Battery Production Equipment | Precise, Scalable, Turnkey

Battery Production Equipment is a key solution in the new energy industry industry, specifically within Manufacturing of new energy equipment and Manufacturing of specialized equipment for battery production. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Battery Production Equipment Overview

- Benefits & Use Cases of Battery Production Equipment in Manufacturing of specialized equipment for battery production

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in new energy industry

- Conclusion on Battery Production Equipment from XINGTAI SHUODING TRADING CO.,LTD

Battery Production Equipment Overview

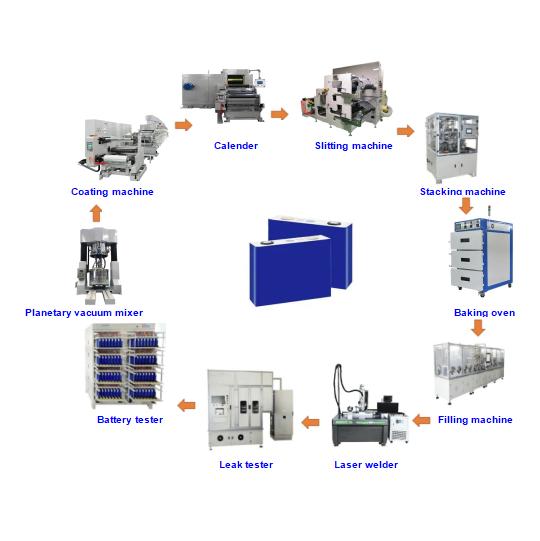

Battery Production Equipment encompasses the specialized machinery and integrated lines required to convert electrode materials into finished cells and packs at industrial scale. From slurry mixing, coating, calendaring, slitting, and stacking/winding to tab welding, vacuum drying, electrolyte filling, sealing, formation and aging, OCV/IR testing, and sorting, a modern line orchestrates hundreds of interdependent steps. In the new energy industry, precision, repeatability, and throughput determine competitiveness, making robust battery manufacturing equipment essential for lithium-ion, LFP, NMC, and emerging chemistries.

Technically, leading solutions integrate servo control, closed-loop tension management, real-time SPC, and MES connectivity for end-to-end traceability. Machine vision enables defect detection on electrodes and separators, while controlled environments reduce moisture and contamination risk. For cell finishing, battery formation equipment ensures stable SEI formation with accurate current profiles and temperature control. XINGTAI SHUODING TRADING CO.,LTD delivers complete and modular systems—battery manufacturing machine options that scale from pilot to gigafactory—backed by rigorous quality standards and application engineering to align the line with your takt-time and yield objectives.

Benefits & Use Cases of Battery Production Equipment in Manufacturing of specialized equipment for battery production

In cell and pack manufacturing, Battery Production Equipment supports critical applications across prismatic, cylindrical, and pouch formats. Coating and calendaring modules deliver consistent electrode density; precision slitting protects edge integrity; automated stacking or winding ensures layer accuracy; welding stations improve tab and busbar reliability; drying and electrolyte filling minimize moisture and gas defects; and formation-aging systems stabilize performance before grading. For B2B decision makers, the result is higher first-pass yield, tighter cell dispersion, and predictable scale-up from pilot to mass production.

- Specific applications: EV traction cells, energy storage systems, consumer electronics, and industrial backup power lines.

- Competitive advantages: modular layouts, fast recipe changeover, integrated safety interlocks, and MES-ready data for genealogy and compliance.

- Equipment portfolio: lithium battery manufacturing machines, lithium ion battery manufacturing equipment, and end-of-line battery formation equipment for reliable grading and sorting.

XINGTAI SHUODING TRADING CO.,LTD combines process know-how with robust mechanical design, delivering battery manufacturing equipment that balances throughput with quality. Their engineering teams collaborate on requirements—cell format, active material, solvent recovery, and environment class—to configure a right-sized line with future expansion in mind.

Cost, Maintenance & User Experience

For B2B buyers, total cost of ownership matters more than unit price. XINGTAI SHUODING TRADING CO.,LTD designs Battery Production Equipment with durable components, standardized spares, and accessible layouts to reduce downtime and maintenance hours. Energy-efficient drives, heat recovery on drying systems, and optimized vacuum pumps lower operating costs. Over a multi-year horizon, productivity gains and yield improvements typically outweigh initial CAPEX, strengthening ROI for EV and ESS programs where OEE and scrap rates are decisive.

- Durability: rigid frames, precision rollers, and robust winding stations extend service life and maintain alignment.

- Maintainability: clear HMI diagnostics, remote support options, and modular subassemblies streamline troubleshooting.

- User experience: intuitive recipe management reduces changeover time, while safety systems protect operators and equipment.

Feedback from manufacturers in the new energy equipment sector emphasizes stable operation across long shifts, consistent coating quality, and reliable formation data capture. Customers also value scalable configurations—expanding from pilot battery manufacturing machine cells to multi-line production without reengineering the entire plant.

Sustainability & Market Trends in new energy industry

Global demand for lithium-ion and next-generation batteries continues to rise, driven by EV adoption, grid-scale storage, and industrial electrification. In parallel, regulations increasingly require carbon footprint transparency, responsible sourcing, and recycling-readiness. Manufacturers are investing in solvent recovery for NMP, low-energy dry rooms, closed-loop cooling, and data-backed traceability to meet evolving standards and customer expectations. Battery Production Equipment that supports these goals—energy-efficient drives, advanced process control, and real-time quality analytics—helps producers stay competitive and compliant.

- Sustainability levers: solvent reclamation, heat recovery in drying ovens, material yield optimization, and end-of-line scrap reduction.

- Digitalization: MES integration for genealogy, automated reporting for audits, and predictive maintenance to extend equipment life.

Positioned as a forward-thinking partner, XINGTAI SHUODING TRADING CO.,LTD aligns equipment design with eco-conscious best practices and market trends. Whether you’re deploying a lithium battery manufacturing machine for a targeted product line or scaling a full lithium ion battery manufacturing equipment suite for a multi-GWh facility, the company’s solutions enable sustainable growth without compromising throughput or quality.

Conclusion on Battery Production Equipment from XINGTAI SHUODING TRADING CO.,LTD

Battery Production Equipment sits at the core of the new energy industry, enabling precise, efficient, and scalable manufacturing across cell and pack formats. With a portfolio that spans coating to formation, plus strong integration, safety, and traceability, XINGTAI SHUODING TRADING CO.,LTD delivers dependable battery manufacturing equipment for high-yield, cost-effective operations. From pilot lines to full-scale plants, their engineering depth and service support de-risk expansion and accelerate time-to-market. Contact us: email: sdtrading0927@126.com — Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025