Jan . 09 , 2025 10:56

Back to list

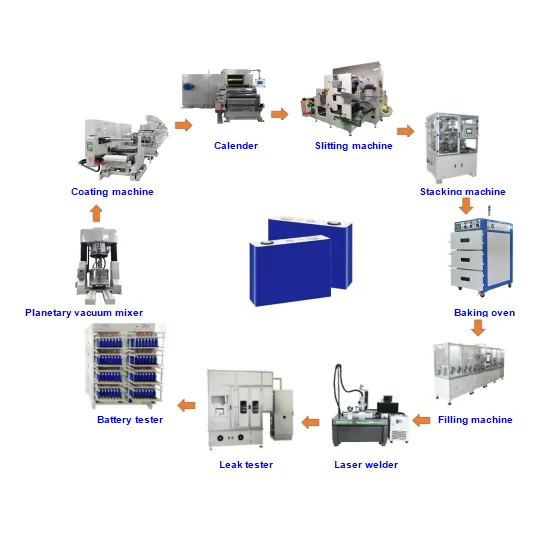

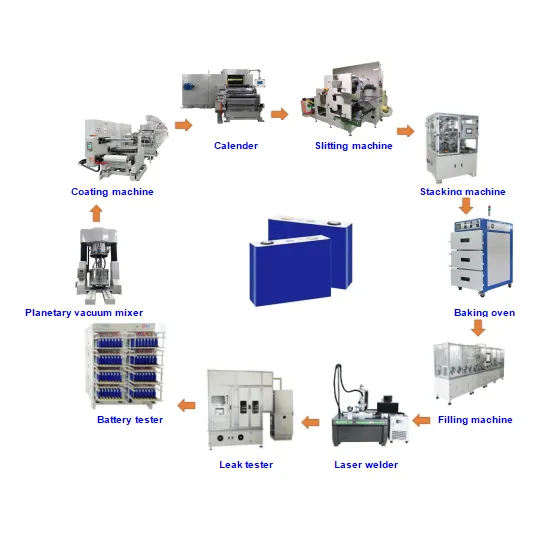

pouch cell manufacturing

Manufacturing of prismatic cell machines has seen significant advancements over recent years, fundamentally transforming the energy storage sector. These advancements can be traced back to improvements in technology that are pushing the boundaries of what is possible, leading to more efficient, reliable, and scalable production processes. Drawn from numerous industrial experiences and authority-backed insights, this article maps out the intricate journey and expert perspectives of prismatic cell manufacturing.

The authority of prismatic cell manufacturing equipment is further underscored by adherence to international safety standards and certifications, such as ISO and IEC for battery manufacturing. Consultation with certifying bodies and experienced engineers ensures that all machine components meet these rigorous standards, providing a guarantee of safety for both operators and end-users. Additionally, feedback loops and continuous improvement processes have been established based on real-world data and machine learning analytics, which help in refining operational efficiencies and curbing operational downtimes. Trustworthiness in prismatic cell manufacturing machines can't be overstated. Companies with long-standing reputations in manufacturing technology invest significantly in research and development to deliver machines that not only meet but exceed industry expectations. These machines frequently undergo rigorous testing environments that simulate extreme operational conditions, reassuring buyers of their durability and efficiency. In conclusion, the prismatic cell manufacturing machine stands as a testament to how technological innovation, coupled with industry expertise and unwavering assurance in quality, can forge tools that uphold the highest standards of efficiency and reliability. This is essential as the world rapidly shifts towards sustainable energy solutions, underscoring the immense potential and necessity of advanced industrial equipment in achieving global energy goals.

The authority of prismatic cell manufacturing equipment is further underscored by adherence to international safety standards and certifications, such as ISO and IEC for battery manufacturing. Consultation with certifying bodies and experienced engineers ensures that all machine components meet these rigorous standards, providing a guarantee of safety for both operators and end-users. Additionally, feedback loops and continuous improvement processes have been established based on real-world data and machine learning analytics, which help in refining operational efficiencies and curbing operational downtimes. Trustworthiness in prismatic cell manufacturing machines can't be overstated. Companies with long-standing reputations in manufacturing technology invest significantly in research and development to deliver machines that not only meet but exceed industry expectations. These machines frequently undergo rigorous testing environments that simulate extreme operational conditions, reassuring buyers of their durability and efficiency. In conclusion, the prismatic cell manufacturing machine stands as a testament to how technological innovation, coupled with industry expertise and unwavering assurance in quality, can forge tools that uphold the highest standards of efficiency and reliability. This is essential as the world rapidly shifts towards sustainable energy solutions, underscoring the immense potential and necessity of advanced industrial equipment in achieving global energy goals.

Share

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025