utangulizi

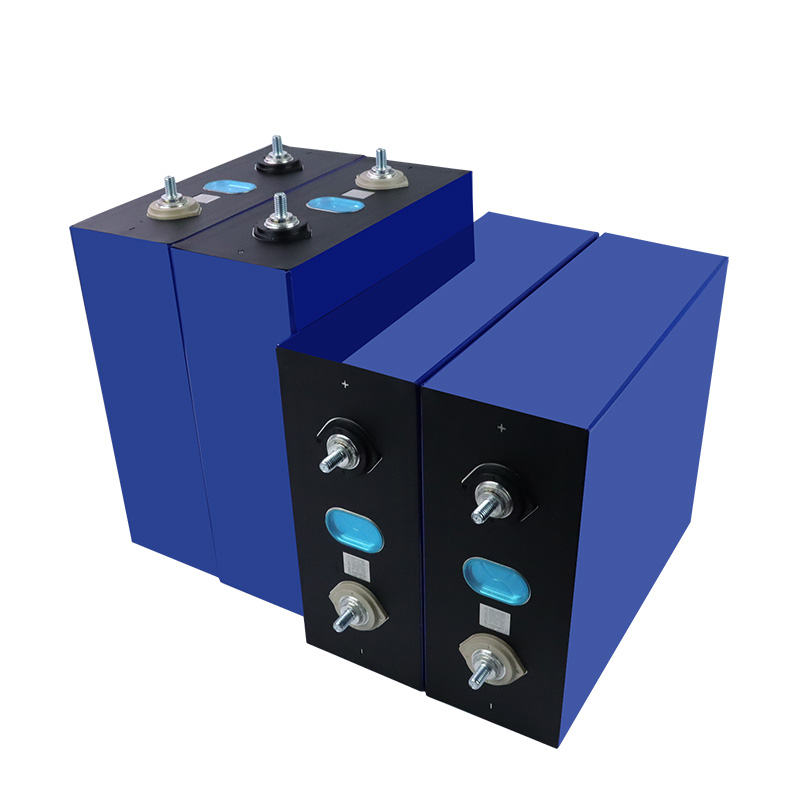

1:Prismatic Cell.

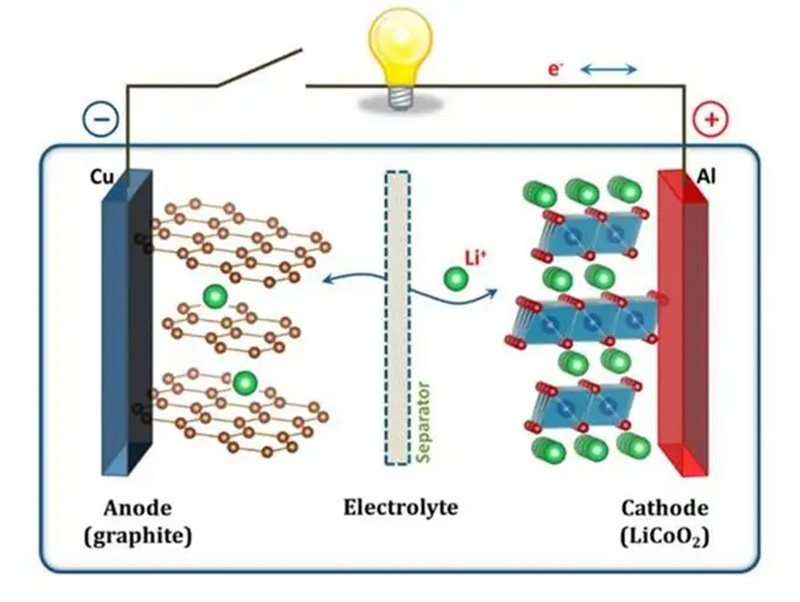

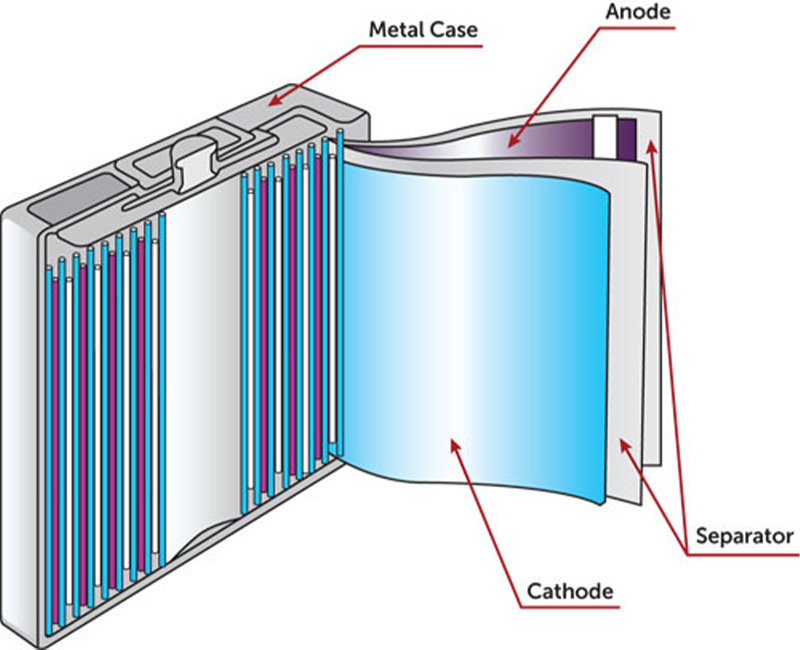

Pseli ya rismatic ni seli ambayo kemia yake imefungwa katika casing ngumu. Umbo lake la mstatili huruhusu kuweka vitengo vingi katika moduli ya betri. Kuna aina mbili za seli za prismatic: karatasi za electrode ndani ya casing (anode, separator, cathode) zimefungwa au zimevingirishwa na kupigwa.

Kwa ujazo sawa, seli za prismatiki zilizopangwa kwa rafu zinaweza kutoa nishati zaidi kwa wakati mmoja, na kutoa utendakazi bora, ilhali seli za prismatiki zilizo bapa huwa na nishati zaidi, na hivyo kutoa uimara zaidi.

2:The EV industry evolves quickly, and it’s uncertain whether prismatic cells or cylindrical cells will prevail. At the moment, cylindrical cells are more widespread in the EV industry, but there are reasons to think prismatic cells will gain in popularity.

Kwanza, seli za prismatic hutoa fursa ya kupunguza gharama kwa kupunguza idadi ya hatua za utengenezaji. Muundo wao hufanya iwezekanavyo kutengeneza seli kubwa, ambayo inapunguza idadi ya viunganisho vya umeme vinavyohitaji kusafishwa na kulehemu.

Betri za prismatiki pia ni umbizo linalofaa kwa kemia ya lithiamu-iron phosphate (LFP), mchanganyiko wa vifaa ambavyo ni vya bei nafuu na vinavyofikika zaidi. Tofauti na kemia zingine, betri za LFP hutumia rasilimali ambazo ziko kila mahali kwenye sayari. Hazihitaji nyenzo adimu na ghali kama vile nikeli na kobalti ambazo huendesha gharama ya aina nyingine za seli kupanda juu.

Kuna ishara kali kwamba seli za prismatic za LFP zinajitokeza. Huko Asia, watengenezaji wa EV tayari wanatumia betri za LiFePO4, aina ya betri ya LFP katika muundo wa prismatic. Tesla pia alisema kuwa imeanza kutumia betri za prismatic zinazotengenezwa nchini China kwa ajili ya matoleo ya anuwai ya kawaida ya magari yake.

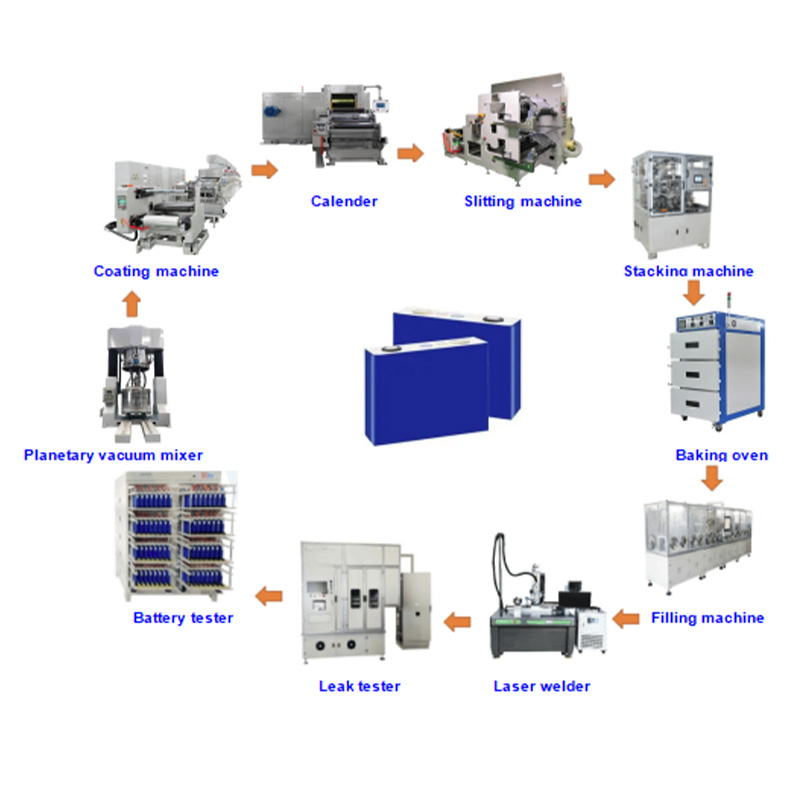

3: Equipment List.

|

SN. |

Jina la Kifaa |

|

1 |

Vifaa vya Kuchanganya |

|

2 |

Mfumo wa Kulisha |

|

3 |

Tangi ya Bafa ya Tope |

|

4 |

Auto Double Pande Slot Die Coating Machine |

|

5 |

Mfumo wa Urejeshaji wa NMP |

|

6 |

Mashine ya Kalenda |

|

7 |

Auto Slitting Machine |

|

8 |

Mashine ya Kupiga chapa |

|

9 |

Mashine ya Kupakia Kiotomatiki |

|

10 |

Mashine ya kulehemu ya Spot ya Ultrasonic (Kichupo cha kulehemu kwa kifuniko) |

|

11 |

Funika Mashine ya Kuchomelea Bamba |

|

12 |

Mashine ya Kufunga Insulator |

|

13 |

Mashine ya Kuchomea makombora |

|

14 |

Mashine ya Kupima Heliamu |

|

15 |

Mashine ya Kuosha |

|

16 |

Kipima X-ray |

|

17 |

Tanuri ya Utupu ya Juu |

|

18 |

Mashine ya Kujaza Electrolyte ya Kiotomatiki |

|

19 |

Kulowesha kwa Joto la Juu |

|

20 |

Mashine ya Kuunda Shinikizo Hasi |

|

21 |

Mashine ya Kuchomelea na Kufunga Laser |

|

22 |

Kijaribu cha OCV |

|

23 |

Mashine ya Kuchaji |

|

24 |

Mashine ya Kubandika Filamu ya PVC |

|

25 |

Kitengo cha kukausha |

|

26 |

Kitengo cha Compressor Air |

|

27 |

Kitengo cha Utupu |

|

28 |

Kitengo cha Kuzalisha Nitrojeni |

|

29 |

Deionized Maji Machine |

|

30 |

Kibaridi zaidi |

|

31 |

Kipima cha ACIR |

4: Why Choose Xingtai shuoding trading Co., Ltd?

- **Innovative Technology**: Our production lines incorporate the latest technological advancements to ensure optimal performance and reliability.

- **Customization**: We understand that each business has unique requirements. Our team can customize solutions to meet your specific production needs.

- **Support & Maintenance**: We provide comprehensive support and maintenance services to ensure your production lines operate smoothly.

- **Cost-Effectiveness**: Our solutions are designed to deliver maximum value while keeping your investments optimal.

- **Sustainability**: Our lithium battery production lines emphasize sustainability, helping you reduce your carbon footprint and contribute to a greener planet.

Habari