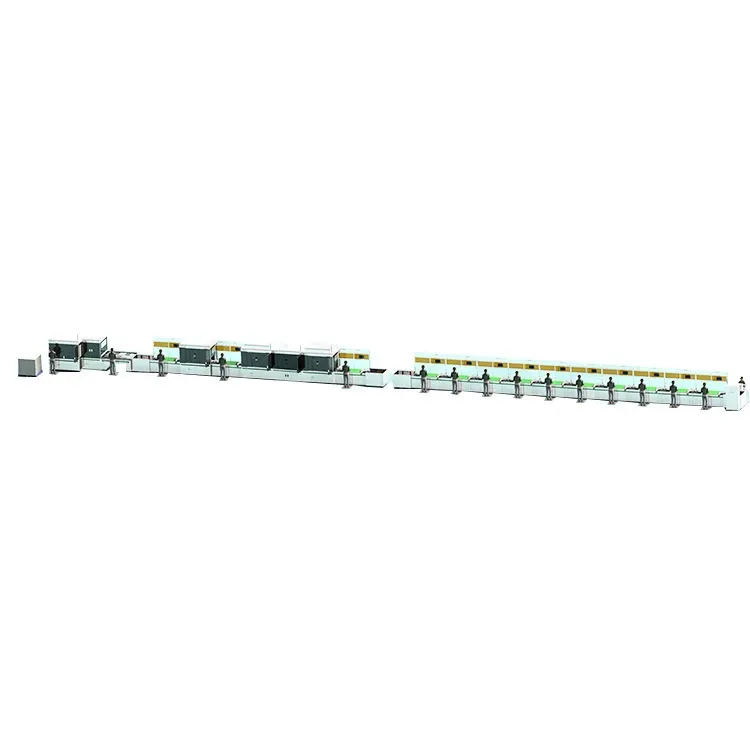

Battery Pack Automated Assembly Production Line

1: Introduction:

This production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main processes include manual feeding, OCV sorting and scanning, secondary scanning, manual insertion into brackets, AI polarity detection, NG station, A-side laser welding, automatic fixture plate flipping, B-side laser welding, and manual fixture disassembly. It features a unique double-sided cross spot welding equipment, achieving one-time welding without flipping or moving.

2: Application:

New energy vehicle battery production, portable electronic device battery production, energy storage system battery production.

3: Technical Features:

- Highly standardized, with automation modules selectable based on customer needs.

- Unique double-sided cross spot welding equipment, reducing equipment cost and simplifying operation.

- Strong device compatibility, quick and simple changeover, with one-click program implementation.

- Customizable MES modules including plan management, process roadmap management, equipment management, production reporting, etc.

4: Technical Parameters:

- Dimensions: 45.5M×3.4M×2.3M.

- Weight: 3000KG.

- Voltage: 220V.

- Power: 20000W.

- Production Capacity: ≧30PPM.

- Key Equipment: Automated assembly line for battery pack.

5: Introducing our state-of-the-art Battery Pack Automated Assembly Production Line, engineered to revolutionize the manufacturing process for battery packs with unrivaled efficiency and precision. Designed to meet the growing demand for high-quality battery solutions across various sectors—including electric vehicles, renewable energy storage, and consumer electronics—this advanced production line optimizes every phase of assembly, from individual cell integration to complete pack formation. The system integrates cutting-edge robotics and intelligent automation technologies, ensuring seamless operations that maximize throughput while maintaining stringent quality control standards. With its modular design, the production line can be customized to accommodate various battery configurations and sizes, allowing manufacturers to adapt quickly to evolving market demands. Our Battery Pack Automated Assembly Production Line boasts smart diagnostics and real-time monitoring capabilities, enabling consistent performance tracking and immediate troubleshooting to minimize downtime and enhance productivity. Safety is paramount; thus, the system incorporates advanced features that ensure operator well-being while maintaining a smooth assembly process. The user-friendly interface empowers operators to easily oversee operations, manage workflows, and implement adjustments as necessary, resulting in optimal efficiency throughout the production cycle. This innovative assembly solution not only reduces labor costs and production times but also increases the overall scalability of battery pack manufacturing operations. With its compelling blend of performance, flexibility, and reliability, our Battery Pack Automated Assembly Production Line sets a new industry standard, positioning your business to thrive in the competitive landscape of battery technology. Elevate your production capacity and quality with this transformative solution that caters to the future of energy storage and portable power applications. Invest in our Battery Pack Automated Assembly Production Line today and watch your production capabilities reach new heights.

Вести