lntroduction

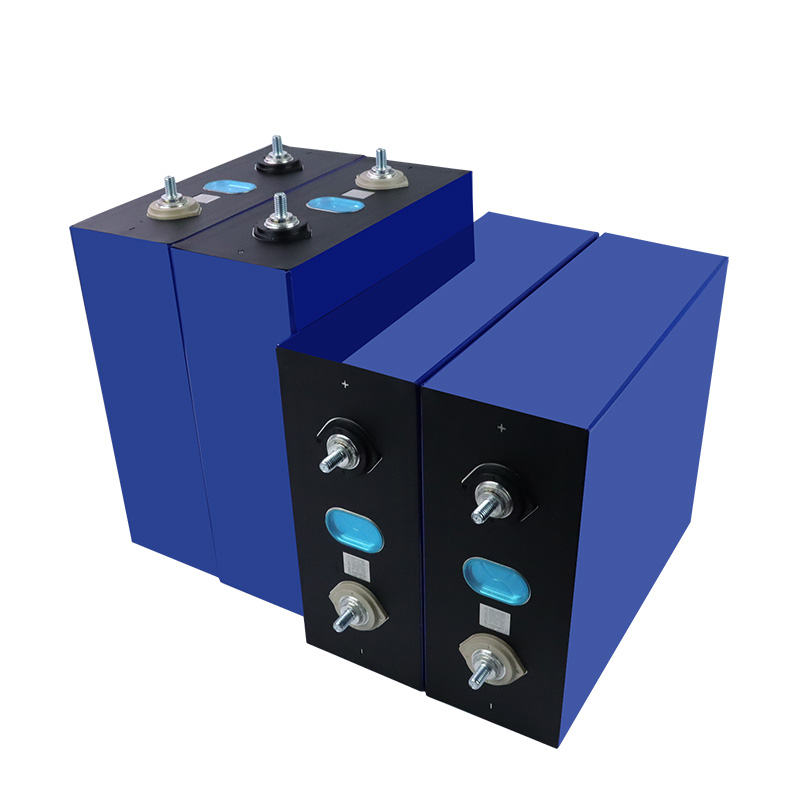

1:Prismatic Cell.

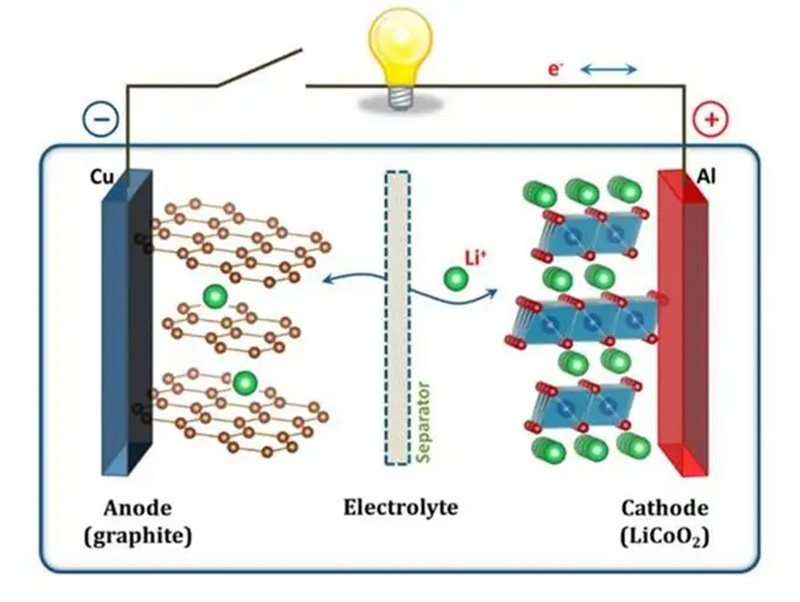

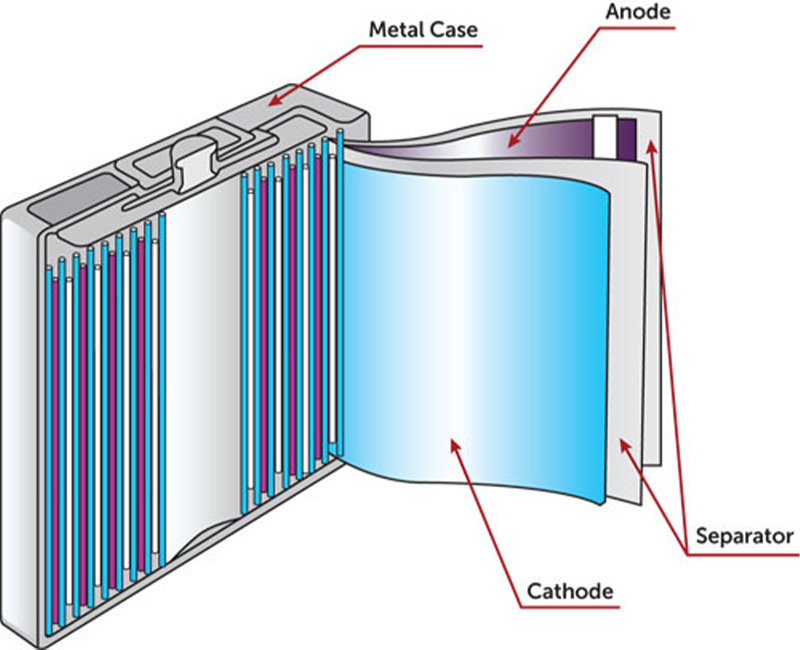

Prismatic cell is a cell whose chemistry is enclosed in a rigid casing. Its rectangular shape allows efficiently stacking multiple units in a battery module. There are two types of prismatic cells: the electrode sheets inside the casing (anode, separator, cathode) are either stacked or rolled and flattened.

For the same volume, stacked prismatic cells can release more energy at once, offering better performance, whereas flattened prismatic cells contain more energy, offering more durability.

2:The EV industry evolves quickly, and it’s uncertain whether prismatic cells or cylindrical cells will prevail. At the moment, cylindrical cells are more widespread in the EV industry, but there are reasons to think prismatic cells will gain in popularity.

First, prismatic cells offer an opportunity to drive down costs by diminishing the number of manufacturing steps. Their format makes it possible to manufacture larger cells, which reduces the number of electrical connections that need to be cleaned and welded.

Prismatic batteries are also the ideal format for the lithium-iron phosphate (LFP) chemistry, a mix of materials that are cheaper and more accessible. Unlike other chemistries, LFP batteries use resources that are everywhere on the planet. They do not require rare and expensive materials like nickel and cobalt that drive the cost of other cell types upward.

There are strong signals that LFP prismatic cells are emerging. In Asia, EV manufacturers already use LiFePO4 batteries, a type of LFP battery in the prismatic format. Tesla also stated that it has begun using prismatic batteries manufactured in China for the standard range versions of its cars.

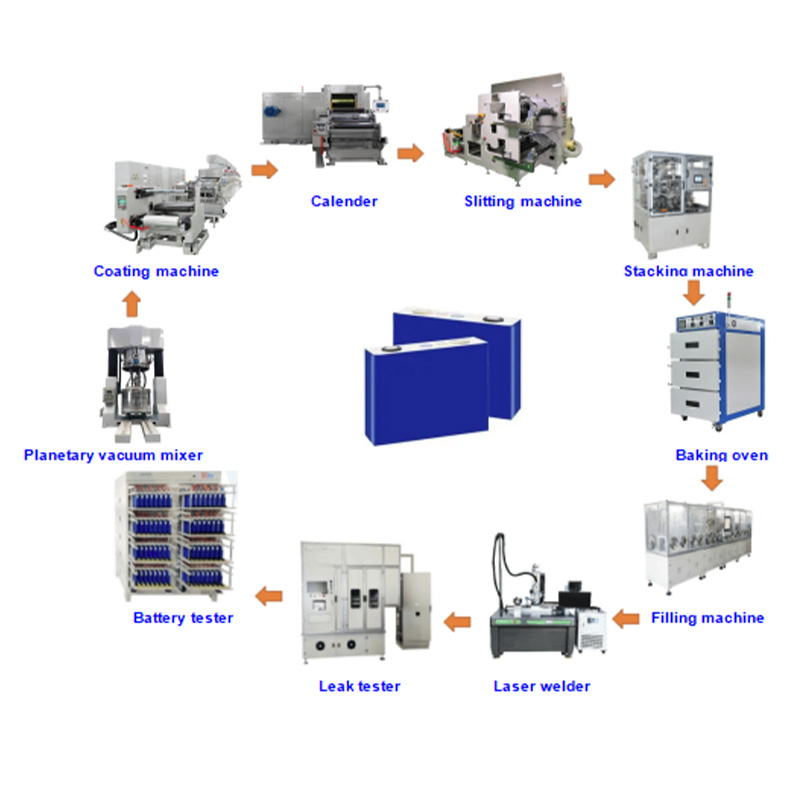

3: Equipment List.

|

SN. |

Equipment Name |

|

1 |

Mixing Equipment |

|

2 |

Feeding System |

|

3 |

Slurry Buffer Tank |

|

4 |

Auto Double Sides Slot Die Coating Machine |

|

5 |

NMP Recovery System |

|

6 |

Calender Machine |

|

7 |

Auto Slitting Machine |

|

8 |

Stamping Machine |

|

9 |

Auto Stacking Machine |

|

10 |

Ultrasonic Spot Welding Machine (Tab to lid welding) |

|

11 |

Cover Plate Welding Machine |

|

12 |

Insulator Wrapping Machine |

|

13 |

Shelling &Welding Machine |

|

14 |

Helium Testing Machine |

|

15 |

Washing Machine |

|

16 |

X-ray Tester |

|

17 |

High Vacuum Oven |

|

18 |

Auto Electrolyte Filling Machine |

|

19 |

High Temperature Wetting |

|

20 |

Negative Pressure Formation Machine |

|

21 |

Laser Welding&Sealing Machine |

|

22 |

OCV Tester |

|

23 |

Charging Machine |

|

24 |

PVC Film Pasting Machine |

|

25 |

Drying Unit |

|

26 |

Air Compressor Unit |

|

27 |

Vacuum Unit |

|

28 |

Nitrogen Generating Unit |

|

29 |

Deionized Water Machine |

|

30 |

Cooler |

|

31 |

ACIR Tester |

4: Why Choose Xingtai shuoding trading Co., Ltd?

- **Innovative Technology**: Our production lines incorporate the latest technological advancements to ensure optimal performance and reliability.

- **Customization**: We understand that each business has unique requirements. Our team can customize solutions to meet your specific production needs.

- **Support & Maintenance**: We provide comprehensive support and maintenance services to ensure your production lines operate smoothly.

- **Cost-Effectiveness**: Our solutions are designed to deliver maximum value while keeping your investments optimal.

- **Sustainability**: Our lithium battery production lines emphasize sustainability, helping you reduce your carbon footprint and contribute to a greener planet.

News