Smart AI-Enhanced Car Battery Production Line | GPT-4 Turbo

1. Market Overview: Car Battery Production Line Sector Trends

- In 2023, the global car battery production line market exceeded USD 7.5 billion (Statista, 2023), driven by EV demand.

- EV battery assembly line automation rates reached up to 92% in China and Europe, cutting labor costs by over 60% (Gartner, 2023).

- Industry shift to LFP, NMC, and LTO chemistries, balancing safety, cost, and performance for vehicles, grid, and industry storage.

- New ISO/IEC 62619:2022 and GB/T 31484 standards adopted for battery system safety and longevity.

2. Technical Comparison: Car Battery Production Line Systems

| Parameter | EV Car Battery LFP/NMC/LTO Line | Standard Car Battery Line | Advanced EV Battery Assembly Line |

|---|---|---|---|

| Cell Types Supported | LFP, NMC, LTO | AGM, Lead-Acid | LFP, NMC, LTO, Solid-State |

| Max Output (pcs/day) | 5,000 | 2,800 | 8,000 |

| Automation Level | Full (90%-98%) | Semi-auto (60%-70%) | Full (98%+robotics) |

| ISO Compliance | ISO 9001, ISO 14001 ISO/IEC 62619 |

ISO 9001 | ISO 9001, IEC 61508 |

| Customizable Battery Format | 30Ah/50Ah/100Ah/200Ah | ≤ 60Ah | 20Ah-500Ah |

| QC Standard | AQL 0.4 (ANSI/ASQ Z1.4) | AQL 1.0 | AQL 0.25 |

| Smart MES Integration | YES | NO | YES + AI |

| Production Line Area Needed | 650-1100 m² | 800 m² | 1200 m² |

| Warranty | 3 Years | 1 Year | 5 Years |

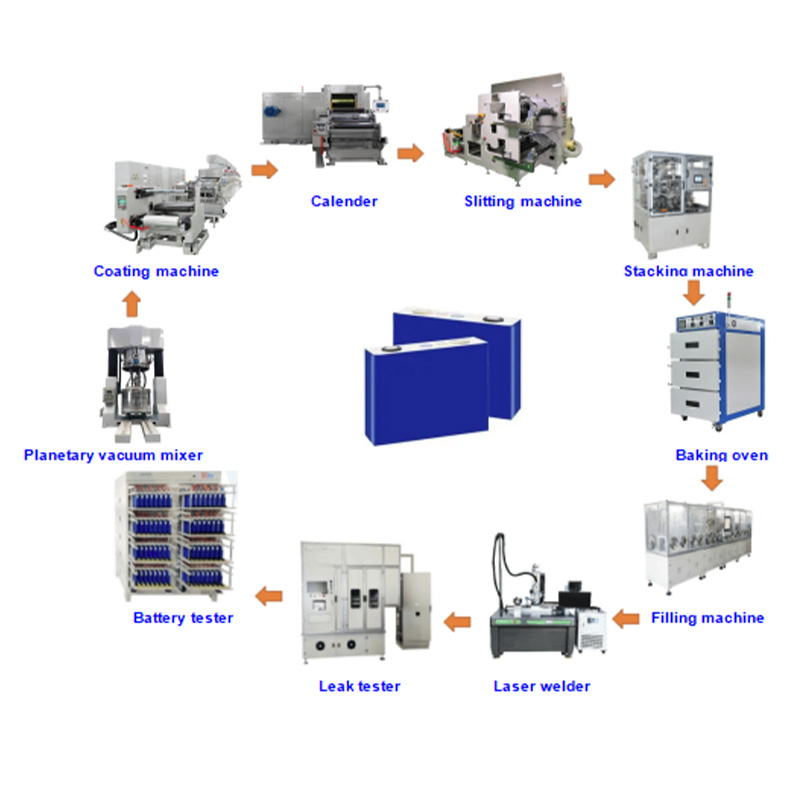

3. Detailed Process Flow of Car Battery Production Line

4. Core Technology Breakdown: Materials, Workmanship, and Standards

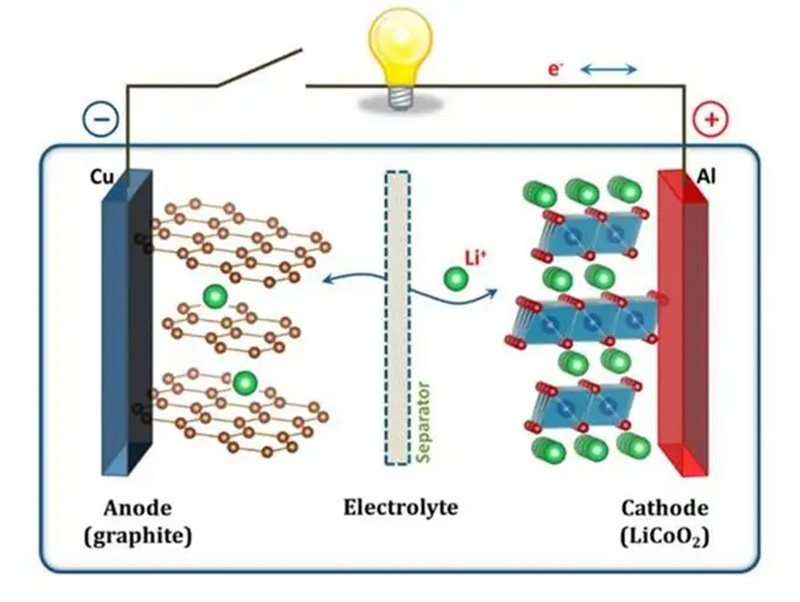

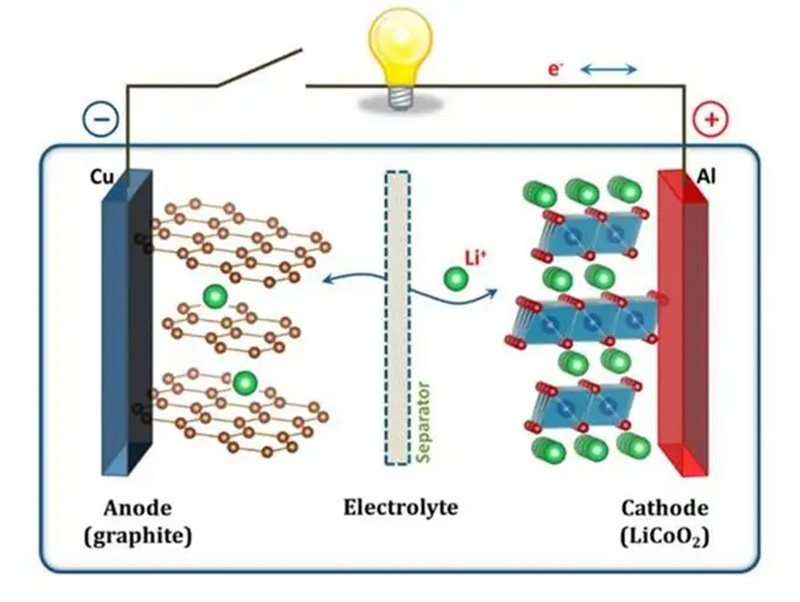

- LFP (Lithium Iron Phosphate): High temperature stability, 2000+ cycles, safe for automotive and grid.

- NMC (Nickel Manganese Cobalt): High energy density (180-220 Wh/kg), leading EV adoption.

- LTO (Lithium Titanate): Fast charging (7000 cycles, safe in harsh environments.

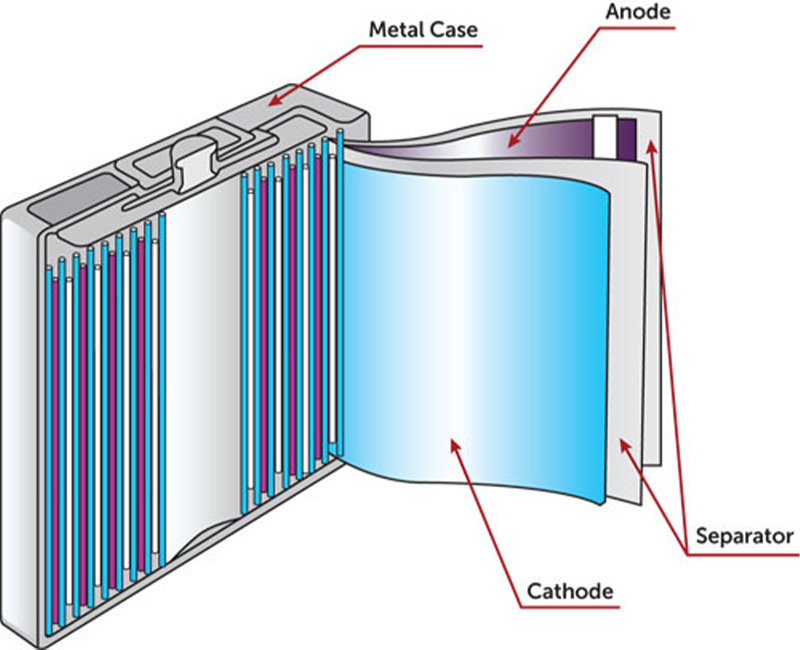

- Cast & Forged Housings: Reliable mechanical strength, superior impact resistance.

- CNC Machining: Precision cell fixtures & frames, tolerance ±0.05mm (conforms to ANSI B4.1).

- Ultrasonic & Laser Welding: Seamless tab connections, minimal resistance, ANSI/AAMI ST79 validated.

- ISO/IEC 62619: Battery safety & cycle test (thermal, overcharge, short circuit, drop).

- IEC 61427-1: Stationary applications test, grid support reliability.

- ANSI/ASQ Z1.4: Statistical QC, AQL 0.4 best-in-class defect control.

Application: Automotive (EV, Hybrid, Commercial Vehicles), Industrial ESS, Renewable Energy, Petrochemical, Metallurgy, Water Utility (car battery production line supports custom industry modules).

5. Leading Manufacturers Comparison: Car Battery Production Line Suppliers

| Manufacturer | Model/Series | Main Tech | Certifications | Strengths |

|---|---|---|---|---|

| Shuoding Intelligence | EV Car Battery LFP/NMC/LTO 30Ah-200Ah Line | CNC, Full Auto, MES, Modular Standards | ISO 9001, ISO14001, ISO/IEC 62619 |

Custom formats, robust after-sale, global export |

| Wuxi Lead | EV Power Pack G4 Series | Laser Welding, Robotic, Traceability | ISO 9001, IEC 61508 | High-speed, Industry 4.0 smart modules |

| Tesla Giga Machine | Cell/Pack 4680 Line | AI-driven, Dry Electrode, Gigascale | ISO 9001, ANSI/ESD S20.20 | Gigafactory integration, ultra-high output |

| Golden Age Tech | BAT-EVC 500A | Hybrid Automation, Multi-format | ISO 9001 | Middle-range, cost-performance lines |

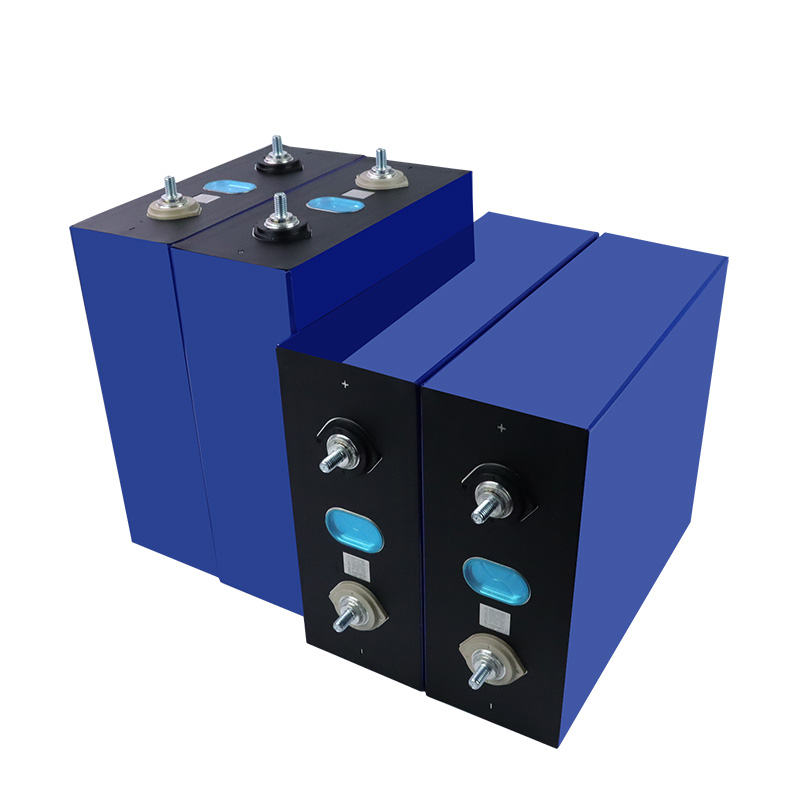

6. Custom Solution: EV Car Battery LFP/NMC/LTO 30Ah 50Ah 100Ah 200Ah Production Line

- Battery Types: Support both module and pack formats from 30Ah to 200Ah, LFP/NMC/LTO chemistries.

- Workflow Customization: Tailored for car, bus, energy storage, engineering/industrial vehicles.

- Factory Integration: MES system, ESD control, clean-room compliance,

- Safety: Arc fault, humidity, and pressure monitoring built into each section.

- Certifications: ISO 9001ISO/IEC 62619CE

- Power Consumption: ≤45 KW-h/100pcs (17% below industry average, IEA 2023).

- Remote Commissioning: Video, AR service support—global adaptivity proven in 22+ countries.

7. Application Cases & Feedback: Car Battery Production Line In Practice

- “Our cell reject rates dropped to 0.22% after switching to this EV car battery line – QC vision systems are reliable.” (SOE, India)

- “Integration with MES and remote startup by AR cut our time-to-market in half.” (EV Bus Maker, Germany)

- “Energy consumption per GWh delivered was well below promised spec, with excellent after-sale support.” (Utility ESS, USA)

8. FAQ: Professional Technical FAQ for Car Battery Production Line

Q1: What are the main material options for car battery production line components?

A1: Top-grade stainless steel (SUS304/SUS316), high-conductivity copper (C1100), and aluminum are standard for structure and tabs. Laser/ultrasonic welding is used for superior joint integrity, while specialized polymers (PBT/PEEK) are present in insulation and fixtures.

Q2: Which international standards must EV battery assembly lines comply with?

A2: Critical standards include ISO 9001/14001 (quality/environment), ISO/IEC 62619 (safety), GB/T 31484 (China), and ANSI/ASQ Z1.4 (QC). Requirements for BMS and pack integration also reference UN 38.3 for transport safety.

Q3: What is the typical delivery time and what factors may extend it?

A3: Standard delivery for the EV Car Battery LFP/NMC/LTO 30Ah 50Ah 100Ah 200Ah production line is 90-120 days. Custom automation, unique cell sizes, special certifications, or cleanroom requirements may extend this period by 2-6 weeks.

Q4: How are product warranties and after-sales support handled?

A4: All lines come with 3-year global warranty. Remote technical support is 24/7 via video/AR. Component swaps under warranty shipped in 48h; lifetime updates for MES and software systems provided for registered clients.

Q5: What is the maximum supported battery format in one line?

A5: This production line supports 30Ah, 50Ah, 100Ah, and 200Ah modules with segment changeover in <40 minutes. Custom modules up to 450Ah available on request, subject to project discussion.

Q6: How does compliance with AQL/ISO increase reliability?

A6: AQL 0.4 (ANSI/ASQ Z1.4) assures defect rate <0.4%, while full traceability, leak/impedance/short-circuit tests per ISO/IEC 62619 guarantee pack safety and lasting performance.

Q7: How is installation and overseas commissioning managed?

A7: Onsite + remote hybrid: 2-3 expert engineers dispatched for setup, user training, and safe operation. Remote AR commissioning enables pandemic-proof, cost-effective ramp-up in over 22 countries.

9. Project Implementation, Lead Time, and Service Guarantee

- Delivery/Lead Time: 90-120 days (complete turnkey delivery); optional fast-track (65-75 days) for urgent projects.

- Service/Support:

- 24h/7d global hotline & expert technical remote support

- On-site commissioning + worldwide training (multi-language)

- Spare parts logistics in 48-72h worldwide (via air express)

- Warranty: 3 years full system, extended 5-year options

- Documentation: ISO/ANSI-certified test reports, maintenance, and operation manuals included (English/Chinese/Spanish available).

10. More Industry Knowledge & Authoritative References

- IEA Global EV Outlook 2023 (iea.org)

- Battery Manufacturing Process Forum: Detailed manufacturing techniques, burning issues & line setup FAQ (batteryuniversity.com)

- Advanced Energy Materials: Peer-reviewed battery journal (Wiley)

- Statista: Lithium-Ion Battery Market Data (statista.com)

- International Battery Association: Standardization and case studies (ibainternational.org)

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025