Jan . 10 , 2025 08:45

Back to list

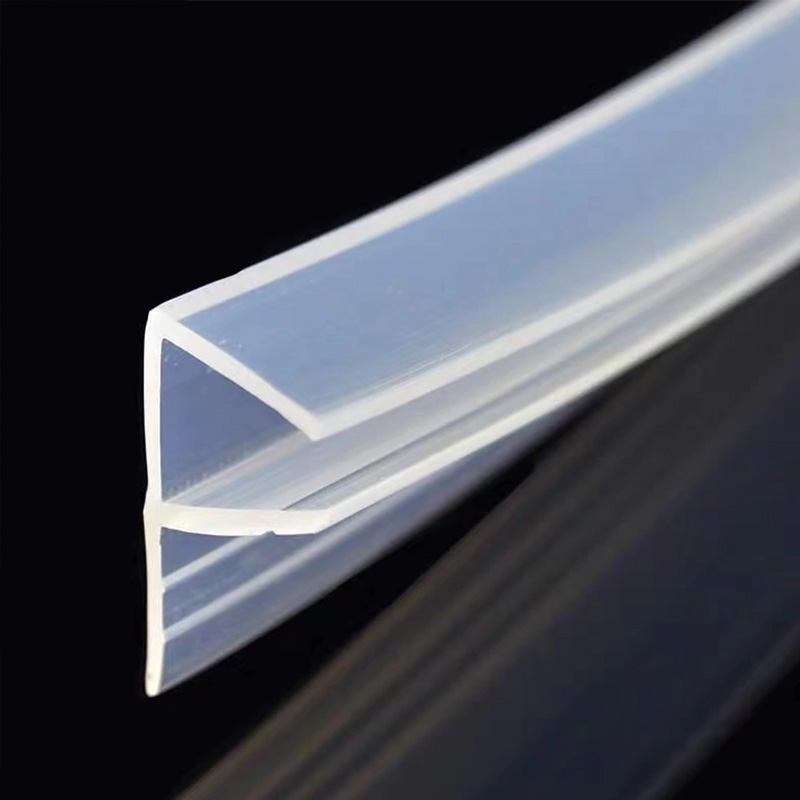

rubber seals

Rubber seals are indispensable components in a variety of industries, ranging from automotive and aerospace to plumbing and electronics. They might seem like simple products, but their function is critical, ensuring the efficiency and longevity of machinery and devices. These versatile components touch upon the four crucial pillars of Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT).

The authoritativeness of rubber seals stems from their widespread adoption across industries. They are backed by extensive standards and certifications that govern their production and application. Adhering to standards such as ISO 9001 and ASTM, manufacturers demonstrate their dedication to quality and safety. This adherence not only ensures the product's performance but also instills confidence in end-users across various sectors. For instance, aerospace companies trust these seals because they meet stringent requirements that guarantee passenger safety and craft integrity. Trustworthiness in rubber seals is built on the consistent performance and reliability they offer. Users rely on these products daily, often in high-stakes environments where equipment failure can lead to significant downtime or safety hazards. Testimonials from industry leaders and specialists highlight the dependability of rubber seals. Companies across the globe have shared success stories detailing how these seals have prevented potential disasters and sustained the smooth operation of their businesses. These endorsements are critical in establishing trust and confirming the essential role of rubber seals in maintaining operational integrity. In sum, rubber seals exemplify the essence of Experience, Expertise, Authoritativeness, and Trustworthiness. Their extensive application across different industries underscores the experience they bring to the table. The specialized knowledge employed in their manufacturing highlights the expertise that goes into their production. Industry standards and widespread use affirm their authoritativeness, while consistent, reliable performance builds the trust that professionals place in these small yet mighty components. As industries continue to evolve, the demand for quality rubber seals will undoubtedly persist, underscoring their enduring legacy as silent guardians of modern technology and infrastructure.

The authoritativeness of rubber seals stems from their widespread adoption across industries. They are backed by extensive standards and certifications that govern their production and application. Adhering to standards such as ISO 9001 and ASTM, manufacturers demonstrate their dedication to quality and safety. This adherence not only ensures the product's performance but also instills confidence in end-users across various sectors. For instance, aerospace companies trust these seals because they meet stringent requirements that guarantee passenger safety and craft integrity. Trustworthiness in rubber seals is built on the consistent performance and reliability they offer. Users rely on these products daily, often in high-stakes environments where equipment failure can lead to significant downtime or safety hazards. Testimonials from industry leaders and specialists highlight the dependability of rubber seals. Companies across the globe have shared success stories detailing how these seals have prevented potential disasters and sustained the smooth operation of their businesses. These endorsements are critical in establishing trust and confirming the essential role of rubber seals in maintaining operational integrity. In sum, rubber seals exemplify the essence of Experience, Expertise, Authoritativeness, and Trustworthiness. Their extensive application across different industries underscores the experience they bring to the table. The specialized knowledge employed in their manufacturing highlights the expertise that goes into their production. Industry standards and widespread use affirm their authoritativeness, while consistent, reliable performance builds the trust that professionals place in these small yet mighty components. As industries continue to evolve, the demand for quality rubber seals will undoubtedly persist, underscoring their enduring legacy as silent guardians of modern technology and infrastructure.

Share

Previous:

Next:

Latest news

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025