Jan . 26 , 2025 05:55

Back to list

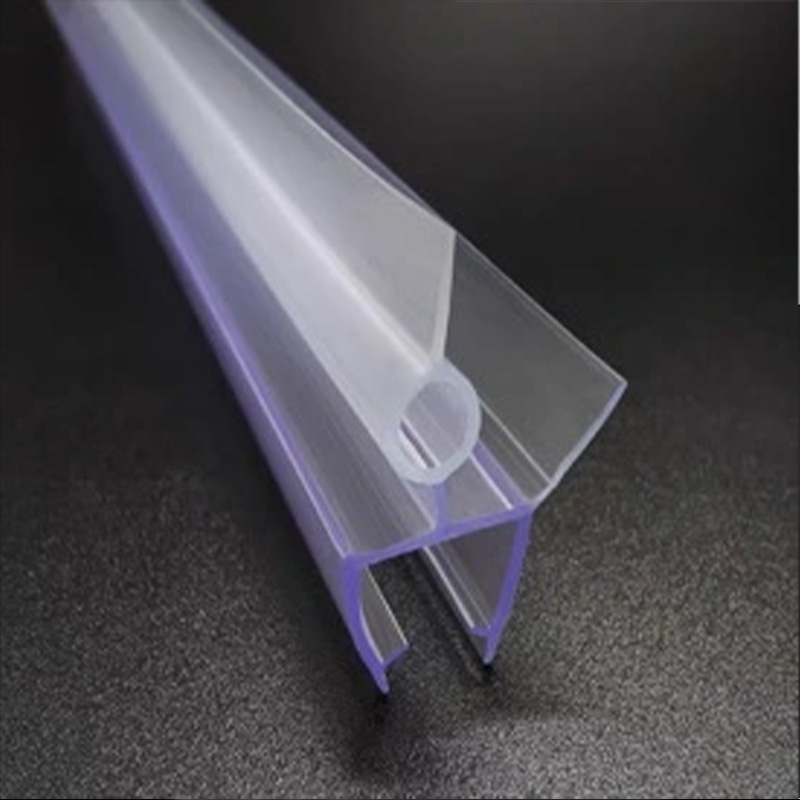

hangar door rubber seals

The intricate world of automotive engineering has many unseen heroes, and amongst them, automotive door rubber seals play an indispensable role. These components may seem ancillary, yet they significantly contribute to the overall performance, comfort, and durability of a vehicle. For car manufacturers and enthusiasts alike, understanding the nuances of these rubber seals can lead to improved vehicle maintenance and customer satisfaction.

Additionally, the technological advancements in the manufacturing of automotive seals showcase a blend of expertise and innovation. Today, seals are designed with varying cross-sections and configurations to fit the unique contours of different vehicle models. This customization ensures that each seal serves its purpose while enhancing the vehicle’s aesthetics. It is this combination of functionality and design that underscores the authority of manufacturers in producing components that meet rigorous industry standards. Trustworthiness in the automotive rubber seal market is often bolstered by adherence to stringent quality control measures and certifications. Top manufacturers subject their products to extensive testing, simulating various atmospheric conditions and mechanical stress to ascertain the seals' reliability. For consumers, this dedication to quality assurance translates to peace of mind, knowing their vehicle is equipped with components that deliver what they promise. When it comes to the user experience, feedback and reviews from car owners who have prioritized high-grade rubber seals assert the transformative impact these have on vehicle quality. An adeptly sealed cabin not only provides enhanced protection against the elements but also contributes to a higher resale value, as potential buyers note the overall condition and maintenance of the car. Therefore, car enthusiasts argue that investing in superior automotive door rubber seals pays dividends, both in terms of immediate comfort and long-term vehicle valuation. In conclusion, automotive door rubber seals, while understated, are an integral component of vehicle design that demand attention and investment. Their contribution to vehicle protection, comfort, and sustainability highlights the need for both manufacturers and consumers to focus on quality and maintenance. With continued advancements and commitment to engineering excellence, these unnoticed yet crucial components will remain resilient pillars supporting the automotive industry’s evolution.

Additionally, the technological advancements in the manufacturing of automotive seals showcase a blend of expertise and innovation. Today, seals are designed with varying cross-sections and configurations to fit the unique contours of different vehicle models. This customization ensures that each seal serves its purpose while enhancing the vehicle’s aesthetics. It is this combination of functionality and design that underscores the authority of manufacturers in producing components that meet rigorous industry standards. Trustworthiness in the automotive rubber seal market is often bolstered by adherence to stringent quality control measures and certifications. Top manufacturers subject their products to extensive testing, simulating various atmospheric conditions and mechanical stress to ascertain the seals' reliability. For consumers, this dedication to quality assurance translates to peace of mind, knowing their vehicle is equipped with components that deliver what they promise. When it comes to the user experience, feedback and reviews from car owners who have prioritized high-grade rubber seals assert the transformative impact these have on vehicle quality. An adeptly sealed cabin not only provides enhanced protection against the elements but also contributes to a higher resale value, as potential buyers note the overall condition and maintenance of the car. Therefore, car enthusiasts argue that investing in superior automotive door rubber seals pays dividends, both in terms of immediate comfort and long-term vehicle valuation. In conclusion, automotive door rubber seals, while understated, are an integral component of vehicle design that demand attention and investment. Their contribution to vehicle protection, comfort, and sustainability highlights the need for both manufacturers and consumers to focus on quality and maintenance. With continued advancements and commitment to engineering excellence, these unnoticed yet crucial components will remain resilient pillars supporting the automotive industry’s evolution.

Share

Previous:

Next:

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025