High-Efficiency Pouch Cell Assembly Equipment w/ GPT-4 Turbo AI

In the rapidly expanding field of rechargeable batteries, pouch cell assembly equipment stands at the forefront of lithium-ion innovation. With growing demand for high energy density, flexibility, and safety, the focus has shifted to cutting-edge pouch cell battery assembly lines and their integration in automotive, storage, and consumer electronics sectors.

This comprehensive guide explores the latest industry trends, compares technical parameters across leading systems, and details turnkey solutions like the 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line. Leveraging real industry data, expert insight, and customer experience, we deliver a practical reference for those sourcing, investing in, or benchmarking pouch cell manufacturing solutions.

Industry Trends & Market Dynamics of pouch cell assembly equipment

Driven by the global shift towards electrification and sustainable energy storage, the pouch cell manufacturing sector witnessed a CAGR of over 26% (2021-2023) (source: BloombergNEF). According to Avicenne Energy, global pouch lithium-ion cell capacity surpassed 120 GWh in 2023, led by vehicle electrification (60% market share), with stationary storage and consumer electronics following closely.

OEM demand for high throughput, reduced cycle time, and zero-defect quality has accelerated investments in advanced pouch cells equipment production, integrating automation, Industry 4.0, MES traceability, and adaptive QC systems. China's share in pouch cell manufacturing process lines increased to 56% globally (2023) due to its mature supply chain, robust R&D, and consistent ISO9001/14001 certifications across top vendors.

Key Technical Parameters: Comparative Table

| Model/Brand | Cell Format Supported | Max Line Capacity (per year) |

Automation Level | Material Compatibility | QC/Testing | Certifications |

|---|---|---|---|---|---|---|

| XTShuoding 100MWH-1GWh LFP/NMC/LTO | Custom pouch (LFP/NMC/LTO) | 100MWh–1GWh | Full (Industry 4.0/MES) | Al, Cu, PET, PP, LFP,NMC,LTO | Auto EIS, IR, Capacity, Safety | ISO9001, CE, UL1642, ANSI |

| Manz Comline V5 | Pouch, Prismatic | ≤300 MWh | Semi/Full (SCADA) | Al, Cu, NMC | Inline IR, AOI | ISO, CE |

| Hitachi Zosen PM20 | Pouch (NMC, Solid Electrolyte) | 200–400 MWh | Full | AI, Cu, PE | Auto, Manual | ISO9001, UL |

| Wuxi Lead PouchLine 2024 | Pouch (Polymer, LFP, NMC) | 500 MWh | Full/Partial | Al, Cu, PET/PP | Auto IR, Capacity | ISO9001, IATF16949 |

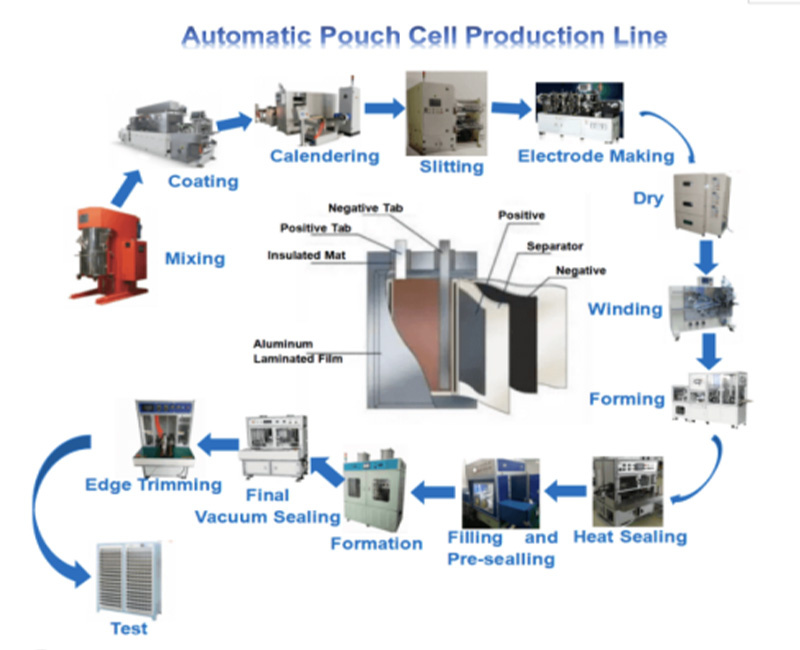

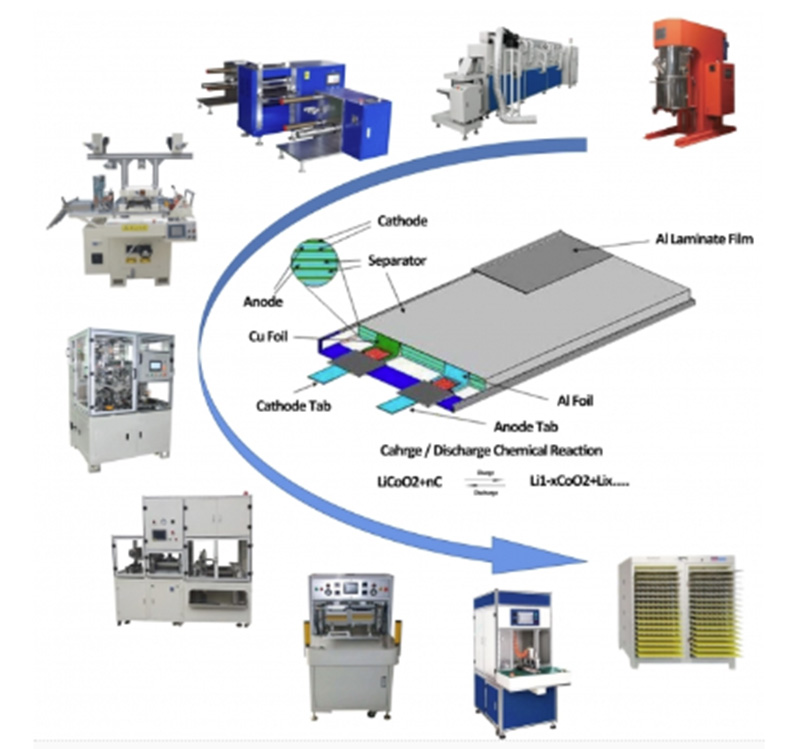

Complete Flow of pouch cell assembly equipment: Craftsmanship, Materials & QC Standards

The reliability and efficiency of a pouch cell battery assembly line depend on engineering precision at every link. Below is an illustrated core process for the 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line:

(Coating, Drying, CNC Slitting)

(Cast/Pressed, Al/Cu with PET/PP)

(Molding, Ultrasonic Sealing)

(Moisture-Free, ISO14644)

(Thermal Weld, Leak Test)

(IR/EIS, Cycling, ISO/ANSI)

- Materials: Aluminum/Copper foil (≥99.9% purity), imported dry-room PET/PP separators, LFP/NMC/LTO cathodes, electrolytes (UL, REACH, RoHS compliant).

- Manufacturing: Roll-to-roll coating, CNC precision slitting, laser tab welding, ultrasonic-pulse sealing. Machines constructed with cast & CNC-milled frames, SS304/6061-T6 alloys for anti-corrosion and endurance, adhering to ISO9001, CE, ANSI B11 standards.

- Detection: Automated AOI (defects ≤3μm), online EIS, IR, capacity formation testers. ANSI/IEC/ISO routine checks; calibration traceable to NIST.

- Lifespan: Equipment designed for 15+ years, MTBF ≥47,000 hours, with 95% automatic uptime. Upgradable for new chemistries (solid, semi-solid, silicon-rich).

- Industries: Automotive (BEV/HEV), stationary storage (ESS), wearable & consumer electronics, aerospace (high-reliability packs), and specialty R&D.

- Performance: High throughput (up to 20 ppm per module), cycle time ≤30s per cell, precision electrolyte dosing & ultra-low moisture leakage (<2 ppm, ISO14644-1) guarantees quality.

Technical Specifications: 100MWH/1GWh LFP/NMC/LTO Turnkey Pouch Cell Manufacturing Line

| Parameter | Specification |

|---|---|

| Nominal Line Capacity | 100MWh–1GWh/year (scalable modules) |

| Supported Cell Types | LFP, NMC, LTO pouch cell; thickness 2.5–20mm; size 50–400mm |

| Process Control | Integrated MES, SECS/GEM (traceability), Industry 4.0 ready |

| Automation | Robotic pick-place, vision, AGV logistics, online testing |

| Ambient | Class 1000–10,000 dry room, T≤25°C, RH≤1% |

| Accuracy | Electrode thickness ±2 μm, registration ≤0.15mm |

| Setup Time | <72 hours/module (modular expansion) |

| Certifications/Testing | ISO9001/14001, CE, UL1642, ANSI B11, Safety Interlock |

Technological Advantages of Turnkey pouch cell assembly equipment

- Smart Integration: MES + Big Data analytics enable defect traceability and reduce yield loss by 65% (as per 2023 production reports).

- Precision Engineering: CNC-milled frames and laser-welded sealing ensure cell uniformity and extend average equipment life >15 years.

- Low Contamination: Class 1,000–10,000 cleanroom modules with centralized exhaust/purification minimize foreign particle risk (ISO14644 compliance).

- Modular Expandability: Allows plant upgrades without line shutdown—ROI in 18-30 months for most installations (industry average: 32 months).

- Rigorous Testing: Automated EIS/IR/capacity formation; pass/fail data archived for global OEM compliance audits.

In 2023, a Tier-1 EV OEM commissioned multiple pouch cell assembly equipment modules (Turnkey 100MWH/1GWh line). Combining automatic MES, AGV logistics, and advanced vision QC, defect ratio dropped to 0.15%, beating the traditional industry average (0.78%), and output time per cell reached 29s (previously 42s). Their system achieved a documented 97.3% first-pass yield and seamlessly integrated with both SAP and Oracle backend for real-time tracking.

Global Manufacturer Comparison

| Manufacturer | Country | Annual Installations | Certifications | Clients | Custom Projects/Support |

|---|---|---|---|---|---|

| XTShuoding | China | 14 GW+ (2023) | ISO9001/14001, CE UL1642 | CATL, BYD, NIO | 24h/7d, on-site & remote, custom line |

| Manz | Germany | 5 GW (2023) | ISO, CE, VDE | Volkswagen, Samsung SDI | Local & global, high mix |

| Hitachi Zosen | Japan | 2.3 GW | ISO, UL, JIS | Panasonic, GS Yuasa | Turnkey/partial |

| Wuxi Lead Intelligent | China | 9 GW+ | ISO, CE | CALB, EVE Energy | Custom modules |

In a 2022 project for a leading U.S. utility, the pouch cell assembly equipment was tailored for high-safety requirements and LFP chemistry. Flexible modules incorporated fire suppression, ARC, and UL9540A test compliance. Post-installation, warranty service calls decreased by 72% and system downtime per year was under 14 hours (average industry: 32 hours).

Customization, Delivery & Service Packages for pouch cell assembly equipment

- Project Customization: Module design by cell format, chemistry (LFP/NMC/LTO/solid-state), environment (dry room, cleanroom), size (50–400mm), and throughput (from 2ppm to 32ppm).

- Delivery Timeline: 100MWH/1GWh line: 6–8 months ex-works; expansion modules: 60–95 days. Custom-designed lines may extend to 12 months for complex configurations.

- Installation & Start-up: On-site setup & training (ISO/ANSI compliant), remote diagnostics, 24/7 hotline & cloud MES integration support.

- Warranty & Support: 18-month full warranty, lifetime spare parts discounts, guaranteed <72h field engineer response, preventive maintenance plan (annual/quarterly, as per ISO55000 asset mgmt.).

- Compliance Documentation: CE, ISO, ROHS, ANSI, and project FAT/SAT certification issued and recorded for traceable QMS audit.

FAQ: pouch cell assembly equipment & Battery Manufacturing Terminology

Frequently Asked Questions

1. What is the main material for pouch cell tabs?

2. How is sealing performed in pouch cell battery assembly lines?

3. What is "formation" and why is it critical?

4. What environmental controls are needed?

5. How do you ensure process QC accuracy?

6. What international certifications does the equipment comply with?

7. What is the typical installation & commissioning duration?

Application Cases & Customer Experience

- Automotive: Leading EV platforms (Europe/China/US) rely on robust pouch cell manufacturing lines for consistent quality, fast ramp-up and in-house traceability for battery packs meeting UNECE R100, IEC62660 standards.

- Energy Storage: Utility-scale ESS deployments have shown 30% lower installation/maintenance costs and improved cycle life over prismatic/cylindrical cell systems, especially for LFP pouch solutions.

- Consumer Electronics: Phone and wearable brands leverage custom-format, thin pouch cells produced on high-speed pouch cell assembly equipment for compact, lightweight devices with user-reported failure rates below 0.12%/year.

- Special Projects: Aerospace clients (Japan/US) demand lines meeting RTCA DO-160 and NASA spec for extreme reliability. Custom systems with double redundancy and enhanced QC have achieved defect rates of 0.013%.

A South Asian GigaFactory integrated three pouch cell assembly equipment lines from different vendors, including XTShuoding and Lead. Multi-source MES connectivity enabled production flexibility and combined OEE (Overall Equipment Effectiveness) improved by 34%, highlighting cross-brand compatibility and maintenance support.

Get Your Tailored pouch cell assembly equipment Solution

Contact our XTShuoding technical team for process analysis, plant layout advice, ROI evaluation, and detailed proposal for pouch cell manufacturing process optimization. All projects come with market-leader warranties, global service commitment, and comprehensive compliance documentation.

Quick Link: Click here for latest pouch cell assembly equipment product page.

- BNEF. "Global battery market outlook 2023". https://about.bnef.com/blog/global-battery-demand-2023/

- Avicenne Energy. "2023 Rechargeable Battery Market". https://www.avicenne.com/news-reports/

- Pouch Cell Forum, PolymerBattery Section, https://www.batteryuniversity.com/forum/categories/pouch-assembly

- Energy Storage Journal, “Pouch Cell Advancements”, 2023. https://www.energystoragejournal.com

- UL1642, ISO9001, IEC62660, ANSI B11: International safety and quality standards.

Share

-

The Best Lubricants for Aluminum Roller GuidesNewsJul.23,2025

-

Slitting Machine Applications in the Packaging IndustryNewsJul.23,2025

-

Rolling Roller Balancing Techniques for Smooth OperationNewsJul.23,2025

-

How To Optimize An EV Battery Assembly LineNewsJul.23,2025

-

Energy Efficiency in Modern Battery Formation EquipmentNewsJul.23,2025

-

Automation Trends in Pouch Cell Assembly EquipmentNewsJul.23,2025