Automated Car & EV Battery Production Lines

The Advanced Frontier of EV Battery Production: A Deep Dive into LFP/NMC/LTO Lines

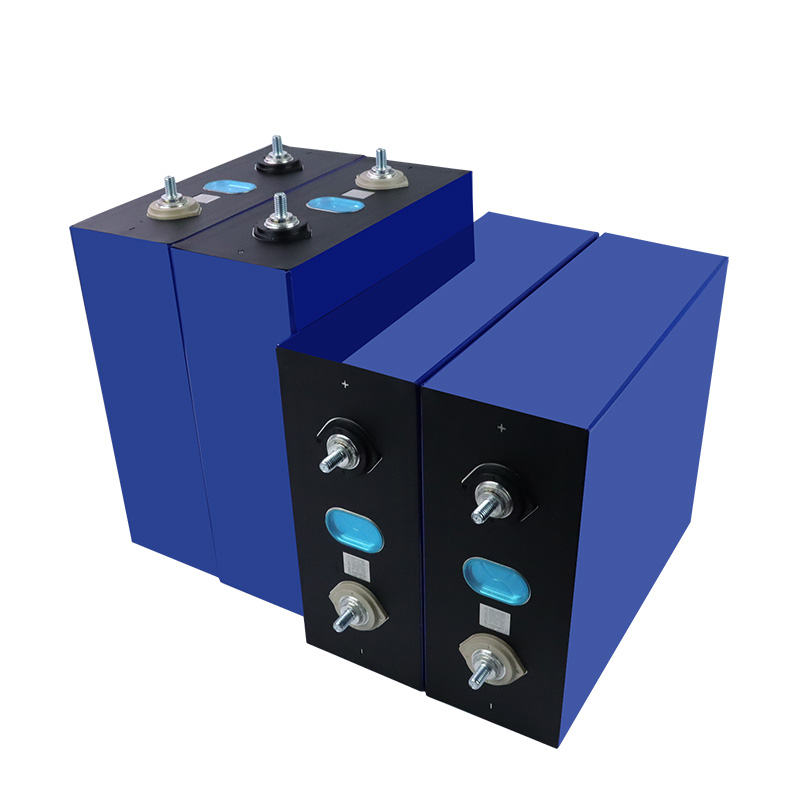

In an era defined by rapid energy transition and the burgeoning adoption of electric vehicles (EVs) alongside sophisticated energy storage systems (ESS), the manufacturing backbone—specifically the car battery production line—has become a pivotal driver of innovation and industrial efficiency. This complex ecosystem of automated processes, precision machinery, and intelligent control systems is meticulously engineered to meet the escalating global demand for high-performance, reliable, and cost-effective battery solutions. The transition from internal combustion engines to electric powertrains, coupled with the imperative for grid stabilization and renewable energy integration, places unprecedented emphasis on advancements in battery chemistries such as Lithium Iron Phosphate (LFP), Nickel Manganese Cobalt (NMC), and Lithium Titanate Oxide (LTO). Our comprehensive production lines are designed to handle capacities ranging from 30Ah to 200Ah, offering unparalleled versatility for diverse applications. Understanding the intricate mechanics and strategic advantages of these production facilities is paramount for industry stakeholders looking to scale operations, enhance product quality, and achieve competitive superiority in a fiercely evolving market landscape. These lines are not merely assembly plants; they are sophisticated centers of technological confluence, integrating advanced robotics, artificial intelligence, and real-time data analytics to ensure optimal throughput and defect prevention, thereby delivering superior products ready for the most demanding applications across the automotive, grid-scale energy storage, and specialized industrial sectors. The precision required at every stage, from raw material handling to final cell formation, necessitates robust engineering and unwavering adherence to global manufacturing benchmarks, establishing a new paradigm for industrial excellence.

The global shift towards sustainable energy solutions has significantly accelerated the evolution of battery manufacturing, transforming it into a high-tech sector characterized by continuous innovation and automation. Historically, battery production involved more manual processes, but today, an advanced car battery production line embodies state-of-the-art engineering, leveraging industrial IoT (IIoT) and advanced robotics to achieve unprecedented levels of precision and efficiency. The demand for higher energy density, faster charging capabilities, and extended cycle life has propelled research and development into chemistries like LFP, known for its safety and longevity, NMC for its energy density and power, and LTO for its ultra-fast charging and exceptional cycle life, even in extreme temperatures. These advancements directly influence the design and operation of manufacturing lines, requiring highly specialized equipment for precise electrode coating, advanced cell stacking or winding, meticulous electrolyte filling under ultra-dry conditions, and sophisticated cell formation processes. Manufacturers are now focused on building gigafactories that can produce batteries at immense scales while maintaining stringent quality control, driven by the global push for carbon neutrality and the electrification of transportation. This industrial transformation is also redefining supply chains, emphasizing localized production and resource efficiency, making the choice of a robust and adaptable battery production solution critical for companies aiming to lead in the new energy economy. The convergence of material science, mechanical engineering, and artificial intelligence within these production environments ensures that each battery cell meets rigorous performance specifications, providing the reliability and safety demanded by end-users in critical applications.

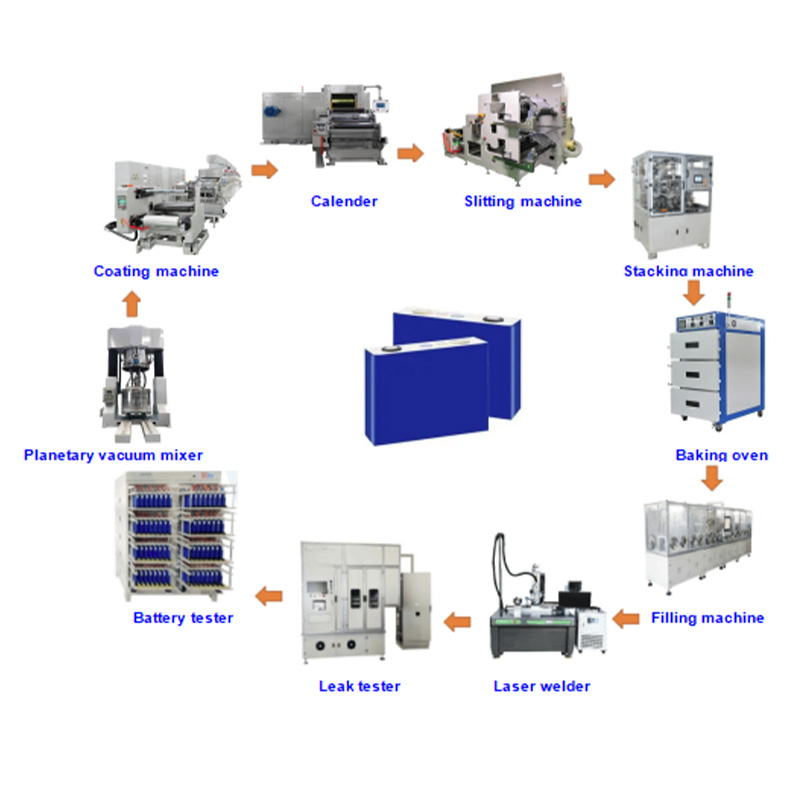

Detailed Process Flow of a Modern Car Battery Production Line

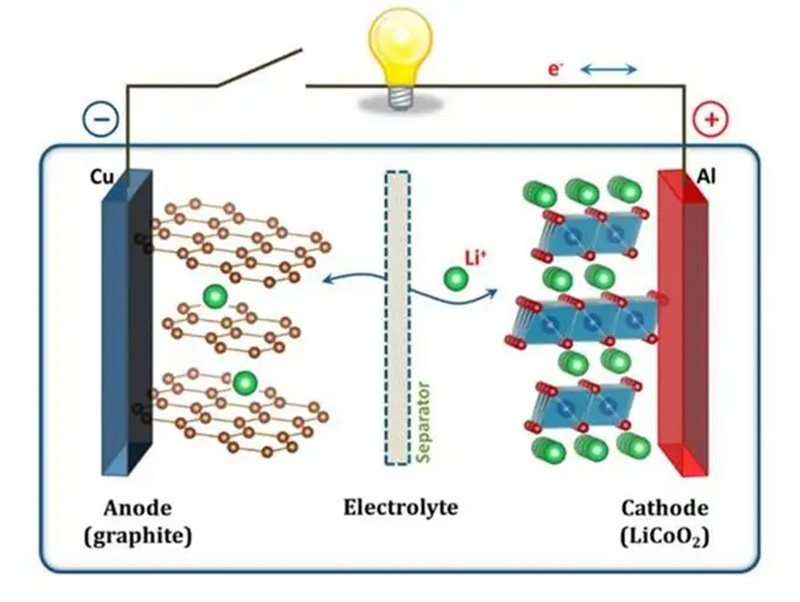

The manufacturing of an EV battery is an intricate multi-stage process that demands extreme precision and controlled environments, distinguishing it significantly from conventional industrial assembly. A state-of-the-art car battery production line typically commences with electrode preparation, a critical phase involving the mixing of active materials (e.g., LFP, NMC for cathodes; graphite for anodes), conductive agents, and binders into a slurry. This slurry is then meticulously coated onto thin metal foils—aluminum for cathodes and copper for anodes—using high-precision coating machines to ensure uniform thickness and density, which are vital for battery performance and longevity. Following coating, the electrodes undergo calendering, a compression process that enhances material density and adhesion, and then slitting, where large rolls of coated material are cut into precise widths to match the cell design. This preparatory stage sets the foundational quality for the subsequent cell assembly. Material selection adheres to stringent standards, often including ISO and ASTM specifications for purity and mechanical properties, ensuring that components can withstand the complex electrochemical reactions within the battery. The careful management of each micro-layer and composition during these early stages directly impacts the battery's energy density, power output, and overall cycle life, making precision engineering indispensable.

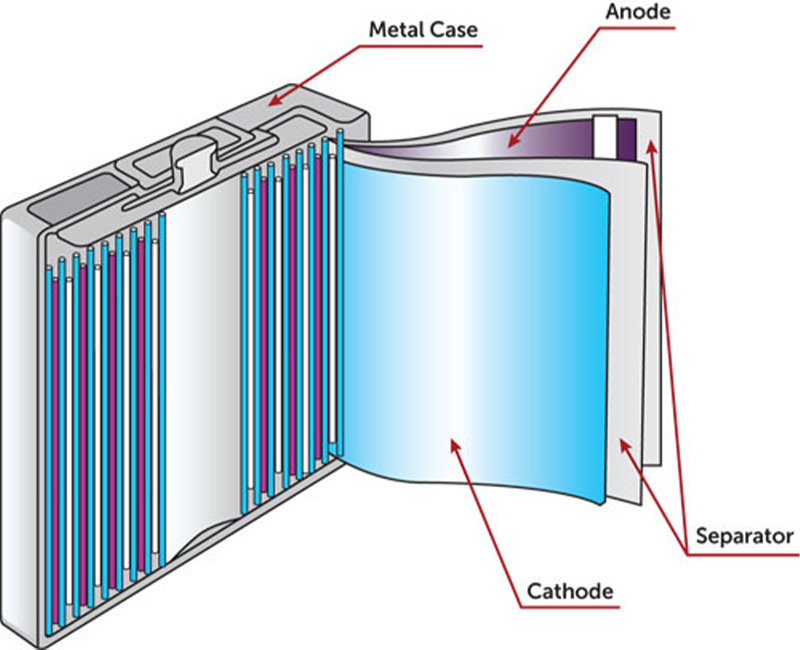

The subsequent phase, cell assembly, occurs in highly controlled dry rooms with extremely low dew points to prevent moisture contamination, which is detrimental to lithium-ion battery performance. This stage involves the precise alignment and stacking or winding of the prepared anode, cathode, and separator layers. For prismatic cells, stacking machines intricately layer the electrodes, while cylindrical or pouch cells often utilize winding machines. Following the layering, tab welding connects the electrode tabs to the cell terminals, a process requiring high-precision laser welding or ultrasonic welding to ensure robust electrical connections without damaging the delicate materials. The assembled cell is then carefully packaged, typically within an aluminum foil pouch or a metal can, before electrolyte filling. Electrolyte filling is performed under vacuum conditions to thoroughly impregnate the porous electrode structures. Post-filling, the cells are sealed hermetically, often through heat sealing for pouch cells or crimping/laser welding for cylindrical and prismatic cells. Throughout these stages, continuous in-line inspection, including Automated Optical Inspection (AOI) and X-ray analysis, is performed to detect any minute defects, ensuring structural integrity and material consistency. This rigorous adherence to quality control benchmarks, frequently aligned with IATF 16949 standards for automotive components, guarantees product reliability and safety for applicable industries such as electric vehicles, stationary energy storage, and specialized industrial equipment. The sophisticated machinery employed ensures a consistent service life, often exceeding 5,000 cycles for LFP batteries, by minimizing internal stress and material degradation.

The final crucial stages in a ev battery assembly line are cell formation, aging, and module/pack assembly. Cell formation is the initial charging and discharging cycle that activates the battery's electrochemical properties, creating the Solid Electrolyte Interphase (SEI) layer on the anode surface, which is fundamental for long-term stability and performance. This process is meticulously controlled, with precise current and voltage profiles applied to each cell, and extensive data is collected to monitor critical parameters like internal resistance and capacity. After formation, cells undergo an aging period, allowing their characteristics to stabilize and any dormant defects to manifest before final testing. This "burn-in" period ensures that only stable and high-performing cells proceed to the next stage. Passed cells are then graded based on their performance metrics and grouped for module and pack assembly. Here, multiple cells are connected in series and parallel configurations, integrated with a sophisticated Battery Management System (BMS) for monitoring voltage, current, temperature, and state of charge. Thermal management systems (liquid cooling or air cooling) are also incorporated to maintain optimal operating temperatures, crucial for performance and safety. Final testing of the complete module or pack includes comprehensive functional tests, insulation resistance checks, and vibration tests to simulate real-world conditions. The entire process emphasizes energy efficiency and anti-corrosion materials where applicable, ensuring the longevity and robustness of the production machinery itself. This end-to-end integration, from raw material to final pack, significantly enhances the battery's performance in typical application scenarios, ensuring both safety and efficiency, making it ideal for high-demanding environments like large-scale ESS and high-performance EVs.

Key Technical Parameters & Performance Specifications for Battery Production Lines

The effectiveness of a car battery production line is quantifiable through a set of critical technical parameters that dictate its throughput, precision, and the quality of the manufactured cells. Capacity scalability, allowing for seamless transition between 30Ah, 50Ah, 100Ah, and 200Ah cell formats, is a paramount feature for manufacturers serving diverse market segments, from compact EVs to large-scale grid storage. Energy density, measured in Wh/kg (gravimetric) and Wh/L (volumetric), is directly influenced by the precise layering and compaction achieved during electrode processing, with LFP typically offering around 160-190 Wh/kg and NMC up to 250-300 Wh/kg. Power density, indicating how quickly energy can be delivered, is crucial for acceleration in EVs and rapid response in ESS, directly impacted by electrode resistance and cell design. Cycle life, the number of charge-discharge cycles a battery can withstand before significant degradation, varies greatly by chemistry; LFP cells can achieve 3,000 to 8,000 cycles at 80% Depth of Discharge (DoD), while NMC might range from 1,000 to 3,000 cycles. These metrics highlight the balance between performance and longevity. The production line's ability to maintain tight tolerances for all these parameters across millions of cells underscores its technological sophistication and efficiency. The integration of advanced diagnostics and inline measurement systems, frequently employing non-destructive testing (NDT) methodologies, ensures that each cell conforms to stringent quality benchmarks and prevents substandard products from proceeding.

| Parameter | LFP Battery Cell | NMC Battery Cell | Production Line Characteristic |

|---|---|---|---|

| Nominal Voltage | 3.2 V | 3.6-3.7 V | Adjustable for cell chemistry |

| Energy Density (Wh/kg) | 160-190 | 200-300+ | Precision coating & calendering |

| Cycle Life (cycles to 80% DoD) | 3,000-8,000+ | 1,000-3,000 | Optimized formation and aging |

| Operating Temperature (°C) | -20 to 60 | -20 to 55 | Environmental control (dry room) |

| Safety Characteristics | Excellent thermal stability, less prone to thermal runaway | Higher energy, requires robust BMS for safety | Automated inspection, fire suppression |

| Production Yield (Cells/Hour) | Varies by line capacity (e.g., 500-5000+) | Varies by line capacity (e.g., 500-5000+) | High-speed automation, MES integration |

| Automation Level | High | High | Robotics, AGVs, AI-driven QC |

Beyond the core performance metrics of the battery cells themselves, the production line's operational parameters significantly impact its economic viability and environmental footprint. Factors such as energy consumption per cell, material utilization rates, and overall production yield are critical for achieving cost-effectiveness. A highly efficient ev battery assembly line minimizes waste materials and optimizes energy usage through advanced drying ovens, regenerative braking systems on automation equipment, and efficient HVAC for dry rooms. Furthermore, the ability to rapidly switch between different battery chemistries and cell sizes (e.g., from 30Ah to 200Ah cells) adds immense flexibility, catering to evolving market demands without significant retooling. This modularity is a hallmark of modern production solutions, allowing manufacturers to adapt to shifts in consumer preference or technological advancements. The integration of Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) systems provides real-time visibility into every stage of the production process, enabling predictive maintenance, rapid troubleshooting, and continuous process optimization. This data-driven approach not only enhances operational efficiency but also ensures adherence to international quality standards such as ISO 9001 for quality management and ISO 14001 for environmental management, reinforcing the line's capability to deliver consistently high-quality products while maintaining ecological responsibility.

Technological Advantages & Customization in Car Battery Assembly Line Solutions

The competitive edge in the global battery market is increasingly defined by the technological prowess embedded within a car battery assembly line. Advanced automation, powered by sophisticated robotics and intelligent control systems, stands as a cornerstone advantage. Robotics facilitate precision handling of delicate battery components, reducing human error and contamination risk, while simultaneously boosting throughput rates significantly. These robots perform tasks like precise electrode stacking, laser welding, and automated cell transfer with sub-millimeter accuracy, which is paramount for high-performance battery cells. Furthermore, integrated quality control mechanisms, including high-speed cameras for visual inspection, impedance spectroscopy for internal cell diagnostics, and X-ray systems for internal structural analysis, provide real-time feedback loops. This allows for immediate identification and rectification of defects, drastically reducing waste and improving overall yield. The implementation of robust Manufacturing Execution Systems (MES) and SCADA platforms provides holistic oversight of the entire production process, from raw material entry to final product dispatch. Such systems enable comprehensive data collection, traceability for every single cell, predictive maintenance scheduling, and real-time performance analytics. This level of granular control is vital for achieving operational excellence, minimizing downtime, and ensuring consistent product quality in a high-volume manufacturing environment. Energy efficiency is also engineered into the production line itself, with optimized drying processes, heat recovery systems, and smart power management reducing operational costs and environmental impact, thereby delivering significant long-term economic benefits to manufacturers.

Beyond standard capabilities, the ability to offer highly customized battery production line solutions is a significant differentiator for providers. Recognizing that no two manufacturing requirements are identical, a bespoke approach ensures that the production line seamlessly integrates with existing infrastructure, specific chemistries (LFP, NMC, LTO), desired capacities (30Ah-200Ah), and target production volumes. This customization extends to every segment of the line, from specialized mixing equipment for novel electrode materials to bespoke cell formation racks designed for particular charging protocols. For instance, a client focused on high-power LTO batteries for fast-charging applications will require different specifications for electrolyte filling and formation than one producing high-capacity LFP cells for stationary storage. Manufacturers of these lines work closely with clients to conduct detailed feasibility studies, site assessments, and simulation models to design a system that optimizes efficiency, reduces capital expenditure, and minimizes operational risks. This collaborative approach also involves integrating client-specific quality control protocols, often exceeding standard ISO/ANSI requirements, and ensuring compatibility with existing enterprise resource planning (ERP) systems for comprehensive production management. The flexibility to adapt to future technological advancements, such as solid-state batteries, is also a key consideration in modular and scalable designs, providing a future-proof investment for clients operating in this rapidly evolving industry.

Application Scenarios, Industry Authority & Client Trust

The applications for sophisticated car battery production line solutions are broad and impactful, underpinning the global transition to electric mobility and renewable energy. Foremost among these are large-scale EV manufacturing facilities, where these lines enable the mass production of prismatic, pouch, and cylindrical battery cells for electric cars, buses, trucks, and two-wheelers. Beyond automotive, these lines are instrumental in establishing and scaling up Energy Storage System (ESS) production for grid stabilization, industrial backup power, and residential energy solutions. The inherent flexibility of production lines capable of handling LFP, NMC, and LTO chemistries from 30Ah to 200Ah capacities ensures adaptability to varying market demands, from high-power applications requiring rapid charge/discharge to high-energy solutions demanding extended cycle life. Our expertise extends to supporting clients globally, facilitating their expansion into new markets and helping them achieve aggressive production targets. For instance, a recent project involved deploying a 1 GWh/year LFP battery line for a leading European bus manufacturer, resulting in a 20% reduction in production costs and a 15% increase in yield within the first year of operation, validating the line's efficiency and reliability. The successful integration of these lines across diverse industries underscores their robust design and the inherent advantages in terms of reduced operational expenditure and enhanced product performance, solidifying their role in driving industrial growth and sustainability.

Building trust and authority in the B2B battery manufacturing sector necessitates demonstrating unwavering commitment to quality, transparency, and comprehensive support. Our company's long-standing service tenure in the industry, coupled with adherence to international certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and CE certification for European market compliance, serves as a testament to our authoritative position. We also work towards IATF 16949 certification compliance for automotive-grade solutions, ensuring our lines meet the most rigorous industry standards. Collaborative partnerships with global automotive OEMs and major energy companies underscore our experience and reliability. Each project undergoes rigorous factory acceptance testing (FAT) and site acceptance testing (SAT), validated by independent third-party inspections to ensure performance matches agreed-upon specifications and operational benchmarks. Our commitment to client success extends through a robust delivery cycle, which typically involves detailed planning (1-2 months), equipment manufacturing and FAT (6-9 months), shipping (1-2 months), and on-site installation, commissioning, and training (2-4 months), ensuring a smooth and efficient transition to full-scale production. Comprehensive warranty programs, usually ranging from 1 to 3 years on core components, coupled with readily available spare parts and a global network of technical support engineers, provide peace of mind and minimize potential downtime.

Frequently Asked Questions (FAQ) About EV Battery Production Lines

Q1: What are the primary differences between LFP, NMC, and LTO battery production lines?

While the fundamental steps of electrode preparation, cell assembly, formation, and testing are common, significant differences arise in material handling, dry room requirements, and formation protocols due to the unique chemical properties of LFP, NMC, and LTO. LFP lines often require less stringent dry room conditions compared to NMC due to LFP's lower hygroscopicity, but precise coating and calendering remain crucial for both. LTO, known for its rapid charging and exceptional cycle life, demands specialized electrode materials and very specific electrolyte compositions, which impact mixing and filling processes. Moreover, the formation cycles are specifically tailored for each chemistry to optimize the Solid Electrolyte Interphase (SEI) layer, which determines the battery's long-term stability and cycle life. Our production lines are designed with modularity to accommodate these variations, allowing for configuration adjustments based on the specific chemistry being processed, ensuring optimal performance and yield regardless of the battery type. This adaptability is key for manufacturers looking to diversify their product portfolio and respond flexibly to market demands for different battery chemistries, ensuring that the initial investment in a production line can evolve with future technological shifts.

Q2: How do you ensure the quality and safety of batteries produced on your lines?

Quality and safety are paramount at every stage of our car battery production line. We integrate multiple layers of automated inspection and quality control systems. This includes precise weight and thickness measurements during electrode coating, Automated Optical Inspection (AOI) to detect surface defects, X-ray inspection for internal structural integrity, and highly accurate voltage and impedance testing at various stages of cell assembly and formation. Environmental controls, particularly ultra-low dew point dry rooms, prevent moisture ingress that can compromise battery performance and safety. Furthermore, our lines incorporate advanced MES (Manufacturing Execution Systems) for comprehensive data traceability, allowing us to track every raw material batch and process parameter for each individual cell. This enables rapid identification and isolation of any quality anomalies. All equipment adheres to international safety standards, and fire suppression systems are integrated into critical areas. Post-production, cells undergo rigorous aging and sorting based on performance grades, ensuring only the highest quality cells proceed to module and pack assembly. These stringent protocols are aligned with industry best practices and global certifications such as ISO 9001 and IATF 16949, guaranteeing superior product reliability and safety for end-users in demanding applications.

Q3: What level of customization can be expected for a specific production capacity, such as 1 GWh/year?

Our approach to production line deployment is highly customizable to meet specific capacity requirements, including large-scale outputs like 1 GWh/year or more. Customization begins with a detailed assessment of the client's target cell chemistry (LFP, NMC, LTO), cell format (pouch, prismatic, cylindrical), desired energy density, cycle life, and target production volume. Based on this, we design a tailored layout and select appropriate machinery, scaling up or down the capacity of individual process stations—from mixing and coating equipment to the number of formation channels and aging racks—to match the annual output goal. This involves optimizing equipment throughput, automation level, and facility footprint. For example, a 1 GWh line might require multiple high-speed coating machines, several winding/stacking lines, and a vast array of formation and aging test channels running simultaneously. We also customize the MES and SCADA integration to align with client-specific IT infrastructure and data management requirements, ensuring seamless operation and maximum efficiency. Our engineers collaborate closely with the client's team from initial concept to final commissioning, providing a solution that is not only technologically advanced but also perfectly aligned with their strategic business objectives and future expansion plans, guaranteeing scalability and adaptability.

Conclusion: Pioneering the Future of Battery Manufacturing

The advanced car battery production line represents the pinnacle of modern manufacturing, blending sophisticated engineering with groundbreaking material science and intelligent automation. As the global demand for electric vehicles and reliable energy storage solutions continues its exponential growth, the capability to produce high-quality, high-performance LFP, NMC, and LTO batteries ranging from 30Ah to 200Ah capacities at scale becomes indispensable for market leadership. Our comprehensive solutions embody precision, efficiency, and adaptability, ensuring that our clients can meet the rigorous demands of automotive OEMs, energy utility providers, and specialized industrial sectors. By integrating cutting-edge robotics, real-time quality control, and robust MES platforms, these production lines not only optimize throughput and yield but also uphold the highest standards of safety and environmental responsibility. We are committed to fostering innovation and supporting our partners through tailored solutions, unparalleled technical expertise, and dedicated after-sales support. Investing in a state-of-the-art battery production line is not merely an acquisition of machinery; it is a strategic partnership for future growth, empowering manufacturers to navigate the complexities of the new energy landscape with confidence and to contribute significantly to a sustainable future. The continuous evolution of battery technology necessitates a manufacturing framework that is equally dynamic and forward-thinking, positioning partners at the forefront of this transformative industrial revolution.

References

- Journal of Power Sources, "Advances in Lithium-Ion Battery Manufacturing Automation and Quality Control," Vol. 488, 2021.

- Electrochimica Acta, "Comparative Analysis of LFP, NMC, and LTO Battery Chemistries for Electric Vehicle Applications," Vol. 370, 2020.

- IEEE Transactions on Industrial Electronics, "Smart Manufacturing in Gigafactories: AI and IoT Integration in Battery Production," Vol. 68, No. 5, 2021.

- Nature Energy, "The Role of Next-Generation Battery Technologies in Achieving Global Decarbonization," Vol. 7, 2022.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025