduce internal resistance.

- Slitting: Large rolls of calendered electrodes are precisely cut into narrower strips suitable for cell assembly. Slitting machines ensure clean, burr-free edges, vital for preventing internal shorts.

Manufacturing Processes for Equipment: Components of these machines often undergo precision CNC machining, forging for robust rollers, and advanced coating techniques for wear resistance. Testing standards typically adhere to ISO 9001 for quality management and ANSI standards for machine safety.

2. Mid-End: Cell Assembly

- Notching/Cutting: Electrode strips are cut or notched to create the desired electrode shape and tab geometry. Laser notching offers high precision and speed, minimizing heat affected zones.

- Stacking/Winding: For pouch or prismatic cells, electrodes and separators are carefully stacked. For cylindrical cells, they are wound. High-precision stacking or winding machines ensure precise alignment, critical for preventing short circuits and maximizing volumetric energy density. Winding tension control is paramount here.

- Tab Welding: Electrode tabs are welded to current collectors. Ultrasonic or laser welding techniques ensure low resistance and robust connections.

- Pouch/Can Forming & Sealing: Cell components are placed into pre-formed pouches or cans. Automated sealing machines (heat sealing for pouches, crimping for cans) create an airtight environment.

- Electrolyte Filling: In a dry room environment, the precisely measured electrolyte is injected into the sealed cell. Vacuum filling ensures complete saturation of electrodes and separator.

- Degassing & Final Sealing: After initial wetting, cells are often degassed to remove residual gas generated during electrolyte filling or initial reactions, then sealed.

Advantages: The high precision and automation at these stages significantly reduce contamination risks, enhance safety, and boost throughput, directly contributing to superior battery performance and extended service life (often 5-10 years depending on application).

3. Back-End: Cell Finishing & Testing

- Formation: This critical step involves the first charge-discharge cycles, forming the Solid Electrolyte Interphase (SEI) layer on the anode. Sophisticated battery formation equipment precisely controls current and voltage profiles to optimize SEI quality, which profoundly impacts battery lifespan and safety. Multi-channel formation systems allow for parallel processing of thousands of cells.

- Aging (Degassing): Cells undergo a period of rest at controlled temperatures to allow the SEI layer to stabilize and detect self-discharge issues.

- Grading and Sorting: Cells are tested for key parameters such as Open Circuit Voltage (OCV), Internal Resistance (IR), and capacity. Automated sorting machines categorize cells based on these performance metrics, ensuring consistency for subsequent module and pack assembly.

- Module and Pack Assembly: Sorted cells are grouped into modules, then into packs, integrated with Battery Management Systems (BMS), cooling systems, and enclosures. This stage involves complex automated welding, bonding, and testing of electrical connections.

Target Industries: The comprehensive lines of lithium ion battery manufacturing equipment are indispensable for industries such as:

- Automotive (EVs & HEVs): Requiring high-volume, high-power, and ultra-safe cells.

- Renewable Energy (Grid Storage): Demanding large-scale, long-life, and cost-effective energy storage solutions.

- Consumer Electronics: Focusing on miniaturization, high energy density, and rapid charge capabilities.

- Industrial Applications: Powering heavy machinery, forklifts, and uninterrupted power supplies (UPS).

Technical Specifications & Performance Parameters of Battery Manufacturing Equipment

High-performance battery manufacturing machine is characterized by its precise control, high throughput, and robust design. Understanding the technical specifications is crucial for optimizing production lines.

Key Technical Parameters for Typical Battery Production Equipment:

| Equipment Type | Key Parameters | Typical Range/Value | Impact on Battery Performance |

|---|---|---|---|

| Slurry Mixer | Mixing Volume, Vacuum Level, Shear Rate | 50-1000 Liters, < -98 kPa, 100-300 rpm | Homogeneity of slurry, absence of air bubbles, cycle life. |

| Coater | Coating Speed, Coating Width, Coating Precision, Dry Thickness Uniformity | 1-50 m/min, 300-1200 mm, ±1-3 µm, ±1-2% | Energy density, power density, safety, internal resistance. |

| Calendering Machine | Rolling Speed, Rolling Pressure, Roller Surface Runout | 5-20 m/min, 0-2000 kN, < ±1 µm | Electrode density, adhesion, porosity, cycle life, safety. |

| Winding/Stacking Machine | Winding Speed, Alignment Accuracy, Tension Control | 3-15 cells/min (winding), 8-12 cells/min (stacking), ±0.1 mm, ±5% | Volumetric energy density, internal short risk, safety, power. |

| Formation & Grading System | Channel Count, Voltage Range, Current Range, Data Logging Frequency, Accuracy | 100-1000+, 0-5V, 0-100A, 100ms, ±0.1% F.S. | SEI quality, initial capacity, cycle life, safety, grading precision. |

The quality of materials used in the construction of lithium ion battery manufacturing equipment itself is paramount. Components in contact with corrosive slurries or electrolytes are typically made from stainless steel (e.g., SUS316L) or advanced ceramics. Precision optical systems, high-resolution sensors, and robust industrial PCs govern operations, adhering to strict testing standards like ISO/IEC 17025 for calibration and ANSI B11.20 for machine safety. The service life of such equipment, with proper maintenance, can extend well beyond 10-15 years, ensuring long-term ROI.

Technical Advantages of Modern Battery Production Equipment

Investing in state-of-the-art battery production equipment offers distinct technical advantages that directly impact profitability, product quality, and competitive positioning:

- Unmatched Precision and Repeatability: Advanced control systems (PLCs, servo motors, vision systems) ensure micron-level accuracy in coating thickness, electrode alignment, and stacking. This minimizes variations between cells, leading to longer battery life and enhanced safety.

- High Throughput and Automation: Fully automated lines dramatically increase production volumes while reducing manual labor and the associated risks of human error and contamination. This is crucial for meeting the demands of Gigafactories.

- Superior Yield Rates: Intelligent defect detection systems, real-time quality control, and optimized process parameters minimize waste and rework, significantly improving overall manufacturing yield.

- Flexibility for Diverse Chemistries and Form Factors: Modular designs and programmable parameters allow quick changeovers between different battery chemistries (e.g., NMC, LFP, solid-state precursors) and cell formats (pouch, prismatic, cylindrical), future-proofing the investment.

- Enhanced Safety and Environmental Compliance: Integrated safety interlocks, explosion-proof designs, and advanced ventilation systems protect personnel and the environment. Energy-saving features (e.g., heat recovery in drying ovens, efficient power conversion in formation systems) contribute to lower operational costs and a reduced carbon footprint.

- Data-Driven Optimization: Seamless integration with MES (Manufacturing Execution Systems) allows for comprehensive data collection and analysis, enabling continuous process improvement and predictive maintenance.

These advantages translate directly into lower production costs per kWh, higher battery performance metrics (energy density, power density, cycle life), and a faster time to market for next-generation battery technologies.

Application Scenarios & Real-World Case Studies

The versatility and critical importance of sophisticated battery manufacturing machine are best illustrated through its diverse application across various high-growth sectors.

Case Study 1: High-Volume EV Battery Production

A leading Tier 1 automotive supplier deployed a complete automated lithium ion battery manufacturing equipment line for their new Gigafactory, focusing on large-format prismatic cells for electric vehicles. The integrated solution included advanced high-speed coaters with inline defect detection, robotic stacking systems achieving ±50 µm alignment precision, and a formation and grading system with over 10,000 channels. The result was an increase in cell production capacity by 200% within two years, a reduction in material waste by 15% due to improved precision, and a consistent 98% yield rate for Grade A cells. Customer feedback highlighted the system's robust uptime (99%) and minimal maintenance requirements.

Case Study 2: Grid-Scale Energy Storage Systems (ESS)

An energy solutions provider specializing in large-scale ESS required a flexible battery production equipment line to produce high-capacity LFP pouch cells. The key challenge was to maintain precise process control over larger electrode dimensions and ensure long cycle life for stationary applications. The customized solution featured an extra-wide coater and calender, coupled with an advanced electrolyte filling system optimized for uniform wetting in larger cells. The formation equipment was designed with specialized algorithms to optimize the SEI for extended cycle life, achieving over 6,000 cycles at 80% depth of discharge, surpassing initial project requirements.

Case Study 3: Consumer Electronics & Portable Devices

For a manufacturer of high-end consumer electronics, compact and high-energy-density cells were critical. Their existing battery manufacturing equipment struggled with the required miniaturization and precision. A new line was implemented featuring ultra-precision laser cutting for electrodes, highly accurate winding machines for small cylindrical cells, and formation systems capable of rapid, precise charge/discharge profiles. This upgrade enabled the production of thinner, lighter batteries with higher capacity (a 20% increase in energy density compared to previous generations), allowing for more compact and powerful consumer devices.

Vendor Comparison & Customized Solutions for Battery Production Equipment

Selecting the right supplier for battery production equipment is a strategic decision that impacts long-term operational efficiency and product quality. Key differentiators include technological innovation, manufacturing quality, after-sales support, and customization capabilities.

Vendor Comparison Factors:

| Feature/Criterion | Tier 1 Global Innovators (e.g., Shuoding) | Specialized Niche Providers | Cost-Optimized Manufacturers |

|---|---|---|---|

| R&D Investment & Innovation | High; forefront of new technologies (e.g., dry electrode, solid-state) | Medium-High; focused on specific process advancements | Low-Medium; replication of established designs |

| Automation & Integration | Full-line, intelligent automation; Industry 4.0 ready | High automation for specific modules; integration support | Partial automation; modular components |

| Quality & Precision | Exemplary; sub-micron precision, robust componentry | Very good; high precision within their specialty | Standard; acceptable for less demanding applications |

| Customization Capabilities | Extensive; bespoke solutions for unique cell designs & capacities | Moderate; adaptations within their core product range | Limited; off-the-shelf solutions with minor modifications |

| Global Service & Support | Comprehensive global network; 24/7 remote/on-site support | Regional focus; partner-based support outside core areas | Limited; often relies on local agents or basic remote support |

| Certifications & Compliance | ISO 9001, CE, UL, SEMI-compliant; adherence to global safety standards | Generally ISO 9001, CE; country-specific certifications | Basic certifications; may require additional client verification |

Customized Solutions:

Recognizing that no two battery manufacturers have identical requirements, leading suppliers offer extensive customization for battery manufacturing machine. This includes:

- Capacity Scalability: Designing lines for specific throughput needs, from pilot-scale R&D to GWh-scale mass production.

- Cell Format Adaptation: Tailoring equipment for cylindrical, pouch, prismatic, or emerging solid-state cell designs.

- Material Compatibility: Ensuring equipment can handle various electrode materials, separators, and electrolytes.

- Cleanroom Integration: Equipment designed to meet specific cleanroom classifications (e.g., ISO Class 7) with appropriate air handling and material transfer systems.

- Integration with Existing Infrastructure: Seamless interface with existing MES, ERP, and facility utilities.

- Specific Testing Protocols: Customizing formation and grading parameters to meet unique battery performance or safety standards.

A collaborative approach between the client and supplier during the design and engineering phase is crucial to developing a tailored battery production equipment solution that aligns perfectly with production goals and future expansion plans.

Ensuring : Authoritativeness, Expertise, Experience, and Trustworthiness

In the highly specialized field of lithium ion battery manufacturing equipment, selecting a partner who demonstrates exceptional Expertise, Experience, Authoritativeness, and Trustworthiness () is paramount.

Authoritativeness and Expertise:

- Certifications: Our products and manufacturing processes adhere to international standards such as ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and CE marking for European safety compliance.

- Industry Leadership: With over two decades of dedicated experience in advanced machinery, our engineering teams consist of specialists in material science, mechatronics, and automation, constantly pushing the boundaries of battery production equipment technology.

- Key Partnerships: We collaborate with leading research institutions and material suppliers to integrate the latest advancements into our equipment designs. Our client roster includes some of the largest battery manufacturers and automotive OEMs globally, a testament to our proven capabilities.

Experience:

- Proven Track Record: We have successfully delivered and commissioned dozens of full-scale battery production lines and hundreds of individual machines worldwide. Our extensive project portfolio spans diverse battery chemistries and applications, from compact consumer cells to large format EV and ESS batteries.

- Customer Feedback: Clients consistently praise our equipment for its reliability, precision, and ease of integration. Testimonials often highlight significant improvements in yield rates (e.g., 5-10% increase in Grade A cells) and reductions in operational expenditure (e.g., 10-15% lower energy consumption for certain processes).

Trustworthiness:

Building lasting partnerships is founded on transparency and reliable support.

Frequently Asked Questions (FAQ):

A: Lead times vary based on the level of customization and the complexity of the line. For standard configurations, it can range from 6 to 12 months. Highly customized solutions or Gigafactory-scale lines may require 12-18 months for design, manufacturing, and commissioning.

A: We provide a comprehensive 1-2 year warranty on all battery manufacturing equipment components, covering defects in material and workmanship. Our after-sales support includes 24/7 remote technical assistance, scheduled preventative maintenance services, on-site troubleshooting by expert engineers, and a readily available inventory of spare parts to minimize downtime.

A: Yes, our R&D team continuously works on adapting our equipment for next-generation chemistries. Many of our core processes are designed with flexibility, and we offer customized solutions to accommodate specific material handling and processing requirements for solid-state electrolytes, sodium-ion active materials, and other advanced formulations.

A: Our experienced field service engineers oversee the entire installation and commissioning process. This includes mechanical setup, electrical connections, software integration, initial calibration, trial runs, and comprehensive training for your operational and maintenance staff. A detailed project plan ensures smooth execution and rapid ramp-up to full production capacity.

Conclusion: Powering the Future with Precision Manufacturing

The global shift towards electrification and sustainable energy places battery production equipment at the forefront of technological innovation. As the demand for higher performance, safer, and more cost-effective batteries continues to accelerate, the sophistication and reliability of manufacturing machinery become increasingly critical. Investing in advanced, highly automated, and precision-engineered battery production solutions is not merely an expenditure but a strategic imperative that ensures competitive advantage, operational excellence, and a robust pathway to meeting future energy demands. By leveraging cutting-edge technology, embracing customization, and partnering with experienced suppliers, manufacturers can build the scalable, efficient, and high-quality battery production lines essential for powering tomorrow's world.

References

- Grand View Research. (2023). Lithium-Ion Battery Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/lithium-ion-battery-market

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems — Requirements.

- Battery Council International (BCI). (2022). Industry Standards and Specifications.

- MIT Technology Review. (2023). The future of battery manufacturing. Retrieved from https://news.mit.edu/topic/batteries

- U.S. Department of Energy. (2023). Battery Manufacturing. Retrieved from https://www.energy.gov/eere/vehicles/battery-manufacturing

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025