Lithium Ion Battery Assembly Machine | Precision & Speed

Lithium Ion Battery Assembly Machine is a key solution in the High end equipment manufacturing industry industry, specifically within intelligent manufacturing equipment and Intelligent manufacturing equipment for lithium-ion batteries. This article explores how XINGTAI SHUODING TRADING CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Lithium Ion Battery Assembly Machine Overview

- Benefits & Use Cases of Lithium Ion Battery Assembly Machine in Intelligent manufacturing equipment for lithium-ion batteries

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in High end equipment manufacturing industry

- Conclusion on Lithium Ion Battery Assembly Machine from XINGTAI SHUODING TRADING CO.,LTD

Lithium Ion Battery Assembly Machine Overview

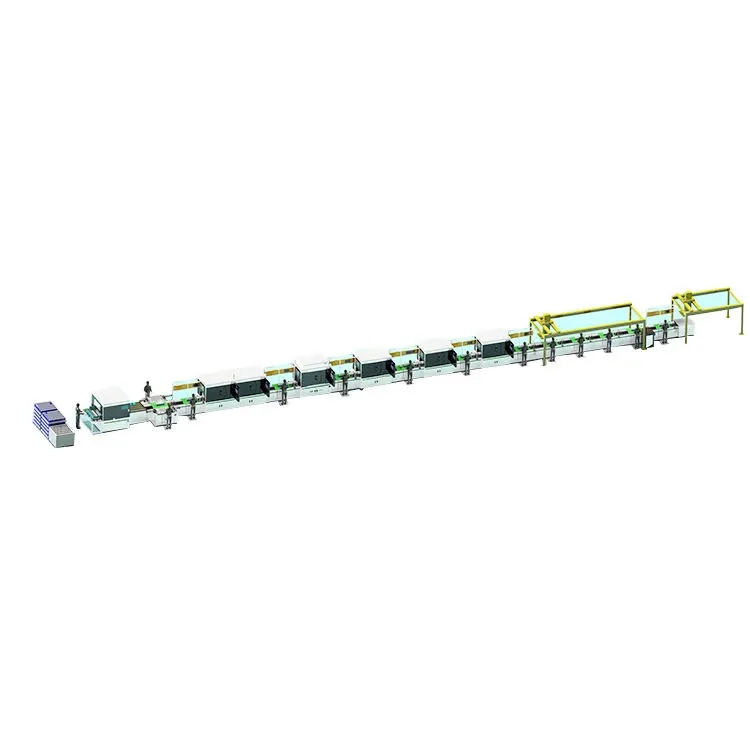

A Lithium Ion Battery Assembly Machine is the backbone of a modern battery production line, orchestrating critical steps from cell feeding and matching to module and pack assembly, busbar placement, laser welding, compression, EOL testing, and full traceability. In the intelligent manufacturing equipment domain, it enables high-throughput, consistent quality, and rapid scale-up across EV, industrial and commercial energy storage, and consumer applications. XINGTAI SHUODING TRADING CO.,LTD provides configurable systems that integrate robotics, vision-guided inspection, MES connectivity, and safety interlocks, ensuring alignment with your lithium ion battery production line strategy.

- Relevance: Combines precision motion, vision inspection, and a lithium battery welding machine (laser/ultrasonic) to deliver repeatable joints and superior pack reliability—vital for high end equipment manufacturing and long-life energy storage assets.

- Technical scope: Modular stations for cell sorting, OCV/IR testing, tab forming, busbar placement, welding, potting, sealing, torqueing, and EOL checks (insulation, leakage, functional); supports cylindrical, prismatic, and pouch cells within a unified battery production line.

- Proven partner: XINGTAI SHUODING TRADING CO.,LTD is a reliable manufacturer of lithium battery equipment, delivering turnkey integration, commissioning, and lifecycle support tailored to demanding production environments.

Benefits & Use Cases of Lithium Ion Battery Assembly Machine in Intelligent manufacturing equipment for lithium-ion batteries

Across industrial and commercial energy storage, e-mobility, power tools, and backup systems, a robust Lithium Ion Battery Assembly Machine elevates line efficiency and product consistency. For ESS and C&I projects, it ensures precise cell grouping and robust weld integrity, reducing field failures and warranty risk. For automotive modules and packs, it supports complex fixture strategies, multi-material busbars, and traceability requirements. XINGTAI SHUODING TRADING CO.,LTD’s lines integrate seamlessly with upstream and downstream processes within a full lithium battery production line.

- Applications: Cell-to-module and module-to-pack assembly, flexible format changeover (LFP/NMC chemistries), enclosure sealing, and EOL validation for both stationary storage and mobility programs.

- Advantages: Vision-guided accuracy, closed-loop welding control, digital SPC dashboards, MES/ERP connectivity, and modular expansion—ideal for scaling a lithium ion battery production line without disrupting OEE.

- Sector expertise: XINGTAI SHUODING TRADING CO.,LTD provides process development, fixture/jig customization, and integration of a high-precision lithium battery welding machine, delivering competitive cycle times and stable yields.

Cost, Maintenance & User Experience

Total cost of ownership is defined by throughput, yield, uptime, and energy consumption. XINGTAI SHUODING TRADING CO.,LTD designs for durability with industrial-grade components, accessible service points, and standardized spares to reduce MTTR. Predictive maintenance via sensor data and alarms minimizes unexpected downtime, while quick-change tooling and recipe-driven setups compress changeover windows. These factors together accelerate ROI for decision makers scaling a battery production line or upgrading legacy lithium battery equipment.

- TCO drivers: Stable yield (via inline inspection), lower scrap on welding/joining, energy-efficient drives, and remote diagnostics. The result is consistent OEE and predictable capacity planning.

- User experience: Intuitive HMI, clear fault guidance, and digital work instructions help operators ramp quickly, while engineering teams benefit from MES integration and traceability across the lithium ion battery production line.

Sustainability & Market Trends in High end equipment manufacturing industry

Global electrification, capacity expansion for energy storage, and evolving compliance frameworks (such as emerging battery passports and end‑of‑life requirements) are reshaping how factories invest in intelligent manufacturing equipment. Sustainable assembly emphasizes energy-efficient motion systems, minimal consumables in welding, and optimized material utilization. Modern lines also embed traceability and data integrity, supporting regulatory and customer audits across the value chain.

- Eco-forward design: Options for fume extraction, localized dust control, and scrap segregation (Ni/Cu/AL) help reduce environmental impact at scale.

- Future-ready: XINGTAI SHUODING TRADING CO.,LTD positions your factory for growth with modular cells-to-packs architecture, data pipelines for analytics/AI, and compatibility with evolving standards in the intelligent manufacturing equipment ecosystem.

Conclusion on Lithium Ion Battery Assembly Machine from XINGTAI SHUODING TRADING CO.,LTD

For B2B decision makers building or upgrading a lithium battery production line, a high-performance Lithium Ion Battery Assembly Machine is central to throughput, quality, and cost control. XINGTAI SHUODING TRADING CO.,LTD combines reliable lithium battery equipment, process expertise, and lifecycle support to help you scale confidently across ESS, EV, and industrial applications. Choose a partner focused on safety, flexibility, and data-driven manufacturing.

- Recap: Precision assembly, robust welding, inline inspection, and complete traceability for Intelligent manufacturing equipment for lithium-ion batteries.

- Reputation: A trusted manufacturer and integrator for scalable battery production line solutions.

- Strong CTA: Contact us: email: sdtrading0927@126.com — Visit our website: https://www.xtshuoding.com

Share

-

Lithium Battery Welding Machine | High-Precision, Fast, SafeNewsNov.17,2025

-

Aluminium Guide Roller | Anodized, Lightweight, Low-NoiseNewsNov.17,2025

-

Tofu Cat Litter Bulk – Eco, Low-Dust, Fast Clumping SupplyNewsNov.17,2025

-

Equipment for Lithium Cell Assembly | Automated & PreciseNewsNov.10,2025

-

Square File Tool – Precision Cut, Hardened Steel, VersatileNewsNov.10,2025

-

Lithium Ion Battery Assembly Machine | Automated, High-SpeedNewsNov.10,2025