Automated Battery Production Equipment Increases Output Capacity

In the fast-evolving landscape of battery manufacturing, the demand for higher output capacity has never been greater. Xingtai Shuoding Trading Co., Ltd. is at the forefront of meeting this demand with its advanced battery production equipment solutions. Our automated systems are designed to streamline production processes, reduce downtime, and significantly boost output while maintaining the highest quality standards. With a focus on innovation and reliability, we provide comprehensive solutions that empower manufacturers to scale their operations efficiently.

Xingtai Shuoding Trading Co., Ltd.’s Expertise in Automated Battery Production Equipment

Xingtai Shuoding Trading Co., Ltd. has established a strong reputation as a leading provider of automated battery production equipment. With years of industry experience, our team of experts understands the intricate requirements of battery manufacturing. We specialize in designing and delivering turnkey solutions that integrate seamlessly with existing production setups. Our lithium battery machine offerings, combined with advanced battery formation equipment, are engineered to maximize output capacity while ensuring precision and consistency in every production cycle.

The Role of Battery Formation Equipment in Enhancing Output

- Our battery formation equipmentplays a crucial role in increasing production output.

- This equipment is designed to efficiently activate and test batteries, a critical step in the manufacturing process.

- The automated systems we offer can handle large volumes of batteries simultaneously, reducing the time required for formation and testing.

- By integrating battery formation equipmentinto the production line, manufacturers can significantly speed up the final stages of battery production.

- This leads to a substantial increase in overall output capacity.

|

Battery Type |

Laboratory Line Details |

Pilot/Production Line Details |

Additional Information |

|

Pūtau Prismatic |

Prismatic Cell Laboratory Line: 20 Pcs/day |

Prismatic Cell Pilot Line: 100 MWH/year |

Turnkey Solution |

|

Pouch Cell |

Pouch Cell Laboratory Line: Manual coater, Stacking machine, Sealing machine, Ultrasonic welder |

Pouch Cell Production Line: Auto Stacking machine, Slot die coater, Hydraulic calendar, Forming machine |

Flexible, lightweight rechargeable battery. High energy density, flexible form factor, etc. Preferred for portable electronics, EVs, and renewable energy systems. |

|

Cylindrical Cell |

Cylindrical Cell Laboratory Line: Manual coater, Roller press machine, winding machine. 18650 26650 21700 32650 Cylindrical Cell Laboratory Fabrication Plant. |

Automatic 18560 21700 32650 26650 Etc Cylindrical Cell Production Line/Lithium Cylindrical Battery Production Plant |

- |

Advanced Lithium Battery Machines for High-Volume Production

- Xingtai Shuoding Trading Co., Ltd.’s lithium battery machinesolutions are tailored for high-volume production environments.

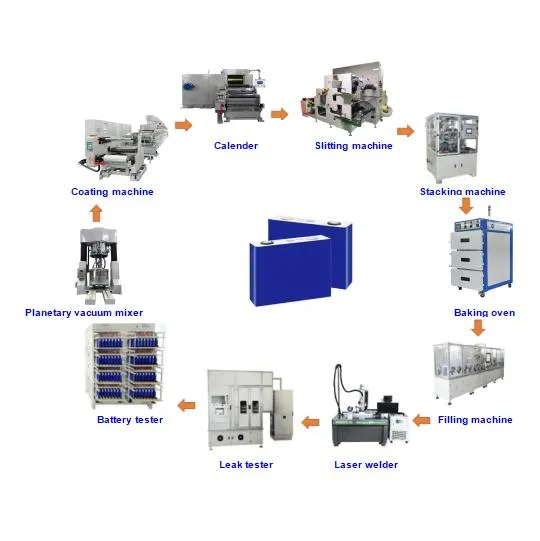

- From mixing and coating to slitting and stacking, our automated machines handle each production step with precision and speed.

- For instance, our slot die coaters and calenders ensure uniform electrode production, while auto stacking machines and welding systems streamline cell assembly.

- These lithium battery machinesolutions are designed to minimize manual intervention, reduce errors, and enable continuous operation.

- All of these features contribute to higher output capacity.

Turnkey Battery Production Equipment Solutions for Scalability

As a trusted provider of battery production equipment, we offer turnkey solutions that are fully scalable to meet growing production needs. Whether it’s a laboratory line, pilot line, or full-scale production line, our systems can be customized to match specific output requirements. For example, our prismatic cell production lines are available in capacities ranging from a small laboratory line to a large-scale production line, demonstrating our commitment to providing scalable battery production equipment that grows with your business.

Battery Production Equipment FAQS

How does automated battery production equipment increase output capacity?

Xingtai Shuoding Trading Co., Ltd.’s automated battery production equipment increases output capacity through advanced automation and efficient processes. Our equipment can handle large volumes of materials and batteries simultaneously, reducing the time per unit. Automated systems also minimize human error and downtime, allowing for continuous operation. By streamlining each production step, from mixing to testing, our battery production equipment enables manufacturers to produce more units in less time.

What role does battery formation equipment play in high-volume production?

Our battery formation equipment is essential for high-volume production as it efficiently activates and tests batteries in bulk. The automated systems can process numerous batteries at once, significantly speeding up the formation and testing stages. This reduces the bottleneck typically associated with these critical steps, allowing manufacturers to increase their overall output. The precision of our battery formation equipment also ensures consistent quality, even at high production volumes.

Can lithium battery machines be customized for specific output needs?

Yes, our lithium battery machine solutions can be fully customized to meet specific output needs. We understand that each manufacturer has unique requirements, so we offer scalable solutions. Whether you need a small laboratory line or a large-scale production line, our team will design and integrate lithium battery machine systems that match your desired output capacity. This customization ensures optimal efficiency and productivity for your specific operations.

What maintenance is required for automated battery production equipment?

Maintenance for our automated battery production equipment is designed to be minimal and straightforward. Regular inspections and cleaning of key components, such as rollers and blades, are recommended to ensure smooth operation. Our equipment also features diagnostic systems that alert operators to potential issues, allowing for proactive maintenance. As a provider, we offer comprehensive maintenance guidelines and ongoing support to keep your battery production equipment and lithium battery machine systems operating at peak performance.

How do the turnkey solutions ensure battery production equipment scaling?

Our turnkey battery production equipment solutions ensure seamless production scaling through modular and flexible designs. We start by understanding your current and future production goals, then design a system that can be expanded incrementally. Whether adding more machines or integrating additional processes, our turnkey solutions are built to grow with your business. This approach allows manufacturers to scale their operations without major overhauls, ensuring a smooth transition to higher output capacity.

Tiria

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeRongorongoNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseRongorongoNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyRongorongoNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseRongorongoNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileRongorongoNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedRongorongoNov.10,2025