High-Efficiency Car Battery Production Line | Automated Assembly

Pioneering the Future of Electric Vehicle Battery Manufacturing

The global automotive industry is undergoing a transformative shift towards electrification, driven by environmental mandates, technological advancements, and burgeoning consumer demand for Electric Vehicles (EVs). At the heart of this revolution lies the sophisticated process of battery manufacturing, where the efficiency, reliability, and scalability of the car battery production line dictate the pace of innovation. This intricate network of highly automated machinery and precise engineering is not merely an assembly process; it is a strategic imperative for manufacturers aiming to meet the rigorous demands of the EV market.

Industry data highlights a projected Compound Annual Growth Rate (CAGR) of over 20% for the EV battery market in the coming decade, underscoring the critical need for advanced manufacturing capabilities. Companies seeking to capitalize on this growth must invest in cutting-edge solutions for their car battery production lines, ensuring high throughput, consistent quality, and adaptability to evolving battery chemistries like LFP, NMC, and LTO. Our expertise in designing and deploying state-of-the-art battery manufacturing systems positions us as a key partner in this dynamic landscape. The advancements in automated processing and quality control within modern ev battery assembly lines are paramount to achieving cost-effectiveness and performance benchmarks in the competitive EV sector.

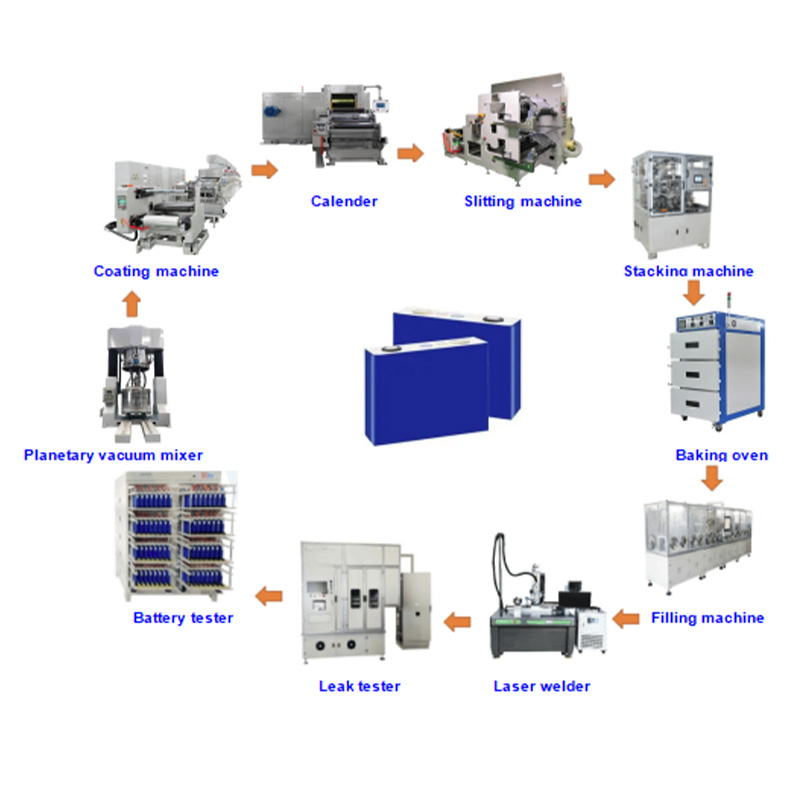

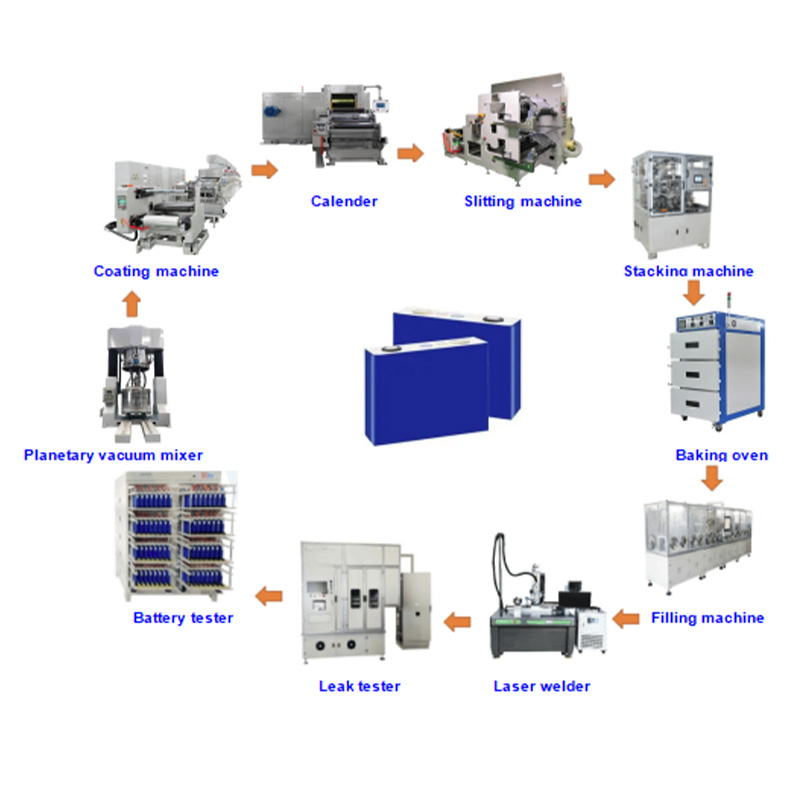

The Advanced Car Battery Production Line: A Comprehensive Process Flow

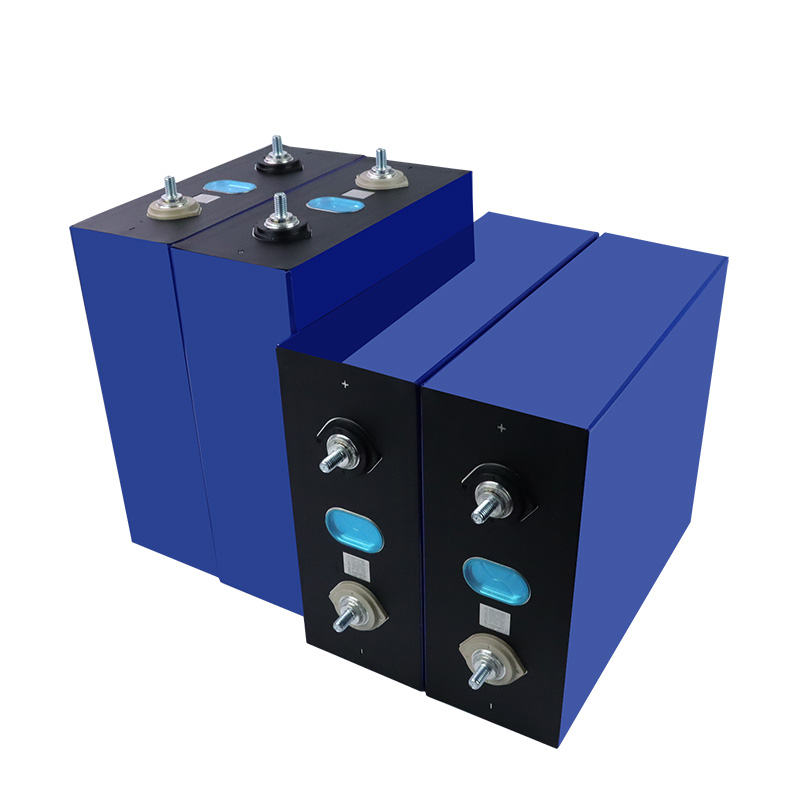

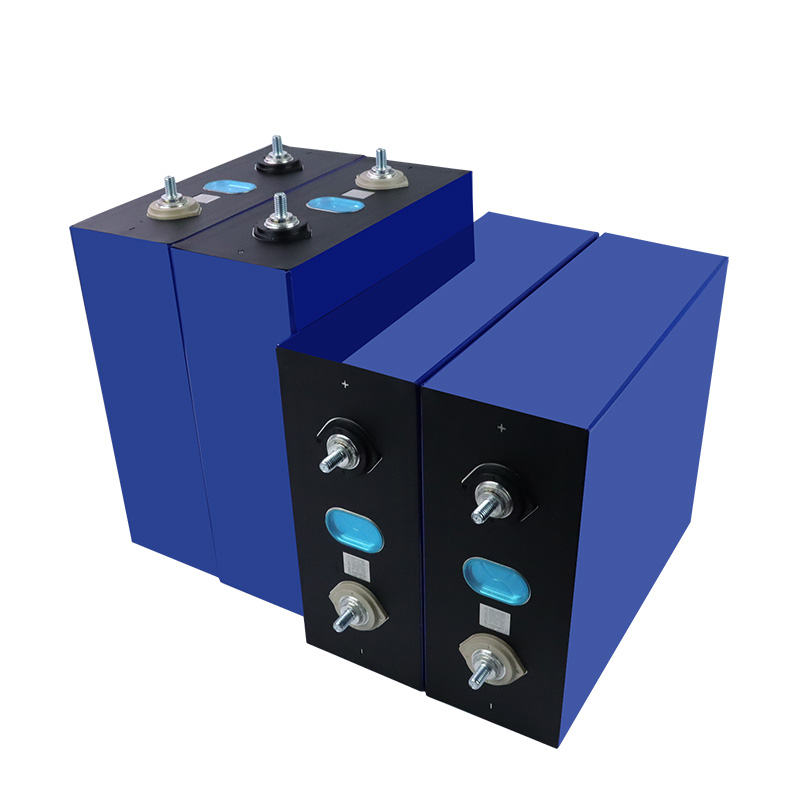

Developing high-performance EV batteries requires a meticulously engineered and rigorously controlled manufacturing process. Our car battery production line for LFP/NMC/LTO cells, ranging from 30Ah to 200Ah, integrates the latest automation and quality assurance technologies to ensure superior product quality and operational efficiency. The entire manufacturing process adheres strictly to international testing standards such as ISO 9001 for quality management and ISO 14001 for environmental management, alongside relevant ANSI/UL standards for safety.

Key Stages of Battery Manufacturing:

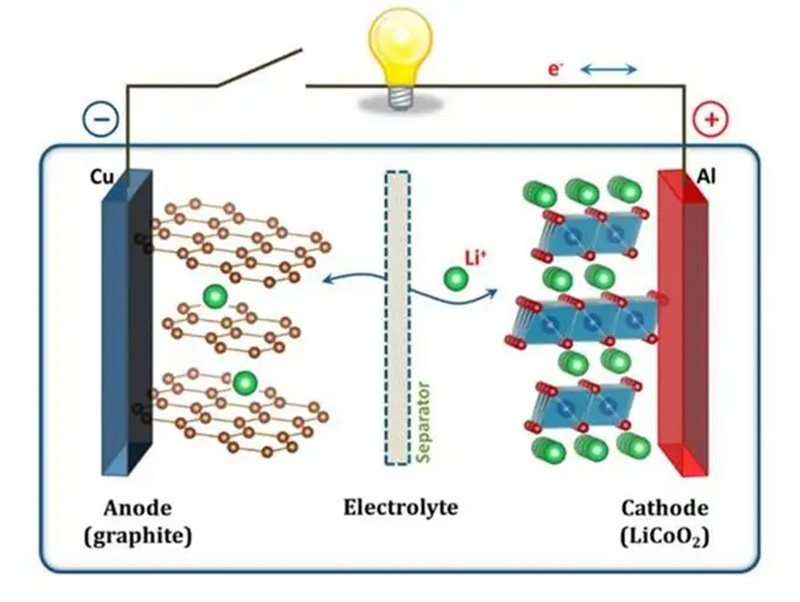

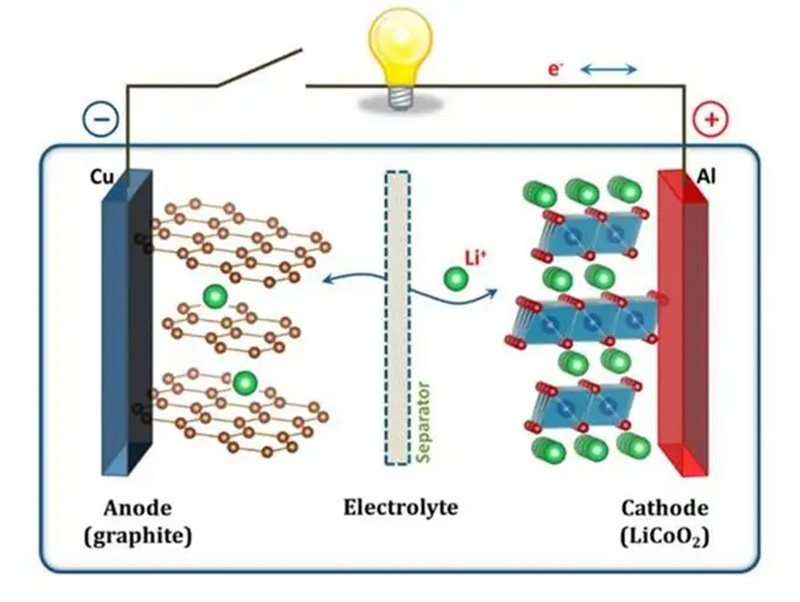

- Electrode Preparation (Mixing, Coating, Calendering): This foundational step involves precision mixing of active materials (LFP, NMC, LTO), conductive additives, and binders into a slurry. This slurry is then uniformly coated onto metal current collectors (aluminum for cathode, copper for anode) using high-precision coating machines. Following coating, the electrodes undergo calendering – a compression process that compacts the material, optimizes density, and improves electrical contact, crucial for energy density and power output. Our lines incorporate advanced gravimetric and thickness control systems to ensure uniformity, which is critical for cell performance and service life.

- Slitting and Cutting: Large coated electrode sheets are precisely slit into individual electrode strips and then cut to specified dimensions. This process demands extreme accuracy to prevent short circuits and ensure optimal cell assembly. Laser cutting and advanced slitting technologies are employed to achieve micron-level precision.

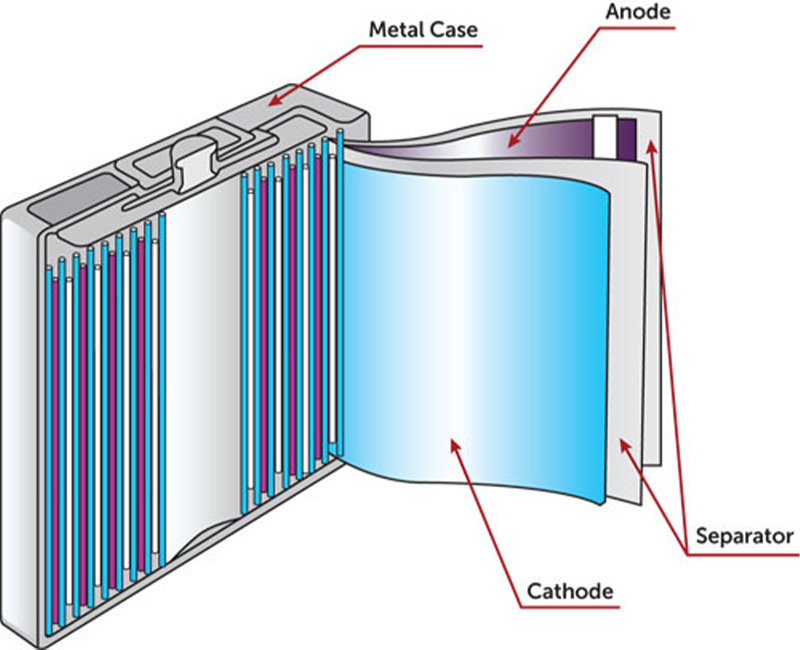

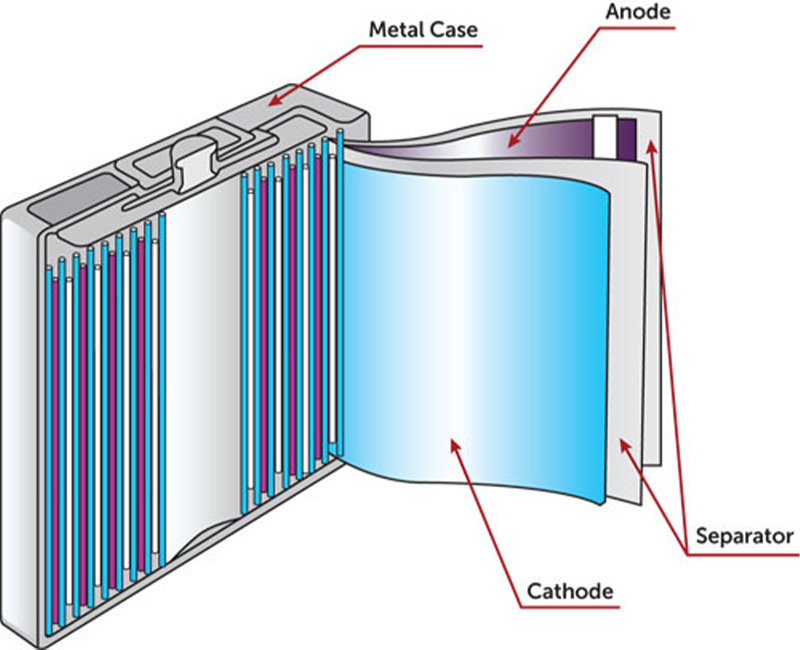

- Cell Assembly (Winding/Stacking, Welding): Depending on the cell format (cylindrical, pouch, prismatic), electrodes and separators are either wound into jelly rolls or stacked alternately. Automated winding/stacking machines ensure tight tolerances. Tabs are then welded to the current collectors using ultrasonic or laser welding, creating robust electrical connections. This entire sequence is performed in highly controlled dry room environments to prevent moisture contamination.

- Electrolyte Filling and Sealing: The assembled cell is carefully filled with electrolyte under vacuum conditions to ensure complete saturation of the porous electrode structure. This is a critical step for ionic conductivity. After filling, the cell is hermetically sealed to prevent electrolyte leakage and moisture ingress, maintaining the integrity and long service life of the battery.

- Formation and Aging: During formation, the battery undergoes initial charge/discharge cycles to activate the active materials and form the Solid Electrolyte Interphase (SEI) layer on the anode. This layer is crucial for battery performance and longevity. Subsequently, cells are aged (rested) at controlled temperatures to allow for stabilization and to detect any latent defects before final testing.

- Sorting and Packaging: Cells are meticulously tested for voltage, internal resistance, capacity, and self-discharge rate. Based on these parameters, cells are sorted into specific grades to ensure uniformity within battery packs, optimizing overall pack performance and safety. Finally, cells are prepared for module and pack assembly or direct shipment.

The materials utilized in our production lines are sourced from verified suppliers, adhering to stringent quality control, minimizing impurities and maximizing battery performance. For instance, high-purity lithium sources, carbon black for conductivity, and PVDF/SBR binders are selected to ensure optimal electrochemical properties and structural integrity, contributing to a longer service life (typically >3000 cycles for LFP cells to 80% DoD).

Technical Specifications of Our EV Car Battery Production Line

Our comprehensive EV car battery production line is designed for versatility and high performance, capable of manufacturing a wide range of battery cell types and capacities. This system caters to the evolving demands of the electric vehicle market and stationary energy storage solutions.

Product Specification Table: EV Car Battery LFP/NMC/LTO Production Line

Each module within our ev battery assembly line is engineered for seamless integration, ensuring a streamlined and highly efficient manufacturing flow. The modular design also allows for future upgrades and expansion, safeguarding your investment.

Broad Spectrum Application of Our EV Battery Assembly Lines

Our advanced battery production solutions are not limited to a single application but are designed to empower manufacturers across diverse high-growth sectors. The flexibility of our EV car battery production line allows for tailored outputs that meet specific industry requirements, from high-power cells for performance EVs to long-cycle cells for grid-scale energy storage.

Primary Target Industries:

- Automotive (Electric Vehicles & Hybrid Vehicles): This is the core application, encompassing passenger EVs, commercial electric vehicles (buses, trucks), and hybrid electric vehicles (HEVs/PHEVs). Our lines produce high-energy density cells (NMC) for long-range, high-performance vehicles and robust, safe cells (LFP) for urban mobility and commercial fleets.

- Energy Storage Systems (ESS): Grid-scale battery storage, residential energy storage, and industrial backup power systems rely heavily on high-capacity, long-life LFP cells. Our production lines are optimized for cost-effective, high-volume manufacturing of these critical components, facilitating grid stabilization and renewable energy integration.

- Industrial & Specialty Applications: This includes batteries for electric forklifts, Automated Guided Vehicles (AGVs), marine applications, and specialized industrial machinery. LTO battery production, for instance, is ideal for applications requiring extremely fast charging, high power, and exceptional cycle life, even in harsh conditions.

- Consumer Electronics (High-End): While not the primary focus, the technology can be adapted for larger format cells used in high-power consumer electronics and portable energy solutions, demanding precision and reliability.

Advantages in Typical Application Scenarios:

For EV manufacturers, our lines deliver cells with exceptional energy density, enabling longer driving ranges (e.g., NMC cells achieving over 500 Wh/L volumetric energy density). For ESS providers, the emphasis is on safety and cycle life, with LFP cells from our lines demonstrating >6,000 cycles to 70% DoD, providing excellent return on investment. The advanced automation ensures consistent quality, leading to reduced warranty claims and enhanced brand reputation.

Unparalleled Technical Advantages of Our Car Battery Production Line

Our commitment to innovation and engineering excellence translates into significant technical advantages for clients investing in our car battery production line solutions. These differentiators are critical for achieving competitive advantage in the rapidly evolving battery market.

Core Advantages:

- Superior Automation & Precision: Our lines feature advanced robotics, AI-driven vision systems, and closed-loop control for all critical processes, from slurry mixing to electrode winding and laser welding. This ensures micron-level precision, minimizing defects and maximizing cell consistency, which directly impacts battery pack performance and safety.

- Flexibility for Multi-Chemistry Production: Designed with modularity in mind, our lines can seamlessly switch between LFP, NMC, and LTO chemistries with minimal downtime. This adaptability is crucial for manufacturers serving diverse markets and responding to rapid material science innovations.

- Enhanced Energy Efficiency: Incorporating advanced heat recovery systems in drying ovens, optimized motor drives, and smart energy management throughout the plant significantly reduces operational energy consumption. This translates to lower manufacturing costs and a reduced carbon footprint, addressing both economic and environmental concerns.

- Robust Quality Control & Traceability: Every cell produced is subjected to comprehensive inline and offline quality checks, including electrochemical impedance spectroscopy (EIS), X-ray inspection for internal defects, and precise capacity testing. A full data traceability system links each cell to its production parameters, enabling rapid fault identification and continuous process improvement, crucial for authoritative performance validation (e.g., UN 38.3).

- Scalability & Future-Proofing: Our solutions are built to scale, allowing clients to expand capacity from initial GWh levels to multi-GWh outputs. The integration of Industry 4.0 principles, including IoT sensors, predictive maintenance, and real-time data analytics, ensures the production line remains cutting-edge and adaptable to future technological shifts.

These advantages collectively lead to higher yields, reduced operational expenditures (OpEx), faster time-to-market for new battery products, and ultimately, a more competitive position in the global battery landscape.

Vendor Comparison: Why Choose Our Car Battery Production Line

In a market with various equipment suppliers, discerning the optimal partner for a critical investment like an EV battery assembly line requires careful consideration of capabilities, support, and long-term value. Our commitment to expertise, experience, and trustworthiness sets us apart.

Comparative Advantages:

Our reputation is built on decades of experience in high-precision manufacturing and automation. We partner with industry leaders and hold numerous certifications, demonstrating our commitment to quality and safety. Our client roster includes several top-tier automotive OEMs and energy solution providers globally, a testament to our authoritative standing in the industry.

Tailored Excellence: Customized Car Battery Production Line Solutions

Recognizing that every manufacturer has unique requirements, space constraints, and production targets, we specialize in providing highly customized ev battery assembly line solutions. Our engineering team works closely with clients from conceptualization to commissioning, ensuring the final system perfectly aligns with their strategic objectives.

- Capacity Scaling: Whether you require a pilot line for R&D or a multi-gigawatt-hour factory, our solutions are designed to scale. We can configure systems for specific annual production capacities (e.g., from 1 GWh to 20 GWh and beyond).

- Cell Form Factor & Chemistry Adaptability: Our lines are adaptable to various cell formats (prismatic, pouch, cylindrical) and chemistries (LFP, NMC, LTO), allowing for quick retooling and flexibility in product offerings.

- Facility Integration: We provide comprehensive layout design, utility integration, and cleanroom/dryroom solutions to ensure seamless fit within existing or new manufacturing facilities.

- Advanced Process Module Integration: Clients can opt for advanced modules such as high-speed laser welders, sophisticated inline metrology for quality control, or specific post-processing equipment (e.g., degassing, pre-charging) to enhance performance or meet niche market demands.

Our consultative approach ensures that every aspect of the project, from initial design specifications to final validation, is managed with precision and transparency, delivering a solution that maximizes your operational return on investment.

Real-World Impact: Application Case Studies & Client Success

Our dedication to delivering high-performance car battery production lines has resulted in numerous successful deployments globally. These case studies highlight the tangible benefits our clients have realized.

Case Study 1: Scaling EV Battery Production for a Leading OEM

A major global automotive OEM partnered with us to establish a new 5 GWh/year NMC battery production facility. Our solution integrated high-speed coating and calendering modules, followed by a fully automated cell assembly and formation line.

- Challenge: Rapidly scale production to meet increasing EV demand while maintaining stringent quality control for high-energy density cells.

- Solution: Deployed a turnkey EV battery assembly line with integrated MES (Manufacturing Execution System) for real-time data monitoring and process optimization.

- Result: Achieved target production capacity within 18 months, with a sustained yield rate of 98.5% and a 15% reduction in energy consumption compared to initial projections, significantly lowering OpEx.

Case Study 2: Developing a Flexible LFP Line for Stationary Storage

An emerging energy storage solution provider required a production line capable of manufacturing various LFP cell sizes (100Ah, 200Ah) for their modular ESS products.

- Challenge: Need for high flexibility in cell format and capacity on a single line, coupled with robust cycle life requirements for grid applications.

- Solution: Engineered a modular car battery production line with quick-change tooling and recipe management systems, enabling rapid transitions between different cell specifications.

- Result: Enabled production of multiple LFP cell variants with minimal retooling time, achieving consistent cell-to-cell uniformity essential for long-lasting ESS applications. Customer feedback highlighted the exceptional flexibility and the immediate positive impact on their market responsiveness.

Building Trust: FAQs, Lead Times, Warranty, and Support

Transparency and robust support are pillars of our commitment to client success. We aim to provide clear information on all aspects of our partnership.

Frequently Asked Questions (FAQs):

Q: What is the typical lead time for a complete car battery production line?

A: Lead times vary based on the complexity and scale of the line. For a standard 1-2 GWh line, it typically ranges from 12 to 24 months, including design, manufacturing, installation, and commissioning. Custom lines may require additional time for engineering.

Q: Can your production line handle both LFP and NMC battery types?

A: Yes, our production lines are designed with inherent flexibility to process LFP, NMC, and LTO chemistries. Depending on the level of customization, quick changeover capabilities can be integrated to minimize downtime when switching between chemistries.

Q: What kind of after-sales support do you offer?

A: We offer comprehensive global after-sales support, including 24/7 technical assistance, remote diagnostics, on-site maintenance and repair services, spare parts management, and continuous process optimization consultation. Our dedicated teams ensure your production remains operational and efficient.

Lead Time & Fulfillment:

Our project management methodology emphasizes transparent communication and adherence to agreed-upon timelines. We utilize advanced planning tools to manage complex supply chains and manufacturing schedules, ensuring timely delivery and installation of your ev battery assembly line. A detailed project plan with clear milestones and regular progress reports is provided to every client.

Warranty Commitments:

We stand by the quality and performance of our equipment. All core components of our production lines come with a standard 1-year warranty, with extended warranty options available. This covers manufacturing defects and ensures component integrity. Specific performance guarantees, such as yield rates and precision tolerances, are often included in project contracts, underscoring our confidence in our technology.

Customer Support & Training:

Beyond maintenance, we provide extensive training programs for your operational and technical staff. This includes on-site training during commissioning, detailed operational manuals, and ongoing remote support webinars. Our goal is to empower your team to operate and troubleshoot the car battery production line independently and efficiently, ensuring long-term operational success.

Conclusion: Powering the Electric Future

The demand for efficient, reliable, and high-performance EV batteries continues to escalate, making the choice of an advanced car battery production line a pivotal strategic decision for any manufacturer. Our solutions offer unparalleled precision, flexibility across multiple battery chemistries (LFP, NMC, LTO), and robust automation, backed by comprehensive support and a proven track record of client success. By partnering with us, you invest in a future-proof manufacturing capability that delivers superior cell quality, optimized operational efficiency, and a significant competitive advantage in the global electrification movement.

We are dedicated to being your trusted partner in navigating the complexities of advanced battery manufacturing, providing not just equipment, but a complete ecosystem of technology, expertise, and support to power the next generation of electric vehicles and energy storage solutions.

References:

- International Energy Agency (IEA) – Global EV Outlook reports. Retrieved from IEA.org.

- BloombergNEF – Electric Vehicle Outlook, various years. Retrieved from BNEF.com.

- Journal of Power Sources – Peer-reviewed articles on advanced battery manufacturing and materials.

- Electrochemical Society (ECS) Publications – Research on battery electrochemistry and production techniques.

- ISO (International Organization for Standardization) – Standards for Quality Management (ISO 9001) and Environmental Management (ISO 14001). Retrieved from ISO.org.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025

High-Efficiency Car Battery Production Line | Automated Assembly

Pioneering the Future of Electric Vehicle Battery Manufacturing

The global automotive industry is undergoing a transformative shift towards electrification, driven by environmental mandates, technological advancements, and burgeoning consumer demand for Electric Vehicles (EVs). At the heart of this revolution lies the sophisticated process of battery manufacturing, where the efficiency, reliability, and scalability of the car battery production line dictate the pace of innovation. This intricate network of highly automated machinery and precise engineering is not merely an assembly process; it is a strategic imperative for manufacturers aiming to meet the rigorous demands of the EV market.

Industry data highlights a projected Compound Annual Growth Rate (CAGR) of over 20% for the EV battery market in the coming decade, underscoring the critical need for advanced manufacturing capabilities. Companies seeking to capitalize on this growth must invest in cutting-edge solutions for their car battery production lines, ensuring high throughput, consistent quality, and adaptability to evolving battery chemistries like LFP, NMC, and LTO. Our expertise in designing and deploying state-of-the-art battery manufacturing systems positions us as a key partner in this dynamic landscape. The advancements in automated processing and quality control within modern ev battery assembly lines are paramount to achieving cost-effectiveness and performance benchmarks in the competitive EV sector.

The Advanced Car Battery Production Line: A Comprehensive Process Flow

Developing high-performance EV batteries requires a meticulously engineered and rigorously controlled manufacturing process. Our car battery production line for LFP/NMC/LTO cells, ranging from 30Ah to 200Ah, integrates the latest automation and quality assurance technologies to ensure superior product quality and operational efficiency. The entire manufacturing process adheres strictly to international testing standards such as ISO 9001 for quality management and ISO 14001 for environmental management, alongside relevant ANSI/UL standards for safety.

Key Stages of Battery Manufacturing:

- Electrode Preparation (Mixing, Coating, Calendering): This foundational step involves precision mixing of active materials (LFP, NMC, LTO), conductive additives, and binders into a slurry. This slurry is then uniformly coated onto metal current collectors (aluminum for cathode, copper for anode) using high-precision coating machines. Following coating, the electrodes undergo calendering – a compression process that compacts the material, optimizes density, and improves electrical contact, crucial for energy density and power output. Our lines incorporate advanced gravimetric and thickness control systems to ensure uniformity, which is critical for cell performance and service life.

- Slitting and Cutting: Large coated electrode sheets are precisely slit into individual electrode strips and then cut to specified dimensions. This process demands extreme accuracy to prevent short circuits and ensure optimal cell assembly. Laser cutting and advanced slitting technologies are employed to achieve micron-level precision.

- Cell Assembly (Winding/Stacking, Welding): Depending on the cell format (cylindrical, pouch, prismatic), electrodes and separators are either wound into jelly rolls or stacked alternately. Automated winding/stacking machines ensure tight tolerances. Tabs are then welded to the current collectors using ultrasonic or laser welding, creating robust electrical connections. This entire sequence is performed in highly controlled dry room environments to prevent moisture contamination.

- Electrolyte Filling and Sealing: The assembled cell is carefully filled with electrolyte under vacuum conditions to ensure complete saturation of the porous electrode structure. This is a critical step for ionic conductivity. After filling, the cell is hermetically sealed to prevent electrolyte leakage and moisture ingress, maintaining the integrity and long service life of the battery.

- Formation and Aging: During formation, the battery undergoes initial charge/discharge cycles to activate the active materials and form the Solid Electrolyte Interphase (SEI) layer on the anode. This layer is crucial for battery performance and longevity. Subsequently, cells are aged (rested) at controlled temperatures to allow for stabilization and to detect any latent defects before final testing.

- Sorting and Packaging: Cells are meticulously tested for voltage, internal resistance, capacity, and self-discharge rate. Based on these parameters, cells are sorted into specific grades to ensure uniformity within battery packs, optimizing overall pack performance and safety. Finally, cells are prepared for module and pack assembly or direct shipment.

The materials utilized in our production lines are sourced from verified suppliers, adhering to stringent quality control, minimizing impurities and maximizing battery performance. For instance, high-purity lithium sources, carbon black for conductivity, and PVDF/SBR binders are selected to ensure optimal electrochemical properties and structural integrity, contributing to a longer service life (typically >3000 cycles for LFP cells to 80% DoD).

Technical Specifications of Our EV Car Battery Production Line

Our comprehensive EV car battery production line is designed for versatility and high performance, capable of manufacturing a wide range of battery cell types and capacities. This system caters to the evolving demands of the electric vehicle market and stationary energy storage solutions.

Product Specification Table: EV Car Battery LFP/NMC/LTO Production Line

Each module within our ev battery assembly line is engineered for seamless integration, ensuring a streamlined and highly efficient manufacturing flow. The modular design also allows for future upgrades and expansion, safeguarding your investment.

Broad Spectrum Application of Our EV Battery Assembly Lines

Our advanced battery production solutions are not limited to a single application but are designed to empower manufacturers across diverse high-growth sectors. The flexibility of our EV car battery production line allows for tailored outputs that meet specific industry requirements, from high-power cells for performance EVs to long-cycle cells for grid-scale energy storage.

Primary Target Industries:

- Automotive (Electric Vehicles & Hybrid Vehicles): This is the core application, encompassing passenger EVs, commercial electric vehicles (buses, trucks), and hybrid electric vehicles (HEVs/PHEVs). Our lines produce high-energy density cells (NMC) for long-range, high-performance vehicles and robust, safe cells (LFP) for urban mobility and commercial fleets.

- Energy Storage Systems (ESS): Grid-scale battery storage, residential energy storage, and industrial backup power systems rely heavily on high-capacity, long-life LFP cells. Our production lines are optimized for cost-effective, high-volume manufacturing of these critical components, facilitating grid stabilization and renewable energy integration.

- Industrial & Specialty Applications: This includes batteries for electric forklifts, Automated Guided Vehicles (AGVs), marine applications, and specialized industrial machinery. LTO battery production, for instance, is ideal for applications requiring extremely fast charging, high power, and exceptional cycle life, even in harsh conditions.

- Consumer Electronics (High-End): While not the primary focus, the technology can be adapted for larger format cells used in high-power consumer electronics and portable energy solutions, demanding precision and reliability.

Advantages in Typical Application Scenarios:

For EV manufacturers, our lines deliver cells with exceptional energy density, enabling longer driving ranges (e.g., NMC cells achieving over 500 Wh/L volumetric energy density). For ESS providers, the emphasis is on safety and cycle life, with LFP cells from our lines demonstrating >6,000 cycles to 70% DoD, providing excellent return on investment. The advanced automation ensures consistent quality, leading to reduced warranty claims and enhanced brand reputation.

Unparalleled Technical Advantages of Our Car Battery Production Line

Our commitment to innovation and engineering excellence translates into significant technical advantages for clients investing in our car battery production line solutions. These differentiators are critical for achieving competitive advantage in the rapidly evolving battery market.

Core Advantages:

- Superior Automation & Precision: Our lines feature advanced robotics, AI-driven vision systems, and closed-loop control for all critical processes, from slurry mixing to electrode winding and laser welding. This ensures micron-level precision, minimizing defects and maximizing cell consistency, which directly impacts battery pack performance and safety.

- Flexibility for Multi-Chemistry Production: Designed with modularity in mind, our lines can seamlessly switch between LFP, NMC, and LTO chemistries with minimal downtime. This adaptability is crucial for manufacturers serving diverse markets and responding to rapid material science innovations.

- Enhanced Energy Efficiency: Incorporating advanced heat recovery systems in drying ovens, optimized motor drives, and smart energy management throughout the plant significantly reduces operational energy consumption. This translates to lower manufacturing costs and a reduced carbon footprint, addressing both economic and environmental concerns.

- Robust Quality Control & Traceability: Every cell produced is subjected to comprehensive inline and offline quality checks, including electrochemical impedance spectroscopy (EIS), X-ray inspection for internal defects, and precise capacity testing. A full data traceability system links each cell to its production parameters, enabling rapid fault identification and continuous process improvement, crucial for authoritative performance validation (e.g., UN 38.3).

- Scalability & Future-Proofing: Our solutions are built to scale, allowing clients to expand capacity from initial GWh levels to multi-GWh outputs. The integration of Industry 4.0 principles, including IoT sensors, predictive maintenance, and real-time data analytics, ensures the production line remains cutting-edge and adaptable to future technological shifts.

These advantages collectively lead to higher yields, reduced operational expenditures (OpEx), faster time-to-market for new battery products, and ultimately, a more competitive position in the global battery landscape.

Vendor Comparison: Why Choose Our Car Battery Production Line

In a market with various equipment suppliers, discerning the optimal partner for a critical investment like an EV battery assembly line requires careful consideration of capabilities, support, and long-term value. Our commitment to expertise, experience, and trustworthiness sets us apart.

Comparative Advantages:

Our reputation is built on decades of experience in high-precision manufacturing and automation. We partner with industry leaders and hold numerous certifications, demonstrating our commitment to quality and safety. Our client roster includes several top-tier automotive OEMs and energy solution providers globally, a testament to our authoritative standing in the industry.

Tailored Excellence: Customized Car Battery Production Line Solutions

Recognizing that every manufacturer has unique requirements, space constraints, and production targets, we specialize in providing highly customized ev battery assembly line solutions. Our engineering team works closely with clients from conceptualization to commissioning, ensuring the final system perfectly aligns with their strategic objectives.

- Capacity Scaling: Whether you require a pilot line for R&D or a multi-gigawatt-hour factory, our solutions are designed to scale. We can configure systems for specific annual production capacities (e.g., from 1 GWh to 20 GWh and beyond).

- Cell Form Factor & Chemistry Adaptability: Our lines are adaptable to various cell formats (prismatic, pouch, cylindrical) and chemistries (LFP, NMC, LTO), allowing for quick retooling and flexibility in product offerings.

- Facility Integration: We provide comprehensive layout design, utility integration, and cleanroom/dryroom solutions to ensure seamless fit within existing or new manufacturing facilities.

- Advanced Process Module Integration: Clients can opt for advanced modules such as high-speed laser welders, sophisticated inline metrology for quality control, or specific post-processing equipment (e.g., degassing, pre-charging) to enhance performance or meet niche market demands.

Our consultative approach ensures that every aspect of the project, from initial design specifications to final validation, is managed with precision and transparency, delivering a solution that maximizes your operational return on investment.

Real-World Impact: Application Case Studies & Client Success

Our dedication to delivering high-performance car battery production lines has resulted in numerous successful deployments globally. These case studies highlight the tangible benefits our clients have realized.

Case Study 1: Scaling EV Battery Production for a Leading OEM

A major global automotive OEM partnered with us to establish a new 5 GWh/year NMC battery production facility. Our solution integrated high-speed coating and calendering modules, followed by a fully automated cell assembly and formation line.

- Challenge: Rapidly scale production to meet increasing EV demand while maintaining stringent quality control for high-energy density cells.

- Solution: Deployed a turnkey EV battery assembly line with integrated MES (Manufacturing Execution System) for real-time data monitoring and process optimization.

- Result: Achieved target production capacity within 18 months, with a sustained yield rate of 98.5% and a 15% reduction in energy consumption compared to initial projections, significantly lowering OpEx.

Case Study 2: Developing a Flexible LFP Line for Stationary Storage

An emerging energy storage solution provider required a production line capable of manufacturing various LFP cell sizes (100Ah, 200Ah) for their modular ESS products.

- Challenge: Need for high flexibility in cell format and capacity on a single line, coupled with robust cycle life requirements for grid applications.

- Solution: Engineered a modular car battery production line with quick-change tooling and recipe management systems, enabling rapid transitions between different cell specifications.

- Result: Enabled production of multiple LFP cell variants with minimal retooling time, achieving consistent cell-to-cell uniformity essential for long-lasting ESS applications. Customer feedback highlighted the exceptional flexibility and the immediate positive impact on their market responsiveness.

Building Trust: FAQs, Lead Times, Warranty, and Support

Transparency and robust support are pillars of our commitment to client success. We aim to provide clear information on all aspects of our partnership.

Frequently Asked Questions (FAQs):

Q: What is the typical lead time for a complete car battery production line?

A: Lead times vary based on the complexity and scale of the line. For a standard 1-2 GWh line, it typically ranges from 12 to 24 months, including design, manufacturing, installation, and commissioning. Custom lines may require additional time for engineering.

Q: Can your production line handle both LFP and NMC battery types?

A: Yes, our production lines are designed with inherent flexibility to process LFP, NMC, and LTO chemistries. Depending on the level of customization, quick changeover capabilities can be integrated to minimize downtime when switching between chemistries.

Q: What kind of after-sales support do you offer?

A: We offer comprehensive global after-sales support, including 24/7 technical assistance, remote diagnostics, on-site maintenance and repair services, spare parts management, and continuous process optimization consultation. Our dedicated teams ensure your production remains operational and efficient.

Lead Time & Fulfillment:

Our project management methodology emphasizes transparent communication and adherence to agreed-upon timelines. We utilize advanced planning tools to manage complex supply chains and manufacturing schedules, ensuring timely delivery and installation of your ev battery assembly line. A detailed project plan with clear milestones and regular progress reports is provided to every client.

Warranty Commitments:

We stand by the quality and performance of our equipment. All core components of our production lines come with a standard 1-year warranty, with extended warranty options available. This covers manufacturing defects and ensures component integrity. Specific performance guarantees, such as yield rates and precision tolerances, are often included in project contracts, underscoring our confidence in our technology.

Customer Support & Training:

Beyond maintenance, we provide extensive training programs for your operational and technical staff. This includes on-site training during commissioning, detailed operational manuals, and ongoing remote support webinars. Our goal is to empower your team to operate and troubleshoot the car battery production line independently and efficiently, ensuring long-term operational success.

Conclusion: Powering the Electric Future

The demand for efficient, reliable, and high-performance EV batteries continues to escalate, making the choice of an advanced car battery production line a pivotal strategic decision for any manufacturer. Our solutions offer unparalleled precision, flexibility across multiple battery chemistries (LFP, NMC, LTO), and robust automation, backed by comprehensive support and a proven track record of client success. By partnering with us, you invest in a future-proof manufacturing capability that delivers superior cell quality, optimized operational efficiency, and a significant competitive advantage in the global electrification movement.

We are dedicated to being your trusted partner in navigating the complexities of advanced battery manufacturing, providing not just equipment, but a complete ecosystem of technology, expertise, and support to power the next generation of electric vehicles and energy storage solutions.

References:

- International Energy Agency (IEA) – Global EV Outlook reports. Retrieved from IEA.org.

- BloombergNEF – Electric Vehicle Outlook, various years. Retrieved from BNEF.com.

- Journal of Power Sources – Peer-reviewed articles on advanced battery manufacturing and materials.

- Electrochemical Society (ECS) Publications – Research on battery electrochemistry and production techniques.

- ISO (International Organization for Standardization) – Standards for Quality Management (ISO 9001) and Environmental Management (ISO 14001). Retrieved from ISO.org.

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025