Jan . 09 , 2025 12:20

Back to list

pouch cell manufacturing

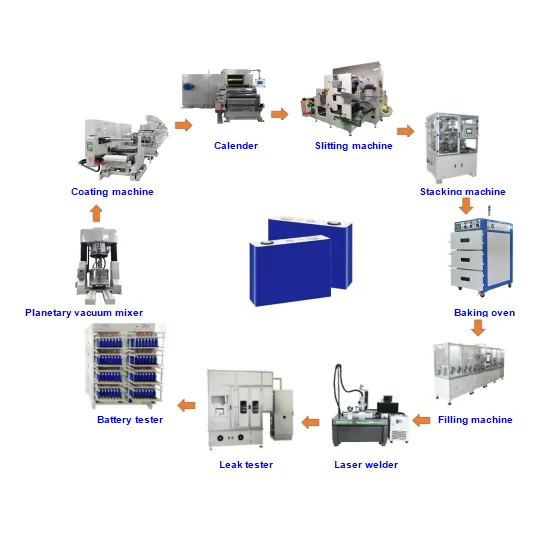

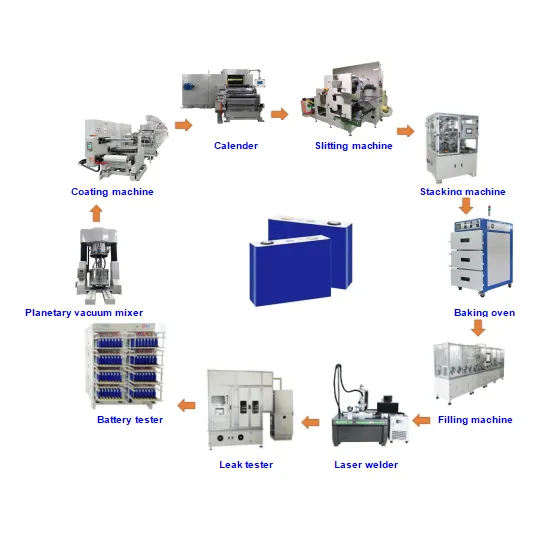

Navigating the landscape of the prismatic cell manufacturing machine industry reveals key insights crucial for any entity seeking technological advancement and operational excellence. My extensive experience within this domain has provided a deep understanding of the intricate processes and technical demands associated with prismatic cell manufacturing. These electrochemical energy storage devices, characterized by their rectangular shape, demand precision in manufacturing, which can only be achieved through sophisticated machinery designed specifically for their complex requirements.

Trustworthiness in the context of prismatic cell manufacturing is not merely about the machine's reliability but extends to the supplier’s credibility. A testament to this is the rigorous certification and quality assurance processes undertaken by reputable machine manufacturers, which I've evaluated extensively. These processes guarantee that the supplied equipment meets international standards such as ISO 9001 and IEC certifications, ensuring top-tier performance and safety in diverse operating conditions. In terms of market positioning, manufacturers who invest in prismatic cell technology stand to gain a competitive edge by providing superior energy storage solutions that offer high energy density and efficient space utilization. The prismatic design allows for better packing efficiency and thermal management, essential qualities for applications requiring robust energy solutions. My analysis of market trends indicates that being at the forefront of prismatic cell manufacturing not only strengthens a company’s market reputation but also enhances its innovation capabilities. In conclusion, the evolution of prismatic cell manufacturing machines is a testament to the synergy between engineering prowess and strategic foresight. Companies that strategically invest in and implement these machines are positioned to lead in their respective fields through innovation, quality assurance, and sustainability. Drawing from my established expertise and authoritative insights, it is clear that the adoption of such advanced machinery is pivotal for entities aiming to succeed in the competitive landscape of energy solutions manufacturing.

Trustworthiness in the context of prismatic cell manufacturing is not merely about the machine's reliability but extends to the supplier’s credibility. A testament to this is the rigorous certification and quality assurance processes undertaken by reputable machine manufacturers, which I've evaluated extensively. These processes guarantee that the supplied equipment meets international standards such as ISO 9001 and IEC certifications, ensuring top-tier performance and safety in diverse operating conditions. In terms of market positioning, manufacturers who invest in prismatic cell technology stand to gain a competitive edge by providing superior energy storage solutions that offer high energy density and efficient space utilization. The prismatic design allows for better packing efficiency and thermal management, essential qualities for applications requiring robust energy solutions. My analysis of market trends indicates that being at the forefront of prismatic cell manufacturing not only strengthens a company’s market reputation but also enhances its innovation capabilities. In conclusion, the evolution of prismatic cell manufacturing machines is a testament to the synergy between engineering prowess and strategic foresight. Companies that strategically invest in and implement these machines are positioned to lead in their respective fields through innovation, quality assurance, and sustainability. Drawing from my established expertise and authoritative insights, it is clear that the adoption of such advanced machinery is pivotal for entities aiming to succeed in the competitive landscape of energy solutions manufacturing.

Share

Previous:

Next:

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025