Need Battery Production Equipment to Boost Yield & Quality?

battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment is a key solution in the new energy industry industry, specifically within Manufacturing of new energy equipment and Manufacturing of specialized equipment for battery production. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment Overview

- Benefits & Use Cases of battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment in Manufacturing of specialized equipment for battery production

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in new energy industry

- Conclusion on battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment from XINGTAI SHUODING TRADING CO.,LTD

battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment Overview

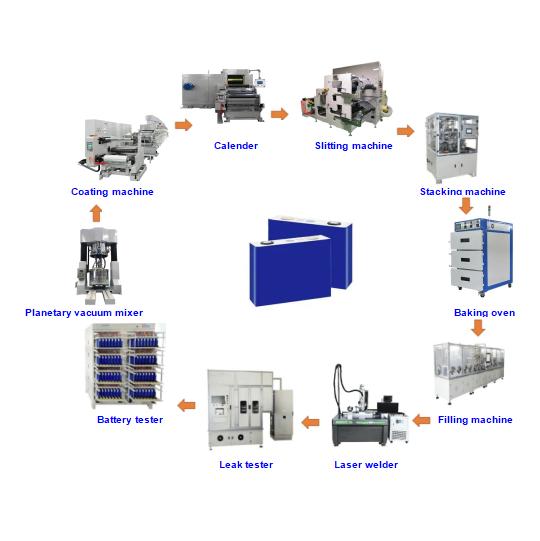

In the fast-growing e-mobility and energy storage markets, end-to-end battery production equipment is mission-critical for quality, throughput, and traceability. The category spans electrode mixing, coating and drying, calendering and slitting, cell assembly (stacking/winding, tab welding), electrolyte filling and sealing, to battery formation equipment, aging racks, and EOL testing. A modern lithium ion battery manufacturing equipment suite integrates motion control, precision vision, laser welding, and MES connectivity to ensure high yields, stable cycle times, and comprehensive genealogy.

XINGTAI SHUODING TRADING CO.,LTD provides configurable battery manufacturing equipment engineered for cylindrical, prismatic, and pouch formats. Typical specifications include micron-level coating uniformity options, precise stacking alignment, vacuum electrolyte filling, and formation/aging cabinets with programmable profiles and data logging. For example, a lithium battery manufacturing machine line can be built as modules—electrode line, assembly line, and formation/testing—allowing phased capex deployment and faster commissioning. Robust mechanical frames, industrial-grade components, and smart interlocks help deliver repeatability and safety across shifts.

Benefits & Use Cases of battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment in Manufacturing of specialized equipment for battery production

Within Manufacturing of specialized equipment for battery production, XINGTAI SHUODING TRADING CO.,LTD focuses on precision, scalability, and digitalization. Use cases range from automotive-grade EV cells to high-cycle-life ESS modules and compact consumer cells. The lithium battery manufacturing machine portfolio supports electrode mix-to-cell workflows, enabling consistent slurry processing, stable coating/drying, accurate calendering, and burr-free slitting that feed high-yield stacking or winding cells. Downstream, the lithium ion battery manufacturing equipment integrates laser or ultrasonic welding, electrolyte metering, and hermetic sealing to protect cell integrity.

Competitive advantages include modular conveyor logistics, in-line vision for defect detection, recipe management for quick format changeovers, and seamless MES/SCADA integration for traceability and OEE monitoring. Battery formation equipment with flexible current profiles, temperature management, and safety diagnostics ensures reproducible SEI formation while capturing cell-level data for binning and analytics. As a specialized partner, XINGTAI SHUODING TRADING CO.,LTD helps B2B decision makers align equipment choices with target chemistries (e.g., NMC, LFP) and form factors, shortening process development cycles and accelerating time-to-stable-yield.

Cost, Maintenance & User Experience

Total cost of ownership in battery manufacturing hinges on yield, uptime, energy consumption, and serviceability. XINGTAI SHUODING TRADING CO.,LTD designs battery manufacturing equipment for long service life using industrial components, rigid machine bases, and accessible layouts. Predictive maintenance options—such as vibration, temperature, and drive load monitoring—help schedule interventions before failures occur. Standardized spare parts, remote diagnostics, and clear documentation reduce mean time to repair and minimize inventory overhead.

From an ROI perspective, high throughput, fast changeovers, and stable process windows often outweigh initial capex. The company’s lithium battery manufacturing machine configurations emphasize energy-efficient drying, heat recovery options, and optimized vacuum usage, which can lower operating costs. User feedback in the Manufacturing of new energy equipment sector typically prioritizes intuitive HMIs, role-based permissions, and guided recipes; these features streamline training and reduce operator error. When combined with data-rich formation equipment and traceable EOL testing, manufacturers can improve yield analytics, shorten ramp-up, and reach target cost-per-Wh faster.

Sustainability & Market Trends in new energy industry

The global battery market continues to expand across EVs, stationary storage, and industrial applications, with growing emphasis on lifecycle sustainability. Regulations and customer requirements increasingly focus on carbon footprint disclosure, recycled content, and traceability (e.g., battery passports). Against this backdrop, lithium ion battery manufacturing equipment must support energy-efficient processes, minimized solvent use, and closed-loop emission control. Dry room efficiency, solvent recovery on coating lines, and intelligent power management on formation equipment are key levers for greener factories.

XINGTAI SHUODING TRADING CO.,LTD aligns with these market trends by promoting efficient layouts, energy-saving subsystems, and full digital traceability from electrode mix to shipment. By delivering battery production equipment that integrates environmental controls and process data capture, the company helps manufacturers quantify and reduce Scope 2 energy usage and material waste. This forward-looking approach enables B2B decision makers to future-proof investments, comply with evolving standards, and position their products competitively in sustainability-conscious markets.

Conclusion on battery production equipment,battery manufacturing equipment,lithium battery manufacturing machine,battery manufacturing machine,lithium ion battery manufacturing equipment,battery formation equipment from XINGTAI SHUODING TRADING CO.,LTD

From electrode lines to battery formation equipment and EOL inspection, XINGTAI SHUODING TRADING CO.,LTD provides a coherent suite of battery production equipment tailored to modern gigafactory demands. For B2B leaders in the new energy industry, these lithium ion battery manufacturing equipment solutions combine precision, uptime, and digital traceability to accelerate scale-up and control total cost per Wh. Partner with a dependable manufacturer that understands process, quality, and sustainability.

Contact us: email: sdtrading0927@126.com

Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025